In modern agriculture, the tractor has long been not a single tool for plowing, but a set of plowing, planting, application, harvesting, transportation in one of the integrated operating platform. Whether it is field farming, orchard management, or mountain transportation, the tractor is the core power bridge between the land and crops. Its attendance, load capacity and adaptability directly determine the productivity and operational rhythm of a farm.

However, in the actual purchase or use of the process, many users tend to focus only on the “horsepower” or “brand price”, but ignored the decision to determine the core of the performance and life of the tractor – the key components. Key components. Especially as the power source of the engine, its quality, not only affects the operating efficiency, but also determines the later maintenance costs and reliability.

So the question is: in a tractor’s many parts, in the end, which is really affecting the performance and operational value of the “core parts”? This article will take you to find out, from the technical logic and actual cases, interpretation of “the most important parts of the tractor in the end is what”, and provide evidence-based recommendations for the purchase, to help you choose accurate, stable use.

Contents

- 1 1.Parts inventory: tractor “core competitiveness” from where?

- 1.1 Multi-angle comparison: not only look at the “horsepower”, but also look at the “matching degree”

- 1.1.1 1.1 Without the cooperation of the gearbox, the engine is no longer strong, but also can not be pushed to the ground

- 1.1.2 1.2 Without hydraulics, you can’t “hold the tool”

- 1.1.3 1.3 3-point suspension is the “compatibility force” that determines how many tools can be hooked up and how stable they are.

- 1.1 Multi-angle comparison: not only look at the “horsepower”, but also look at the “matching degree”

- 2 2. Focus on analysis: the engine – the tractor’s “heart”

- 2.1 Why is the engine the most central component?

- 2.1.1 Power output determines implement capacity and operating range

- 2.1.2 High torque supports the ability to cope with complex working conditions.

- 2.1.3 Continuous operation depends on engine health

- 2.1.4 Comparison of different engine types: diesel vs gasoline vs electric

- 2.1.5 Consequences of engine failure: the most direct impact, the most serious losses

- 2.1 Why is the engine the most central component?

- 3 3.Case verification: three real scenes to prove that “the engine is king”

- 3.1 3.1 Big field cultivation: high-horsepower engine supports compound operation

- 3.2 Background:

- 3.3 Role of engine:

- 3.4 3.2 Mountain slope transportation: high torque + stable output = anti-skid guarantee

- 3.5 Problem background:

- 3.6 Role of the engine:

- 3.7 3.3 Multi-functional operation: engine + hydraulic + PTO synergy determines the adaptability of the whole machine

- 3.8 Problem background:

- 3.9 Role of the engine:

- 4 4. Is it unique? The “multiplier effect” of other components on performance

- 5 5. Purchase advice: how to judge the engine good or bad?

- 5.1 5.1 Look at the parameters: three indicators to determine “whether the power”

- 5.2 5.2 Look at the brand: Priority should be given to the “system, reputation” of the engine manufacturers

- 5.3 5.3 Look at the working conditions: not all engines can “do heavy work and resist extremes”.

- 5.4 5.4 Look at the fuel consumption and maintenance cycle: to determine the long-term operating costs of the “invisible books”

- 6 Conclusion

1.Parts inventory: tractor “core competitiveness” from where?

Tractor performance is not determined by a single component, but is the result of the synergistic operation of several key systems. The following is an analysis of the role and status of the seven key systems in the operation, which reveals which part is the real “core strength”.

| Part Name | Functions | Is it the key | Applications |

| Engine | Provide the power output of the whole machine | Source of powerful power | determines the ability to haul heavy loads and cope with high resistance tillage; lack of horsepower directly limits efficiency. |

| Transmission | Control the speed and torque transmission | Key to switching working conditions | Transitioning from flat to hilly and from towing to transporting requires variable speeds, especially gear range and smoothness. |

| Hydraulic System | Control the lifting, mounting and hoisting force | Core of operational efficiency | Mostly used for lifting plows and hanging implements, which is the basis for fine agronomic adjustment. |

| Drive Axle | Realize four-wheel drive, anti-skidding | Core of land-adapted capability | Slippery farmland requires sufficient grip, front and rear axle linkage is the key configuration. |

| Cooling System | Control the temperature, protect the engine | Operational stability guarantee | High-temperature operations (e.g. midday plowing in summer) must rely on stable heat dissipation, otherwise they are prone to stalling or wear and tear. |

| Three-Point Suspension System | Connect the agricultural tools, load-bearing work | Compatible platform for farm machinery | The premise of tractor multifunctionality determines the type and stability of the adapted implements. |

| Electronic Control System | Intelligent control, precise management | Key entrance to intelligent agriculture | The core upgrading point of future agriculture, PTO automatic start-stop, self-adjustment of plowing depth, remote fault reminder, etc. all rely on this system. |

Multi-angle comparison: not only look at the “horsepower”, but also look at the “matching degree”

1.1 Without the cooperation of the gearbox, the engine is no longer strong, but also can not be pushed to the ground

The engine provides the power, but the terrain and load changes need to be “gear” adjusted output; multi-gear synchronizer transmission + dual clutch shift technology is more suitable for modern composite work. The engine provides power, but terrain and load changes require “variable speed” to adjust the output;

multi-gear synchronizer transmission + dual clutch shift technology is more suitable for modern composite operations.

