In a world where supply chains are being redefined, “Made in China” remains a dominant force across nearly every industry—consumer electronics, machinery, apparel, vehicles, medical devices, and beyond. This article explores the real reasons behind China’s continued manufacturing leadership in 2025, and what it means for buyers, brands, and businesses worldwide. From cost-efficiency to innovation, ESG compliance to logistics, we’ll examine why China is still the preferred partner for scaling global production.

Because it’s no longer just about low labor costs. Supporting Chinese manufacturing today means tapping into an ecosystem that delivers global efficiency, scalable flexibility, quality consistency, and technological advancement—often at a fraction of the cost and time compared to other countries. China now offers ISO-certified facilities, world-class logistics, AI-powered production, and internationally trusted brands—giving businesses not only savings, but a competitive edge in quality, delivery, and growth.

Search any product category on Google in 2025 and you’re likely to find Chinese products topping the results—not just in price, but in performance and reviews. The global conversation has shifted. Instead of asking “Is Made in China reliable?”, buyers are now wondering:“Why are Chinese products getting so good?”“Are Chinese factories better than we thought?”“Which Chinese brands can I trust?”This article dives deep into those questions—and the answers might surprise you.

Contents

- 1 What Users Are Really Searching in 2025

- 2 Misconception vs. Reality: Debunking the Stereotypes

- 3 Why Support Made in China: 7 Key Reasons

- 3.1 1. Advanced Manufacturing Capabilities

- 3.2 Centralized Ecosystem Benefits:

- 3.3 2. Scalable Supply Chains for Startups and Enterprises

- 3.4 Why This Matters:

- 3.5 3. Cutting-Edge R&D and Original Design (ODM)

- 3.6 Inside Chinese Factories:

- 3.7 4. Affordability Without Compromising Quality

- 3.8 5. Sustainability and ESG Compliance

- 3.9 ESG Advantages:

- 3.10 6. Better Logistics and Infrastructure

- 3.11 Buyer Benefits:

- 3.12 7. The Rise of Chinese Global Brands

- 3.13 Brand Success Stories:

- 3.14 What This Means for You:

- 4 What Global Buyers Say

- 5 How to Choose the Right Chinese Supplier

- 6 Buyer Questions (2025)

- 7 Chinese Smart Manufacturing Technologies to Watch

- 8 Conclusion

What Users Are Really Searching in 2025

According to Google Trends, the most searched phrases related to Chinese manufacturing in 2024–2025 include:

“Top quality Chinese brands”

“Is made in China still low quality?”

“Best Chinese factory for private label”

“Made in China vs Made in USA”

“OEM manufacturing China vs Vietnam”

These searches reflect a clear shift: buyers are not just cost-driven anymore—they want performance, reliability, and strategic production partnerships. And increasingly, they’re finding all three in modern Chinese manufacturing.

Misconception vs. Reality: Debunking the Stereotypes

| Misconception | 2025 Reality |

| “Cheap means low quality” | Chinese factories now lead in quality-control automation |

| “China copies, doesn’t innovate” | China is the global leader in patents filed in AI, EV, and 5G |

| “Factories are sweatshops” | ESG-certified smart factories are standard among tier-1 suppliers |

| “Only good for basic goods” | China builds Tesla EVs, DJI drones, Apple components, and more |

Why Support Made in China: 7 Key Reasons

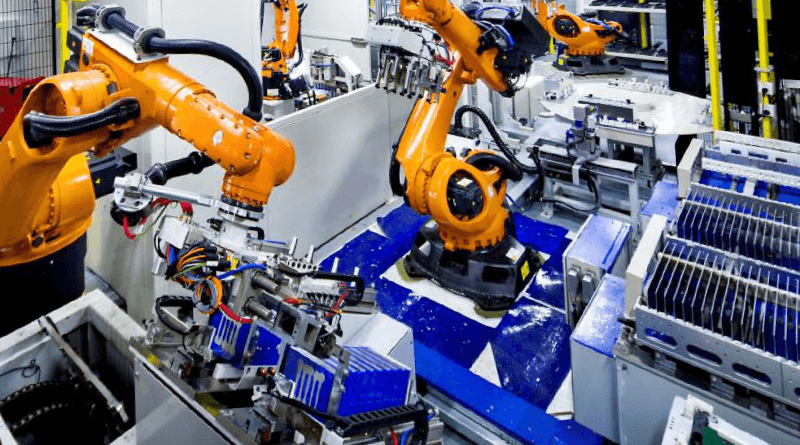

1. Advanced Manufacturing Capabilities

China is a global leader in:

- CNC precision machining

- Robotic automation

- PCB fabrication

- Smart factory integration

You get engineering-level partnerships, not just production.

Centralized Ecosystem Benefits:

- Raw materials to final product—within 100 km

- Lower total cost of ownership

- Shorter lead times

- Rapid scaling & design pivots

- Western-grade quality (Siemens/Fanuc equipment, ISO/TS certifications)

✅ Search trend: “China vs Germany CNC quality”

Answer: More Chinese factories now export to Germany as OEMs.

2. Scalable Supply Chains for Startups and Enterprises

From 100 units to a million—China scales quickly without sacrificing quality.

