The importance of agricultural machinery in modern agriculture cannot be overstated. With the increasing scale and mechanization of agricultural production, agricultural machinery has become an indispensable tool in farm operations, especially in large farms and efficient production environment, the efficiency of agricultural machinery directly affects the overall operating costs and output benefits of the farm. Especially in the current context of increasing fuel prices, how to improve the fuel efficiency of agricultural machinery has become the focus of attention of farmers and agricultural operators.

Fuel efficiency directly affects the operating costs and profitability of agricultural machinery. Especially for large farms, fuel consumption occupies a significant portion of production costs, and optimizing fuel use not only reduces economic pressure, but also contributes to environmental protection. This article will provide farmers with some practical tips on how to improve the fuel efficiency of their farm machinery, thereby reducing overall production costs and improving production efficiency.

Through this article, you will learn how to improve fuel efficiency through regular maintenance, proper operation and choosing the right model. In addition, there will be an in-depth look at some of the efficient fuel additives and intelligent control technologies that enhance fuel efficiency and help agricultural machinery achieve more efficient operations. In what follows, we will reveal these practical tips for improving fuel efficiency, ensuring that farmers can benefit from them and further optimize all aspects of agricultural production.

Contents

- 1 I. Regular Maintenance: Keeping Machinery Running Efficiently

- 1.1 1. Engine Maintenance: Ensuring a Clean and Efficient Power System

- 1.2 2. Hydraulic System Maintenance: Enhancing Operational Efficiency and Reducing Wear and Tear

- 1.3 3. Tire maintenance: prolong service life and reduce fuel consumption

- 1.4 4. Maintenance of other key components: details determine efficiency

- 1.5 5. Timely replacement of spare parts: Reduce equipment downtime

- 2 II. Correct operation: the influence of operating habits on fuel consumption

- 2.1 1. Smooth Driving: Reducing Unnecessary Fuel Waste

- 2.2 2. Reasonable arrangement of working time: avoiding operation in high temperature

- 2.3 3. Avoid unnecessary idling: Reduce ineffective fuel consumption

- 2.4 4. Optimizing operations in relation to the operating environment: Adjusting operations according to soil and environmental conditions

- 3 III. Choosing the right model: fuel-saving considerations at the purchase stage

- 4 IV. Use of high-efficiency fuel additives: improving fuel quality

- 5 V. Technology Upgrade: Intelligent Control and Precision Management

- 6 VI. Frequently Asked Questions and Solutions

- 7 Conclusion

I. Regular Maintenance: Keeping Machinery Running Efficiently

1. Engine Maintenance: Ensuring a Clean and Efficient Power System

Regular checking of the engine is the key to ensuring the continuous and efficient operation of agricultural machinery. The engine is the core component of agricultural machinery, and proper maintenance can effectively improve fuel efficiency and extend the service life of the equipment.

Check the oil and oil circuit system: change the oil regularly, check the oil circuit system for oil leakage or carbon deposits, and avoid oil impurities affecting engine performance. Using high-quality engine oil not only improves engine operating efficiency, but also reduces fuel consumption.

Clean the air filter and fuel filter: the air filter blocks dust and impurities to ensure that the engine inhales clean air; the fuel filter ensures a smooth fuel system to avoid clogging. Regularly cleaning or replacing filters reduces fuel consumption and improves engine stability.

Check the cooling system: Maintaining the proper operating temperature of the engine is essential for efficient operation. Regularly check the radiator, coolant and piping system to ensure that the cooling system is working properly and to avoid overheating of the engine leading to performance degradation.