1.2 Without hydraulics, you can’t “hold the tool”

Plows, planters, mowers and other agricultural tools rely on hydraulics for mounting, lifting and depth control;

The faster and more accurate the hydraulic response, the higher the operating efficiency, especially in starting and turning.

1.3 3-point suspension is the “compatibility force” that determines how many tools can be hooked up and how stable they are.

A small horse-drawn vehicle? Can not hang or hang unstable;

Excellent three-point structure can ensure that the tool does not swing or shake excessively when applying fertilizer and dosing operations, reducing the error rate.

2. Focus on analysis: the engine – the tractor’s “heart”

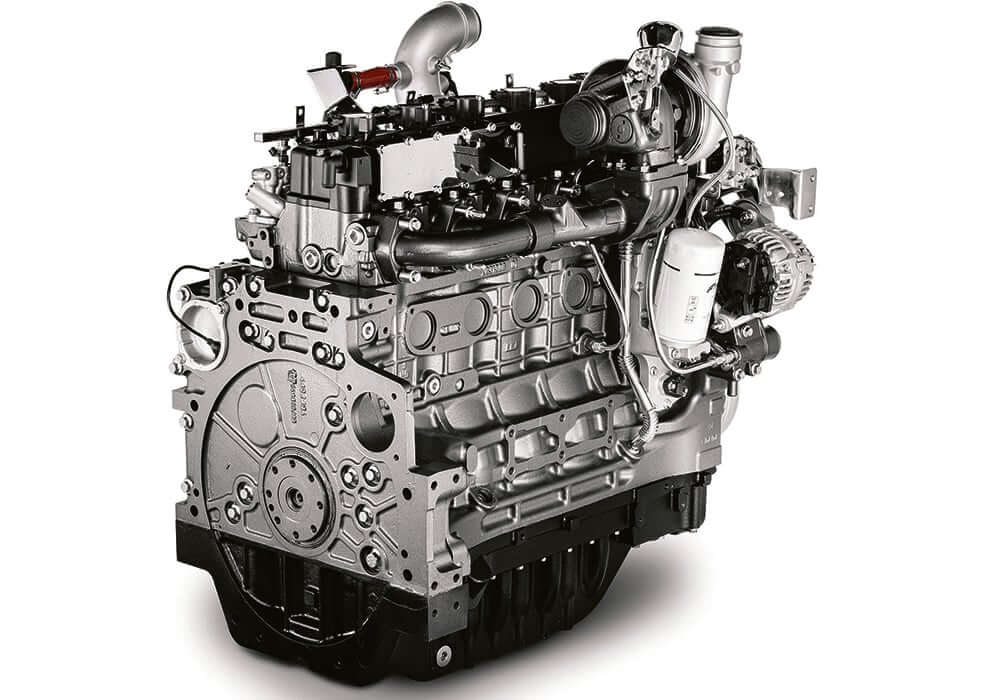

In all the tractor system, the engine is recognized as the “most critical” power core, its performance directly determines the whole machine Its performance directly determines whether the whole machine can operate efficiently, adapt to complex terrain, mounting heavy farm equipment, and even affect the economy and service life of the machine.

Why is the engine the most central component?

Power output determines implement capacity and operating range

The types of implements that can be mounted on a tractor and the upper limit of its operating efficiency are directly limited by the horsepower of its engine. Whether it is a seeder, a deep pine shovel, a rotary plow, a lawn mower or a fertilizer spraying system, insufficient power means slow operation speed, small one-time operation range, or even the inability to mount a specific tool.

High torque supports the ability to cope with complex working conditions.

engines are not only strong, but also stable. In complex fields such as wet sticky soil, hilly terrain, and clay-sand composite geology, whether or not the engine has sustained high torque output will directly affect whether or not it can start smoothly, climb slopes, or drag farm implements.

Continuous operation depends on engine health

The thermal stability, durability and cold-start capability of the engine are especially important for continuous operation in large fields. For example, if the engine overheats and stalls during a long plowing period in the spring, it will lead to interruption of operation, re-hanging of implements, and even delay in sowing, which is a huge loss.