Thanks to:

- Modular production

- Rapid tooling

- Mature B2B platforms like Alibaba, 1688

Why This Matters:

- No need to overstock early

- Transparent supplier profiles

- Fast prototyping & sample delivery

- Localized English-speaking support

🔍 Pain point: “Other countries can’t meet MOQ flexibility”

✅ China’s edge: Digital platforms + production agility

3. Cutting-Edge R&D and Original Design (ODM)

Chinese brands are now global innovators:

- DJI dominates drones

- BYD leads EV battery tech

- Roborock, Midea, Haier set smart home standards

Inside Chinese Factories:

- AI-driven quality systems

- Collaborative robots (cobots)

- Digital twins

- Predictive maintenance

- Smart MES systems

These allow:

- High-end tech manufacturing

- Flexible product cycles

- Reduced labor costs via automation

- Traceable innovation through patents

🔍 Hot term: “Chinese drone better than DJI?”

✅ Reality: DJI is Chinese—and leads 70% of the global market.

4. Affordability Without Compromising Quality

In 2025, Chinese manufacturing offers value without compromise:

- ISO9001/13485-certified lines

- UL, CE, FDA compliance

- Multilingual contracts and support

- Up to 50% lower landed cost

Buyers report:

- Fewer defects

- Faster sample approvals

- Predictable lead times

- After-sales support with real-time tracking

🔧 Pain point: “Can I trust quality at that price?”

✅ Reality: Tier-1 factories pass EU/US audits and certifications.

5. Sustainability and ESG Compliance

China is now a green manufacturing leader:

- Solar-powered parks in Jiangsu

- Zero-discharge textile plants in Guangdong

- AI-optimized energy systems

ESG Advantages:

- ISO14001, SA8000, OEKO-TEX, LEED certifications

- Scope 3 emissions support

- Waste-minimizing practices

- ESG-ready suppliers help brands pass audits and win shelf space

🔍 Search: “ESG Chinese factory list”

✅ Fact: 300% growth in green-certified suppliers since 2020

6. Better Logistics and Infrastructure

China leads in delivery speed and reliability:

- 24/7 port automation (Shanghai, Ningbo, Shenzhen)

- High-speed rail → Europe (China-Europe Railway Express)

- Smart logistics from Cainiao, JD, SF Express

Buyer Benefits:

- Fast customs clearance

- End-to-end tracking

- Cost-effective multi-modal options

- Just-in-time (JIT) fulfillment zones

🔍 Search: “Why China still wins after COVID”

✅ Because its logistics bounced back stronger than the West’s.

7. The Rise of Chinese Global Brands

China is no longer just OEM—it’s a brand creator:

Brand Success Stories:

- Anker – Mobile power leader

- Shein – Fast-fashion disruptor

- MINNUO – Trusted medical & industrial solutions

- Lenovo – Global PC giant

- BYD & Roborock – Innovation powerhouses

What This Means for You:

- Sell trusted brands without building your own

- Faster market entry

- Existing marketing assets

- Better after-sales and warranty systems

💬 What Buyers Say:

“Our entire supply chain is China-based—99.7% on-time delivery over two years.”

“Delivery time dropped 40%, warranty claims fell to zero.”

What Global Buyers Say

“We switched from Vietnam to China for smart home parts. Delivery time dropped 40% and warranty claims fell to zero.”

— OEM partner, Germany

“Our entire supply chain is China-based and we’ve had 99.7% on-time delivery over two years.”

— US electronics startup

“We thought Chinese textile meant basic, until we saw what MINNUO and their vertical dyeing line could do.”

— Eco fashion brand, Spain

How to Choose the Right Chinese Supplier

Use this checklist when assessing a supplier from China:

✅ ISO9001 or ISO13485 certifications

✅ Transparent factory audit (video or onsite)

✅ CE/FDA compliance if applicable

✅ Supports OEM/ODM & low MOQ

Buyer Questions (2025)

“Can I get customized equipment from China?”

“What are the risks of buying from Chinese factories?”

“Which Chinese companies have real quality control?”

“How does Chinese manufacturing compare to India or Mexico?”

“Can Chinese suppliers ship DDP with tax included?”

✅ All these point to growing buyer sophistication—not fear.

Chinese Smart Manufacturing Technologies to Watch

AI-powered production lines

Cloud-based MES (Manufacturing Execution Systems)

Cobots (collaborative robots) on the assembly line

Digital twin simulations before production starts

Real-time QA tracking via blockchain

These innovations make Chinese plants more transparent and efficient than ever.

Conclusion

Supporting “Made in China” in 2025 isn’t just about price, it’s about smart sourcing in a global economy where speed, quality, sustainability and scalability are more important than ever. Whether you’re a startup, a government buyer or a tech company, choosing a Chinese supplier means you’re integrating into the world’s most advanced, adaptable and accessible manufacturing ecosystem.

At MINNUO, we help global buyers connect with top Chinese factories in the medical, industrial and energy sectors. Whether you’re sourcing oxygen generators, air compressors, cryotherapy chambers or CNC machine tools, we offer: in-house manufacturing and OEM/ODM, global certifications (CE, ISO13485, FDA if required), one-on-one sourcing and technical support, fast logistics via air/sea/rail, an English-speaking service team, contact us to find out how MINNUO can help you! Go further – Chinese quality you can trust.