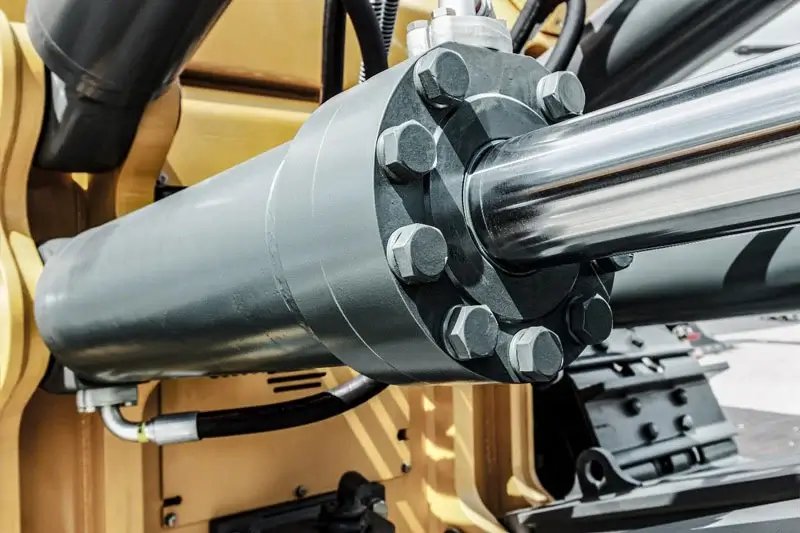

2. Hydraulic System Maintenance: Enhancing Operational Efficiency and Reducing Wear and Tear

The efficient operation of the hydraulic system is another important factor in the ability of agricultural machinery to work smoothly and efficiently. The hydraulic system plays a decisive role in the function and operation quality of agricultural machinery, so regular maintenance of the hydraulic system is particularly important.

Check the hydraulic oil and hydraulic pipeline: hydraulic oil is the core to ensure the efficient operation of the hydraulic system, we should regularly check the quality and level of the oil, to avoid the deterioration of the oil or insufficient oil to affect the operational efficiency. Hydraulic pipeline should be free of leakage, and regularly clean the impurities in the pipeline to avoid clogging or oil leakage.

Regular replacement of hydraulic oil: the quality of hydraulic oil directly affects the system performance and mechanical life. Choose the hydraulic oil that meets the requirements of the equipment and replace it according to the cycle recommended in the equipment manual.

Check the hydraulic pump and hydraulic cylinder: the sealing and working condition of the hydraulic pump and hydraulic cylinder directly affects the performance of the equipment, regularly check its working condition to ensure that there is no leakage, and timely repair and replacement of faulty parts.

3. Tire maintenance: prolong service life and reduce fuel consumption

Tires are the key parts of agricultural machinery in contact with the ground, good tire condition not only prolongs service life, but also effectively improves fuel efficiency and reduces unnecessary friction in operation.

Regularly check tire pressure: Tire pressure has an important impact on fuel consumption. Excessively high or low tire pressure will lead to increased mechanical load and unnecessary fuel waste. Regularly check the tire pressure according to the use of the equipment and the environment to ensure that the tires are in the best working condition.

Check tire wear: Uneven tire wear or aging can affect vehicle stability and operating results. Regularly check tire wear and adjust or replace tires according to the degree of wear to avoid a decline in operating efficiency caused by excessive tire wear.

Choose the right type of tires: Different operating environments have different requirements for tires, and choosing the right type of tires (e.g., mud tires, grass tires, etc.) will help to improve traction of the tractor, reduce the slip rate, and lower fuel consumption.

4. Maintenance of other key components: details determine efficiency

In addition to the engine, hydraulic system and tires, other components in agricultural machinery also require regular inspection and maintenance to ensure efficient operation of the equipment.

Check the brake system: The proper functioning of the brake system is crucial to the safety and operational efficiency of agricultural machinery. Regularly check the fluid level of the brake system, brake pad wear, and timely adjustment or replacement to ensure safe operation.

Lubrication system check: There are many moving parts in agricultural machinery, regular check and add lubricant to reduce friction and wear and tear, prolong the service life of the machinery, and ensure the smooth operation of the equipment.

Electrical system check: the normal operation of the battery and electrical system is to ensure that the agricultural machinery start and efficient operation of the basis. Regularly check the battery voltage and circuit system to ensure that the equipment can start stably in various environments.

5. Timely replacement of spare parts: Reduce equipment downtime

Wear and tear and aging of spare parts are common problems of agricultural machinery. Timely replacement of aging or damaged parts not only extends the life of the machinery, but also avoids downtime due to equipment failure, ensuring the smooth running of agricultural operations.

Timely replacement of oil filters, air filters: these wear parts will be used with the increase in time, and gradually lose filtering capacity, affecting the operating efficiency of the engine. Regular replacement of these parts can ensure efficient engine operation and reduce fuel consumption.

Pay attention to tires and transmission parts: tires and transmission parts are easy to be worn out during long time operation, regular inspection and replacement of these parts can avoid equipment downtime and additional maintenance costs due to failure.