Comparison of different engine types: diesel vs gasoline vs electric

| Engine Type | Features | Scenarios | Advantages and disadvantages in brief |

| Diesel Engine | High torque, strong low speed | Heavy tillage, transportation | Most common, suitable for high-horsepower tractors, durable but high vibration, need regular maintenance |

| Gasoline Engine | Quick start, low cost | Small orchards, light work | Low cost but low torque, suitable for small horsepower light load use |

| Electric Powertrain | Clean, low noise | Facility agriculture, smart farms | Environmentally friendly but limited range, suitable for short-range multi-operation scenarios |

Current trend: the mainstream market is still dominated by diesel, but in the direction of intelligent agricultural machinery and new energy, some companies are laying out the electric tractor pilot.

Consequences of engine failure: the most direct impact, the most serious losses

Once the engine failure, not only “power output decline” so simple, but also directly cause the whole machine shutdown, the tractor will not be able to move forward, can not lift the agricultural tools, and even lost directional control.

In contrast, the hydraulic system, electronic control system failure, there is still “maintain operation + temporary adjustment” of the margin, while the engine problem, the result is usually only one: the tractor stopped in the field can not move.

Common fatal faults such as:

Low oil pressure → wear and tear

Cylinder block overheating → valve deformation

Inadequate combustion → excessive emissions + reduced power

Starter motor failure → cannot start

3.Case verification: three real scenes to prove that “the engine is king”

In the selection of agricultural machinery, many users often focus on the peripheral experience of tractor, such as “more features” and “whether it has air conditioning”, but only after really entering the high-intensity operation scene do they realize that “whether it has the strength to withstand the scene” is the key. The following three typical real-life cases verify the decisive influence of engine performance on tractor experience from different dimensions.

3.1 Big field cultivation: high-horsepower engine supports compound operation

Scene type: sowing + tilling + soil cultivation combined operation

Terrain: sticky soil, thick layer

Key demand: one-time completion of the operation, reduce round trip

Background:

When traditional tractor is mounted with multifunctional compound operation implements (such as deep pine tilling combine), it is often unable to maintain the depth of implements’ downward pressure due to insufficient power, or power output is unstable in the field turning, leading to breakage under heavy loads.

Role of engine:

MINNUO model adopts high-horsepower (≥120hp) diesel engine, with high torque reserve, even at low speed, it can maintain stable traction and ensure the smooth completion of multi-tillage work.

Effect feedback: the same plot of land operation time is shortened by 21%, fuel consumption is reduced by nearly 14%, and secondary plowing is avoided.

3.2 Mountain slope transportation: high torque + stable output = anti-skid guarantee

Scene type: slope transfer seedlings + water tank

Terrain: slippery slopes, uneven road conditions

Demand key: uphill traction, downhill braking stability

Problem background:

Part of the mountainous area orchards/tea gardens using a lightweight, small horsepower model, the engine load rises dramatically on slopes, and the unstable output leads to the “push”, and in severe cases, even the “push”. “and in serious cases, even stalled downhill, extremely unsafe.

Role of the engine:

MINNUO is equipped with a high-pressure common rail diesel engine with automatic torque compensation function, even when the gradient changes, the engine can quickly recognize the load changes and provide continuous thrust, with the four-wheel drive axle system, effectively preventing skidding or “rushing slope”.

Feedback: the average time of uphill is shortened by 30%, the downhill steady state control response is improved by 45%, and the continuity of transportation operation is improved obviously.

3.3 Multi-functional operation: engine + hydraulic + PTO synergy determines the adaptability of the whole machine

Scene type: orchard mowing + herbicidal + rotary tillage rotational operation

Key challenge: frequent tool change, changing operational rhythm

Problem background:

Many orchard users encounter “power can not take the hydraulic pump” when using multi-functional tractor, “PTO output is unstable”. Especially when mowing and dosing are mounted at the same time, it is extremely sensitive to the engine output response.

Role of the engine:

MINNUO model can realize intelligent loading of different operation modules through the linkage partition management system of the engine and hydraulic pump + PTO output, which not only avoids “overloading”, but also maintains smooth output.

Feedback: Completing three kinds of operations in the same day reduces the number of round trips, improves efficiency by 32%, and effectively reduces the changeover time and the cost of manual adjustment.

4. Is it unique? The “multiplier effect” of other components on performance

Although the engine is the “heart” of the tractor, whether the performance of the whole machine can be truly released depends on the coordinated work of a whole set of key components. Power ≠ capacity, transmission mechanism and control logic are equally important.

Without a strong transmission, the power can’t run far.

Principle:

The engine output is the original power, but this power needs to be adjusted and distributed by the transmission in order to adapt to the ever-changing speed and load requirements in farmland operations.

Heavy plowing conditions: low speed and high torque are required, testing the stability of low gear output;

Transit transportation conditions: high speed and low fuel consumption are required, testing the smoothness of high gear.

If the transmission structure is backward or the gears are not reasonable, even if the horsepower is strong, it may “idle” or even “hit the teeth”, which seriously affects the energy efficiency ratio.

