- Home

- Products

- Reprocessing Machinery

- Sorting Machine

- Compound Grain Cleaning Machine 5XF Series

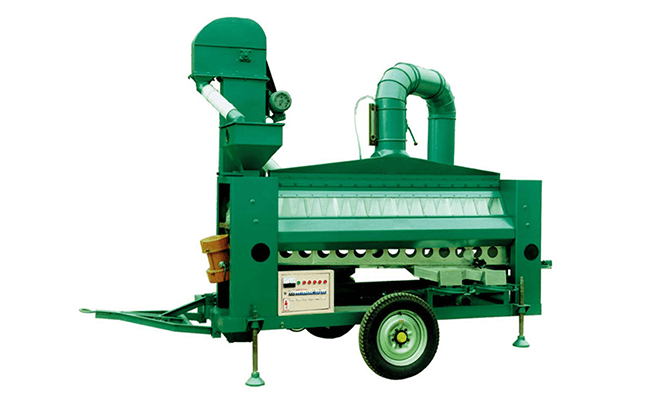

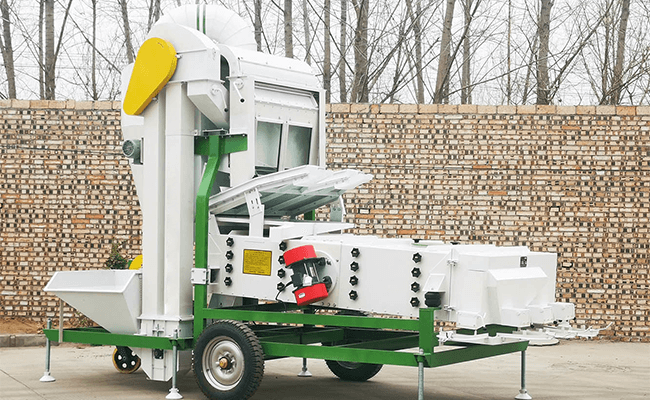

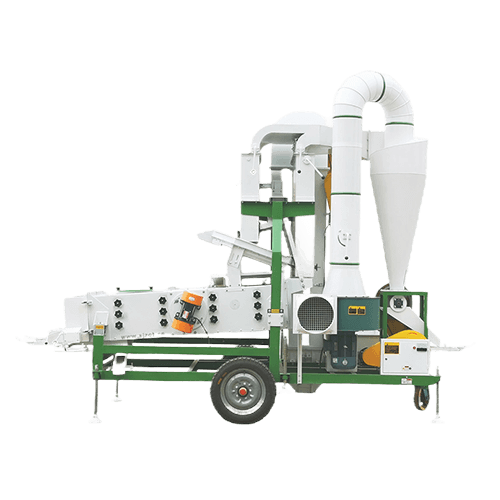

Compound Grain Cleaning Machine 5XF Series

Compound grain air sieve cleaner 5XF series mainly relies on vertical air sieve, de-stoning mechanism and vibrating screen to complete the sorting function, which can separate the gravel and soil particles in the grains to be discharged from the stone outlet.

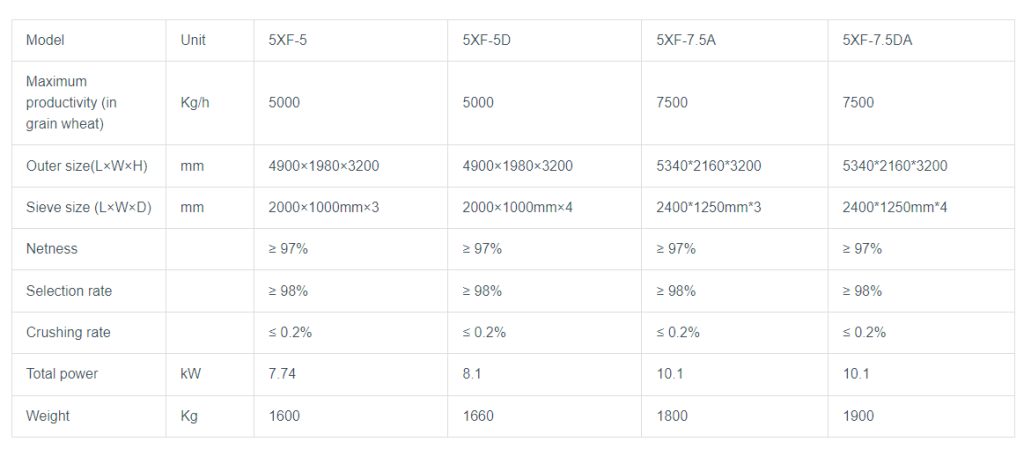

parameters

| Model | Unit | 5XF-5 | 5XF-5D | 5XF-7.5A | 5XF-7.5DA |

| Maximum productivity (in grain wheat) | Kg/h | 5000 | 5000 | 7500 | 7500 |

| Outer size(L×W×H) | mm | 4900×1980×3200 | 4900×1980×3200 | 5340*2160*3200 | 5340*2160*3200 |

| Sieve size (L×W×D) | mm | 2000×1000mm×3 | 2000×1000mm×4 | 2400*1250mm*3 | 2400*1250mm*4 |

| Netness | ≥ 97% | ≥ 97% | ≥ 97% | ≥ 97% | |

| Selection rate | ≥ 98% | ≥ 98% | ≥ 98% | ≥ 98% | |

| Crushing rate | ≤ 0.2% | ≤ 0.2% | ≤ 0.2% | ≤ 0.2% | |

| Total power | kW | 7.74 | 8.1 | 10.1 | 10.1 |

| Weight | Kg | 1600 | 1660 | 1800 | 1900 |

Features

- Grain cleaner sieve is made of cold rolled galvanized steel plate with high precision and long life.

- Equipped with a de-stoning mechanism, it can remove most of the sand, gravel, soil particles and other heavy impurities, which makes it a multi-purpose machine.

- Adopting vibration motor as vibration source, it is convenient and accurate to adjust the required amplitude and vibration direction angle.

- Equipped with spiral dust removal device, can effectively reduce the working environment dust, to meet the environmental requirements.

- Wide range of application, can be used in grain processing and agricultural by-products processing industry.

- Easy to operate, convenient to move, reliable work.

Working Principle

Compound grain cleaner 5XF series according to the aerodynamic characteristics of the seeds, according to the different critical speed of the grain and impurities, by adjusting the speed of the airflow, to achieve the purpose of separation, lighter impurities are sucked into the dust collector to concentrate on the discharge, the better grain through the double vertical air sieve into the vibrating screen is located in the feed end of the gravel institutions, the material through the fish scale sieve plate friction, the material in the sand, gravel and soil particles separated from the discharge of stone. The material will be separated from the gravel and soil particles in the material by the friction of fish scale screen plate and discharged from the stone outlet.

After the de-stoning processed materials into the vibrating screen. The vibrating screen can discharge the large impurities, small impurities and selected grains separately (we can also provide four-layer, multi-layer screen box series products, cleaning and grading can be completed at once). Vibrating screen sorting principle is in accordance with the geometric characteristics of the seed to determine the type and variety of different grains, choose to replace the different aperture specifications of the sieve, can meet the requirements of sorting and grading.