II. Correct operation: the influence of operating habits on fuel consumption

1. Smooth Driving: Reducing Unnecessary Fuel Waste

Smooth driving can not only prolong the service life of agricultural machinery, but also effectively reduce fuel consumption. Rapid acceleration, harsh braking and other operating habits will significantly increase fuel consumption and lead to unnecessary waste of resources. Good operating habits are essential to improve fuel efficiency.

Avoid rapid acceleration and harsh braking:

Avoid sudden acceleration and harsh braking when driving agricultural machinery. When accelerating quickly, the engine consumes more fuel, while hard braking reduces the efficiency of the braking system and increases the burden on the machinery. By driving smoothly, farmers not only improve fuel efficiency, but also reduce mechanical wear and tear on their equipment.

Adjusting Speed to the Operational Load:

Different agricultural operations (e.g., plowing, seeding, or harvesting) require different speeds. Selecting the right operating speed for the specific load during operation not only saves fuel but also improves operational efficiency. For example, it is not necessary to maintain a high speed under light loads, while increasing power and speed appropriately to maintain smooth operation during heavy loads.

2. Reasonable arrangement of working time: avoiding operation in high temperature

Reasonable arrangement of working time can not only improve working efficiency, but also effectively avoid the negative impact on mechanical performance in high temperature. In the summer and other hot periods, excessive operation of machinery is not only inefficient, fuel consumption will also increase significantly.

Choose to work in the morning or evening:

During the cooler periods of the day (morning or evening), high load operations can effectively avoid overloading the engine at high temperatures, which not only helps to improve fuel efficiency, but also reduces the risk of overheating the machinery and prolongs the service life of the equipment. Farmers should make reasonable arrangements according to the weather forecast.

Avoid operating in the midday heat:

Midday is usually the hottest time of the day, and engine operation at this time may lead to higher fuel consumption and more wear and tear on equipment. Therefore, try to avoid high intensity operations during the midday hours. 3.

3. Avoid unnecessary idling: Reduce ineffective fuel consumption

Idling not only wastes fuel, but also increases wear and tear on mechanical parts. Prolonged idling is not only ineffective in terms of fuel consumption, but also leads to an increase in fuel consumption and a decrease in the efficiency of the engine.

Reasonable control of idling time:

Avoid idling of farm machinery when it is not needed for work, especially after it stops working, if there is no immediate task that needs to be used, the engine can be turned off to avoid unnecessary waste of fuel.

Set a reasonable working schedule:

To avoid ineffective idling, the working and resting time of the equipment should be reasonably planned according to the actual operational needs of the farm, so as to reduce the fuel waste caused by idling of the equipment. Modern agricultural machinery is often equipped with automated systems that can adjust the working and standby time of the machine according to the task demand, and farmers can make use of these intelligent systems to reduce idling.

4. Optimizing operations in relation to the operating environment: Adjusting operations according to soil and environmental conditions

Every piece of farmland has different soil types, crop varieties and environmental conditions, which directly affect the workload and fuel consumption of machinery. Adjusting the operation to the operating environment can lead to better fuel savings.

Adjust the operating depth and speed according to the soil type:

When working in hard soil, increase the operating depth and reduce the operating speed appropriately in order to avoid overloading the machinery and resulting in fuel wastage; while in soft soil, you can speed up the operating speed appropriately to reduce unnecessary fuel consumption.

Choose suitable farm machinery configuration:

Different operational tasks (such as seeding, fertilizing, harvesting) should choose different configurations of farm machinery. For example, in dry areas or places with low crop growth density, using low-power or small farm machinery can reduce fuel consumption.

III. Choosing the right model: fuel-saving considerations at the purchase stage

1. Selecting the right model for the size of the farm and operational needs

When purchasing agricultural machinery, selecting the right model is the first step in improving fuel efficiency. Different operating environments and farm sizes have different needs for machinery performance, so choosing the right model can minimize fuel waste.

Choose a model according to the type of operation and workload:

For small farms or low-intensity operations, choosing a suitable low-power model can avoid fuel wastage due to over-configuration. Higher-power models are more capable, but will consume too much fuel if used only for light-duty work.

For large farms or intensive operations, choose a model with high efficiency and power to not only improve efficiency, but also to ensure more effective fuel utilization during long periods of high workloads.

