AT100 Self-Propelled Grain Combine Harvester 200HP

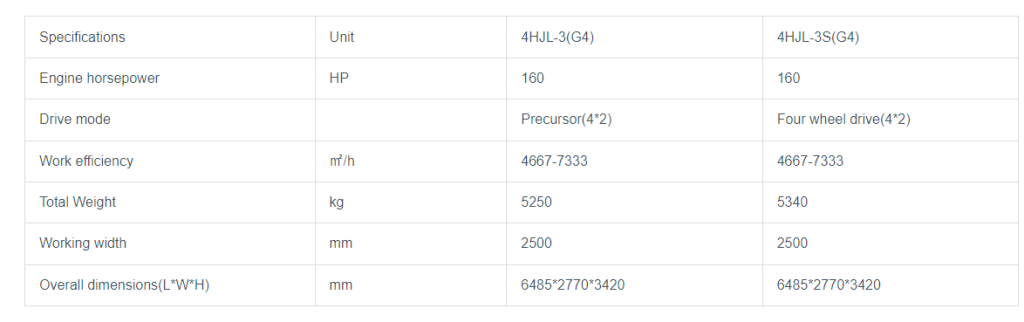

Home Products Harvester Self-propelled Rice Combine Harvester AT100 Self-Propelled Grain Combine Harvester 200HP AT100 Self-Propelled Grain Combine Harvester 200HP The AT100 self-propelled full-feed grain combine harvester adopts