- Home

- Products

- Harvester

- Self-propelled Corn Harvester

- 4YZP-4A Self-propelled Corn Combine Harvester

4YZP-4A Self-propelled Corn Combine Harvester

Self-propelled corn harvester 4YZP-4A model, equipped with 96kW engine, has high efficiency of cob picking and peeling technology, and short body design to adapt to small and medium-sized plots. The new cab provides a comfortable operating environment, and the taller cob box and new rear view system enhance operational convenience and safety.

Important parameters

- Nominal power: 88~96KW

- Engine type: Vertical, in-line, water-cooled, four-stroke

- Number of working rows: 4

Previous slide

Next slide

parameters

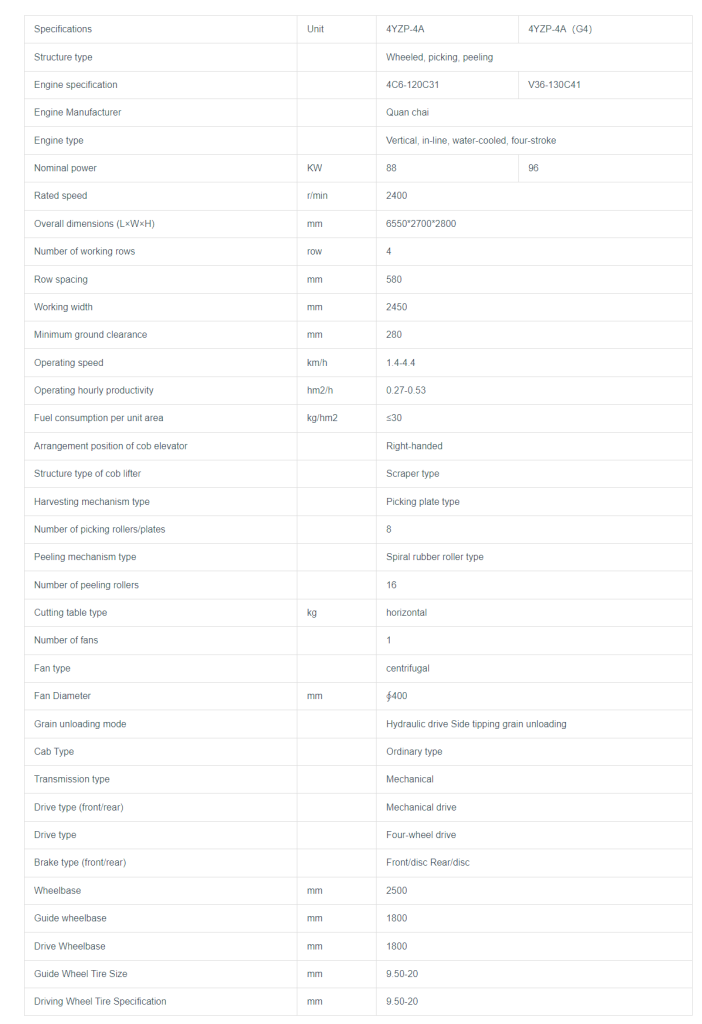

| Specifications | Unit | 4YZP-4A | 4YZP-4A(G4) |

| Structure type | Wheeled, picking, peeling | ||

| Engine specification | 4C6-120C31 | V36-130C41 | |

| Engine Manufacturer | Quan chai | ||

| Engine type | Vertical, in-line, water-cooled, four-stroke | ||

| Nominal power | KW | 88 | 96 |

| Rated speed | r/min | 2400 | |

| Overall dimensions (L×W×H) | mm | 6550*2700*2800 | |

| Number of working rows | row | 4 | |

| Row spacing | mm | 580 | |

| Working width | mm | 2450 | |

| Minimum ground clearance | mm | 280 | |

| Operating speed | km/h | 1.4-4.4 | |

| Operating hourly productivity | hm2/h | 0.27-0.53 | |

| Fuel consumption per unit area | kg/hm2 | ≤30 | |

| Arrangement position of cob elevator | Right-handed | ||

| Structure type of cob lifter | Scraper type | ||

| Harvesting mechanism type | Picking plate type | ||

| Number of picking rollers/plates | 8 | ||

| Peeling mechanism type | Spiral rubber roller type | ||

| Number of peeling rollers | 16 | ||

| Cutting table type | kg | horizontal | |

| Number of fans | 1 | ||

| Fan type | centrifugal | ||

| Fan Diameter | mm | ∮400 | |

| Grain unloading mode | Hydraulic drive Side tipping grain unloading | ||

| Cab Type | Ordinary type | ||

| Transmission type | Mechanical | ||

| Drive type (front/rear) | Mechanical drive | ||

| Drive type | Four-wheel drive | ||

| Brake type (front/rear) | Front/disc Rear/disc | ||

| Wheelbase | mm | 2500 | |

| Guide wheelbase | mm | 1800 | |

| Drive Wheelbase | mm | 1800 | |

| Guide Wheel Tire Size | mm | 9.50-20 | |

| Driving Wheel Tire Specification | mm | 9.50-20 | |

Features

- Cab design: Equipped with a new type of round-arc cab, providing beautiful appearance and wide vision, and equipped with adjustable steering column to ensure driving comfort and convenience.

- Engine performance: Equipped with 96kw high-horsepower engine to ensure strong power and sufficient reserve, optional National III engine to adapt to different emission standards.

- Power system: adopting two-way output engine, realizing separate operation of main power and traveling power, improving the convenience and reliability of operation.

- Clutch maneuvering device: mechanical main clutch maneuvering device, providing safe and reliable driving experience.

- Adaptability: High horsepower with short body design, especially suitable for the operational needs of small and medium-sized plots.

- Spike picking efficiency: The spike picking device adopts advanced stem pulling roller + spike picking plate structure, which reduces the loss of spikes and seeds and improves the efficiency of spike picking.

- Peeling technology: the peeler is equipped with double fans and four sets of sixteen rollers peeling device, rubber rollers + rubber roller structure, realizing high peeling clean rate and peeling efficiency and reducing seed loss.

- Grain unloading convenience: the height of cob box unloading is increased to adapt to the demand of high box transportation used by farmers.

- Enhanced passability: the working ladder on the driver’s platform adopts a rotatable structure to improve the passability of the machine.

- Heat dissipation performance: the new water tank shroud design effectively reduces the engine temperature and prolongs the engine life.

- Additional function: front chopping device can be added to improve operational diversity.

- Rear view system: equipped with a new rear view system, the cab can observe the working status of the peeler and realize visual reversing, reducing the occurrence of failures.