Choose an adaptable model:

Choose a model that can adapt to different operating environments (e.g. hills, plains, wetlands, etc.). The adaptability of an agricultural machine is directly related to the terrain, and a model that is not adaptable will increase the workload and lead to lower fuel efficiency. For example, tire configuration, body height and other factors will affect the fuel consumption of the tractor in a particular environment.

2. Power and load matching: Ensure that power requirements are matched to the work load

Selecting a suitable model that matches power and load is key to reducing fuel consumption. When selecting a farm machine, make sure its power matches the farm’s operating load to avoid increased fuel consumption due to under- or over-loading.

Avoid low loads:

Higher-powered models at low loads consume more fuel than models at moderate loads. Select a model that is suitable for the load to avoid wasting energy due to under- or over-performance of the machine.

Fuel consumption and engine efficiency are affected when machinery is operated at low loads, so try to avoid ineffective low load operation.

Adjust model selection to operational needs:

Select models with different speed regulation features for the needs of different farm crops. For example, for plowing, a higher power output is needed, while for planting and fertilizing, a lower power model can be chosen to save fuel.

IV. Use of high-efficiency fuel additives: improving fuel quality

The use of high-efficiency fuel additives can improve fuel quality, reduce carbon deposits and improve combustion efficiency, thus effectively reducing fuel consumption and increasing the working efficiency of agricultural machinery.

Choose the right fuel additives:

introduces common agricultural fuel additives in the market, including detergents, antioxidants and efficient combustion enhancers, etc. These additives can help clean the fuel system, improve fuel combustion efficiency and reduce fuel waste.

Using the right additives can improve complete combustion, reduce unburned fuel emissions, reduce the environmental impact of exhaust fumes and help save fuel.

Regular use of additives:

Regular use of fuel additives helps to keep the fuel system clean and avoid incomplete combustion due to degradation of fuel quality during long-term use. Regular use can effectively reduce mechanical failures and improve engine efficiency.

V. Technology Upgrade: Intelligent Control and Precision Management

As agricultural machinery technology continues to advance, more and more farm equipment is adopting intelligent control systems, which not only improve operational convenience, but also accurately regulate operating parameters to help farmers optimize fuel use efficiency.

Intelligent control systems:

Modern tractors and other agricultural machinery are equipped with intelligent control systems (e.g., GPS navigation, autonomous driving, precision agriculture technology) that can automatically adjust the operating depth, sowing density, speed, etc., so as to optimize fuel consumption.

For example, GPS navigation systems can optimize work paths and reduce unnecessary repetitive work and detours, thus saving fuel and improving work efficiency.

Precision Agriculture and Automation Management:

Precision agriculture technology helps farmers precisely control each operation through data analysis and sensor technology, reducing manual intervention and improving the intelligence of agricultural production.

The automated management system monitors the fuel consumption of farm machinery and automatically adjusts the parameters of the equipment according to the actual operating conditions to maximize fuel efficiency.

VI. Frequently Asked Questions and Solutions

Why does my tractor consume too much fuel?

Provide specific troubleshooting steps, such as checking the engine, hydraulic system, tire pressure, etc., to help farmers find out why fuel consumption is too high.

How to reduce fuel waste during low-load operations?

Provide strategies to optimize operation and model selection to avoid fuel waste during low load operation.

How can I tell if my farm machinery needs maintenance?

Provide some warning signals of fuel efficiency degradation, such as engine shaking, hydraulic system failure, etc., to help users find the problem and deal with it in time.

Conclusion

This paper summarizes practical tips to improve the fuel efficiency of agricultural machinery, emphasizing important measures such as regular maintenance, correct operation, and selection of suitable models. Through scientific machinery maintenance and reasonable operating habits, farmers can effectively reduce fuel consumption and operating costs, thereby improving productivity and equipment life.

At the same time, choosing the right model and using efficient fuel additives will further improve fuel combustion efficiency and promote the green development of agricultural machinery. The application of intelligent control systems also provides strong support for precision agriculture, helping farmers realize more efficient and environmentally friendly agricultural production.

In order to help farmers better implement these techniques, the MINNUO brand offers a variety of highly efficient and intelligent agricultural machinery, with advanced intelligent systems and energy-saving technology, helping farmers to maximize fuel cost savings while ensuring efficient operations.MINNUO is committed to providing advanced agricultural equipment and quality after-sales service to farms around the world, and helping the agricultural industry to achieve sustainable development.