Hydraulic system is the core collaborator of “precision operation”

Principle description:

Many high-precision operations of modern tractors, such as lifting, suspension, leveling, and sowing depth adjustment, rely almost entirely on the hydraulic system. Even if the engine output is smooth, if the hydraulic system reacts slowly and does not have enough pressure, the implements will not be able to work accurately.

In plowing: hydraulic quick lifting and lowering can improve turning efficiency;

In fertilizing: stable hydraulic pressure determines the width and uniformity of fertilizer application;

In planting: hydraulic depth control affects the consistency of seedling emergence.

Precision does not mean horsepower, the hydraulic system determines the “fineness of work”.

Electronic control system is the future performance of the release of the “control brain”

With the development of intelligent agricultural machinery, the tractor is not only “able to run”, but also “can adjust, can remember, can be automatically “. The electronic control system is the basis of these advanced functions.

Engine speed control, PTO start-stop, hydraulic flow matching, remote data upload, all rely on highly reliable CAN bus electronic control module.

Intelligent regulation modes (e.g. operating mode switching) can significantly improve the efficiency of multifunctional operations.

Without electronic control, even if a single component is excellent, the overall performance will be greatly reduced.

5. Purchase advice: how to judge the engine good or bad?

Engine as the tractor’s “heart”, directly related to the traction capacity of the machine, operational stability and late use of cost. Correctly identify the “engine good or bad”, not only to choose the right product, but also to avoid the risk of low efficiency and high maintenance investment.

5.1 Look at the parameters: three indicators to determine “whether the power”

Rated horsepower (kW / HP): to match the operational needs, for example, planting type tractor is generally ≥ 80HP, orchard type of 40-60HP;

Maximum torque (Nm): to determine the heavy-duty start and climbing ability, it is recommended to pay attention to the torque output of the low-speed section is sufficient;

Speed range (RPM): too high, easy to consume fuel, easy to wear, reasonable range such as 1800~2300RPM is more stable.

Suggestions: when choosing a machine, do not just look at the “horsepower value”, combined with speed and torque to see the power curve.

5.2 Look at the brand: Priority should be given to the “system, reputation” of the engine manufacturers

big brands usually represent mature technology, strong common parts, perfect after-sales service.

International famous brands: Cummins, John Deere, Komatsu, Yanmar

Domestic mature brands: Weichai, Yuchai, Changchai, Shangchai, etc.

Preferred principle: brands with local service outlets and authorized spare parts channels are more trustworthy.

5.3 Look at the working conditions: not all engines can “do heavy work and resist extremes”.

Year-round plateau/low-temperature areas: choose models with cold-starting assistance systems (such as preheating plugs and pressurization devices).

Heavy loads/all-weather operation: it is recommended to choose industrial/heavy-duty engines with supercharged intercooling and cylinder reinforcement.

Orchard operation/light-duty use: choose industrial engines with supercharged intercooling and cylinder reinforcement. Heavy duty/all-weather operation: it is recommended to choose the industrial/heavy duty engine with supercharged intercooler, cylinder reinforcement, etc.; Orchard operation/light duty use: it is possible to choose an economical gasoline engine, which is light and quick to start, but the time of continuous loading should be controlled.

Tip: engine selection can not be “one size fits all”, and should be based on the premise of operating intensity + site conditions.

5.4 Look at the fuel consumption and maintenance cycle: to determine the long-term operating costs of the “invisible books”

Fuel consumption directly affects the unit operating costs, a fuel-efficient engine, you can save thousands of dollars per year;

Formal manufacturers of engines have recommended oil replacement cycles and air filter maintenance specifications, it is recommended to choose a longer maintenance cycle, maintenance more convenient brand;whether to support local common oil products; the engine should be used in the engine.

whether to support local common oil also need to confirm in advance to avoid the problem of adding the recommended oil.

Suggestion: require manufacturers to provide engine “annual operating cost estimate” report, as a reference for selection.

Conclusion

The reason why a tractor can become a main tool in the farmland lies in whether it has a stable and powerful “heart” – the engine. Horsepower, torque, fuel efficiency, reliability …… each performance indicator determines whether it is capable of deep plowing, rotary plowing, transportation, seeding and other heavy operations.

Through the analysis of this article, we can easily see: the engine is not the “only”, but must be the “core”. And it and transmission, hydraulic system, electronic control and other components of the degree of cooperation, will jointly determine whether the machine can really release all the strength.

As a brand focusing on high-performance agricultural machinery solutions, MINNUO always takes engine performance matching as the primary starting point of the machine design. From power selection to system linkage, from daily operation and maintenance to intelligent control, MINNUO is committed to letting every farmer not only buy a tractor, but also choose the right one with a “safe heart”.

The future of agricultural mechanization is not just “buying a car”, but “choosing a heart”.