In modern agriculture, seed sorter is the key to a bountiful harvest, and a seed sorter is the tool that unlocks it! With the rise of smart agriculture, AI sorting, and precision farming, every farm owner wants their seed sorter to be more than just a “filter” but a smart, efficient “seed detective.” This detective’s job is to identify healthy, plump seeds while keeping poor-quality ones out of the mix. Nowadays, the seed market is no small feat—it’s all about data, efficiency, and intelligent tech, since farming has truly gone high-tech.

Throughout the sorting process, seed quality varies greatly, and each crop has its own specific quality standards. This means selecting the right seed sorter involves several factors, like seed characteristics, sorting accuracy, efficiency, and maintenance costs. Plus, as demand for high-yield crops grows, the return on investment (ROI) of a seed sorter becomes crucial. So, farmers and producers need to factor in not only the initial purchase price but also long-term operational costs, such as energy consumption, upkeep, and labor needs.

To address these considerations, the next sections will cover the main types of seed sorters, key points to consider when choosing one, and practical applications for different scenarios. This guide will help you make smart decisions on a seed sorter that works for you and your farm’s goals.

Contents

- 1 What is a Seed Sorter?

- 2 How a Seed Sorter Works

- 3 Types of Seed Sorters: Which One Fits Your Needs Best?

- 4 Choosing the Right Seed Sorter: A Step-by-Step Decision Guide

- 5 Recommended Options for Different Farming Scenarios

- 6 Common Questions and Answers

- 7 Conclusion: Finding the Right Seed Sorter for Your Farm

What is a Seed Sorter?

A seed sorter, as its name suggests, works as a dedicated machine for sorting seeds. It selects quality seeds based on their size, weight, shape, density, and even visual traits like color or surface flaws. This machine effectively screens out low-quality seeds that don’t meet specific standards and ensures only healthy, top-quality seeds make the cut. By using a seed sorter, growers save on labor costs while securing high-quality seeds for planting.

How a Seed Sorter Works

The working principle behind a seed sorter varies depending on the technology, though it typically relies on a few main methods:

- Physical Sorting: This method separates seeds based on size, weight, and shape differences. It uses vibrations, airflow, and mesh screens to categorize seeds. Physical sorting often suits larger crops with distinct density differences, like corn or soybeans.

- Optical and Image Recognition: Using high-resolution cameras, this method captures and analyzes the surface features of seeds, such as color, shape, and imperfections. Image recognition technology then determines seed quality, allowing for precise sorting, making it ideal for high-value crops like fruits and vegetables.

- Airflow Separation: Airflow-based sorting relies on density differences among seeds, making it especially suitable for beans and similar crops. By controlling airflow, it easily separates seeds of varying quality.

Each of these seed sorting methods can function independently or combine to meet the specific needs of different crops and production scales.

Types of Seed Sorters: Which One Fits Your Needs Best?

Physical Seed Sorter — “Classic and Reliable for Basic Sorting”

The physical seed sorter is a true “classic” in seed sorting technology. With a simple design that relies on airflow and mesh screens, it easily separates heavier, larger seeds from any mixed-in debris. This type of sorter is ideal for small- to medium-sized farms and for basic crop sorting needs. Think of it as a “no-fail starter option” for farmers who want reliability without the hassle.

- Suitable Crops: Larger seeds with distinct features, such as wheat and corn.

- Advantages: Affordable, easy to maintain, and simple to operate, making it a great choice for those on a limited budget.

- Limitations: Limited sorting precision; it struggles with detecting internal defects in seeds, and its range of applications is narrower.

Optical Seed Sorter — “Precision Tool for High-Value Crops”

The optical seed sorter introduces image recognition and data analysis to seed sorting, taking accuracy to the next level. High-definition cameras detect color, shape, and surface defects in seeds, removing any with visible flaws, disease, or damage. This high-tech equipment shines in the production of high-value crops like vegetables and fruits, where quality is a top priority.

- Suitable Crops: Primarily high-value crops such as vegetables and fruits.

- Advantages: High precision sorting significantly boosts crop purity and germination rates, providing top-tier seed quality assurance.

- Limitations: Higher price tag and requires technical support, making it a better fit for medium to large farms with high yield and quality demands.

Airflow Seed Sorter — “Density Specialist for Beans and Similar Crops”

Simple but effective, the airflow seed sorter relies on adjustable airflow to separate seeds based on density. It’s particularly useful for crops with a noticeable density difference, like beans, where it shows impressive results in sorting by quality. Its straightforward design and ease of use make it a go-to tool for specialized operations.Our airflow seed sorter provides the precision needed to optimize the sorting process for crops with density differences.Here’s how it stands out:

- Suitable Crops: Crops with density variations, like beans, or seeds that require high purity.

- Advantages: Easy to use and capable of significantly enhancing seed consistency and purity.

- Limitations: Limited to specific crops, mainly those with density differences.

