- Home

- Products

- Harvester

- Self-propelled Rice Combine Harvester

- 200HP Self-propelled Grain Combine Harvester 4LZ-9B(G4)

200HP Self-propelled Grain Combine Harvester 4LZ-9B(G4)

4LZ-8B1 is a self-propelled wheel type grain combine harvester, it adopts cutting flow + horizontal axial flow drum threshing separation technology, strong threshing power; Reasonable design structure, convenient maintenance and newly appreance design; Mainly harvest wheat, if replace parts, can harvest the rice,soybeans, rapeseed, corn seeds and so on.

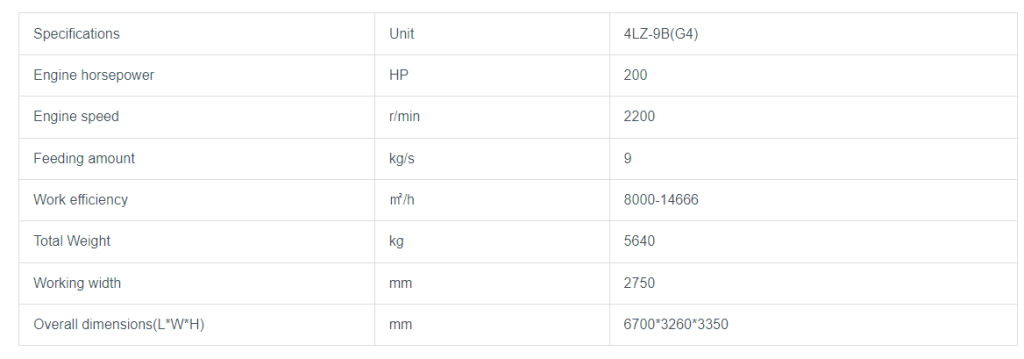

parameters

| Specifications | Unit | 4LZ-9B(G4) |

| Engine horsepower | HP | 200 |

| Engine speed | r/min | 2200 |

| Feeding amount | kg/s | 9 |

| Work efficiency | ㎡/h | 8000-14666 |

| Total Weight | kg | 5640 |

| Working width | mm | 2750 |

| Overall dimensions(L*W*H) | mm | 6700*3260*3350 |

Features

- The cuttingtable can be equipped with a quick-hook cutting table, which is more convenient and can be completed independently.

- An anti-grassentanglement device is added to the right side of the reel, which greatly reduces product maintenance time during operation and improves operation efficiency. :

- Using cutting flow + transverse axial flow drum threshing and separation technology,the threshing chamber is lengthened by 100 mm, the threshing speed is fast, and the materials are completely separated.

- The axial flow roller web is re-opened, and the separation plate and nail teeth are heat treated, The quality is more reliable and theworking intensity is greatly improved.

- The engine power is increased to 200 horsepower, and a multi-function switch is added, The horsepower can be changed between 125and 200 horsepower to meet more user needs; power output pulleyChanged from Φ248 to Φ272, the walking speed is increased by 10% and the operating efficiency is higher.

- The power output assembly belt, walking belt, and threshing drum belt all use red label belts to increase service life, reduce replacementcycles,and improve operating efficiency.

- The volume of the granary is increased to 2.7 cubic meters to reduce the number of grain unloading times. The diameter of the grain unloading cylinder is thickened to 275 mm for fast grain unloading speed. The length of the grain unloading cylinder is lengthened to 2.5meters and the grain unloading height reaches 3.4 meters. Unloading grain is more convenient and faster.

- Brand new arc cab, optional one-pole solenoid valve operation, and optional original air conditioner.

- Improve the hydraulic main clutch tensioning arm to increase strength, prevent deformation, and greatly extend product life.

- The chassis is made of 16Mn high-strength material, and the welding process is changed to improve the strength of the frame, greatlyextending the service life of the entire machine, and the value retention rate is higher.

- The intermediate shaft uses a 42CrMo solid shaftand is thickened, and the bearings are upgraded from 207 to 210, increasing the strength by 25% and improving the quality and reliability of the entire machine.