Our airflow seed sorter provides the precision needed to optimize the sorting process for crops with density differences.Here’s how it stands out:

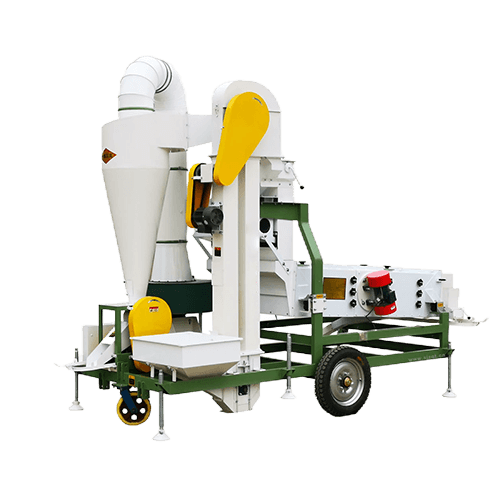

Small air sieve cleaning machine 5XZC series is mainly by vertical air sieve and vibrating screen to complete the sorting function. Can be a variety of crop seeds (such as: wheat, corn, soybeans, melon seeds, sesame, rapeseed, etc.) for wind selection, screening processing to achieve the purpose of crop cleaning, and can be used as a grading machine. This machine is composed of lifting device, screening device, wind selection device, electric control device, dust removal device and walking device. The whole machine is easy to clean and can effectively prevent mixing and ensure the purity of seeds.

Smart Seed Sorter — “The Ultimate Seed Sorting Assistant”

With IoT and big data shaping today’s agriculture, the smart seed sorter serves as an “AI assistant” on the field. Combining optical detection, data monitoring, and remote control, it continuously adjusts sorting parameters to match various seed types. This sorter provides real-time data updates, making it ideal for large farms or research settings that require precise monitoring.

- Suitable Crops: A variety of crops with precise sorting needs, such as those on large farms or research facilities.

- Advantages: Highly automated, flexible, and precise, with remote monitoring capabilities, making it the ultimate “smart guardian” of seed quality.

- Limitations: Higher costs and requires technical support, making it best suited for farms with larger budgets.

Choosing the Right Seed Sorter: A Step-by-Step Decision Guide

Finding the right seed sorter requires weighing various factors to ensure the equipment fits your budget while boosting production efficiency. Follow these steps to assess your needs and make an informed choice:

Step 1: Determine Crop Type and Sorting Requirements

Different crops have unique sorting standards and quality requirements. For example, if you primarily grow large-seed crops like corn or soybeans, a physical seed sorter can work well. But if you grow higher-quality crops (like fruits and vegetables), an optical or smart seed sorter might be better suited to meet the quality demand.

- Tip: List your main crops and analyze each crop’s sorting needs. Decide whether you need high precision or purity to choose the right equipment type.

Step 2: Evaluate Sorting Precision and Production Efficiency

The sorter’s precision and speed will directly impact production. Farms with high output need fast, precise equipment. Smart or optical sorters excel here, while small- and medium-sized farms may find a physical sorter adequate for daily tasks.

- Tip: Assess your farm’s size and daily sorting volume. Prioritize models with high automation and sorting speed to improve production efficiency.

Step 3: Consider Equipment Versatility and Flexibility

For farms that grow multiple crops, choosing a versatile sorter offers economic benefits. Smart sorters with automatic adjustment and multi-mode settings handle various crop sorting needs with minimal downtime between adjustments.

- Tip: Multi-crop farms should consider smart models that support multiple sorting modes. Ensure the device is easy to operate and quickly adapts to changing crop requirements.

Step 4: Analyze Long-Term Costs

Total cost includes not only the initial purchase price but also daily maintenance, power usage, and labor costs. Physical sorters generally require less maintenance, whereas smart and optical models need more technical support and investment.

- Tip: List the initial purchase price, maintenance fees, and power costs to compare different models’ long-term cost-effectiveness.

Recommended Options for Different Farming Scenarios

Small Family Farms

For small family farms, a simple, user-friendly physical seed sorter offers great value. These machines provide a cost-effective solution for basic sorting needs, making them ideal for small-scale daily use.

Mid- to Large-Scale Farms

For mid- to large-scale farms, consider using an optical or airflow seed sorter. An optical sorter boosts seed purity and lowers manual sorting costs, while an airflow sorter is better suited for density-varied crops like beans.

High-End Farming and Research Projects

For high-end or research-focused projects, a smart seed sorter with data monitoring and remote control features provides precision management. Its data analysis capabilities add value by improving seed purity and uniformity while supporting advanced agricultural research.

Common Questions and Answers

When selecting a seed sorter, farmers often encounter similar questions. Here are some detailed answers to help guide you toward a smarter choice:

Is a physical seed sorter suitable for all crop types?

A physical seed sorter works well for larger, heavier seeds like corn and wheat. However, for smaller, denser crops like rapeseed, its effectiveness may be limited. In such cases, consider using an optical or airflow sorter to improve purity.

Is the high cost of an optical seed sorter worth it?

For high-value crops, an optical sorter’s high-precision filtering can increase germination rates and reduce the impact of low-quality seeds, delivering faster returns. Farms with large planting areas and high seed quality standards can achieve significant yield improvements with this equipment.

How does a smart seed sorter enhance sorting efficiency?

Smart sorters offer automatic adjustment and real-time monitoring to adapt to different crop needs. They reduce manual input while providing precise sorting. Their data analysis capabilities also help optimize sorting processes, lower defect rates, and meet the demands of large-scale farming or research.

Conclusion: Finding the Right Seed Sorter for Your Farm

Choosing the right seed sorter not only lays the groundwork for higher yields and quality crops but also helps reduce long-term production costs, ultimately leading to a better return on investment. This guide, with its technical breakdown, step-by-step selection advice, and answers to common questions, aims to provide you with the scientific support needed to make the best decision. If you have specific needs during your selection process, feel free to reach out to our expert team. We’re here to provide tailored seed sorter solutions that empower you to achieve efficient and effective production on your farm.