Is your harvester running slow during peak harvest? Experiencing excessive grain loss or frequent breakdowns? The root causes often lie hidden within its core components. While combine harvesters are indispensable for high-efficiency harvesting, their true performance is not defined by their size or appearance—but by the strength of their internal systems.

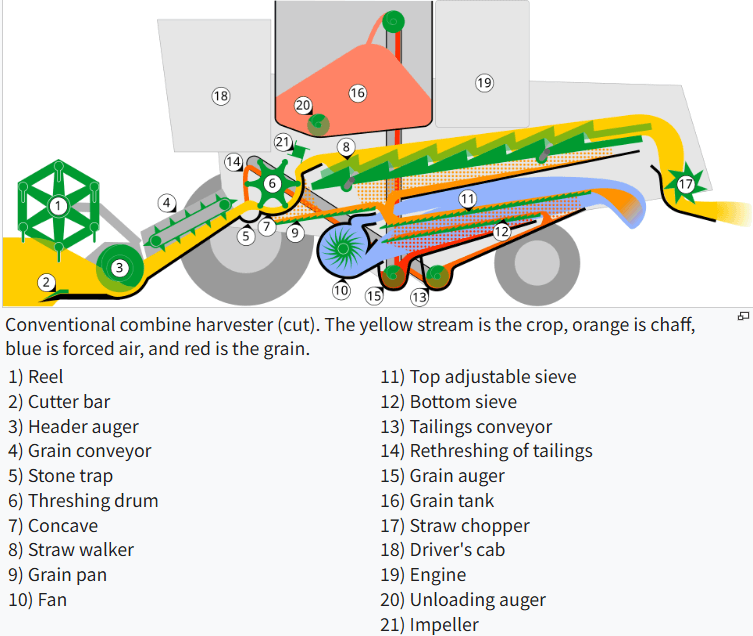

A modern combine harvester operates through eight major coordinated systems: the cutting system, feeding system, threshing system, cleaning system, grain tank and unloading system, power and transmission system, chassis and mobility system, and the intelligent control and safety protection system. Each plays a critical role—remove any one, and the whole operation can fail.

In this article, we’ll walk you through each of these critical systems, breaking down what makes a harvester effective—and how to choose the right one for your needs.

Contents

- 1 I. What is a Combine Harvester?

- 2 II. Cutting System: The Harvester’s First Point of Contact

- 3 III. Feeding & Conveying System: Preventing Crop Blockages

- 4 IV. Threshing System: Separating Grain from Straw

- 5 V. Cleaning System: Ensuring Clean Grain Output

- 6 VI. Grain Tank & Unloading System: Supporting Continuous Work

- 7 VII. Power & Transmission System

- 8 VIII. Chassis & Mobility System

- 9 IX. Control & Smart System

- 10 X. Safety & Protection System

- 11 XI. Maintenance & Lubrication System

- 12 XII. Conclusion

I. What is a Combine Harvester?

A combine harvester is a multi-functional agricultural machine that integrates cutting, threshing, cleaning, and grain collection into one continuous process. It replaces the traditional segmented method of manual harvesting followed by mechanical threshing.

Its key advantages include:

Significantly improved harvesting efficiency (a large machine can process 100–300 acres per day),

Lower grain loss rates, and

Reduced labor dependency.

For large-scale farming operations, it is a core piece of equipment that drives both productivity and profitability.

II. Cutting System: The Harvester’s First Point of Contact

The cutting system is the “frontline tool” of the combine harvester. Its performance directly impacts the efficiency of every downstream system.

1. Cutter Header (Cutting Unit)

The cutter header is the core of the cutting system, and its design varies based on crop type. Key design elements determine both crop adaptability and cutting quality.

(1) Types of Headers & Their Applications:

| Header Type | Suitable Crops | Key Design Features |

| Grain Header | Wheat, Rice, Barley | Wide cutting width (1.5–6m), sharp blades |

| Corn Header | Corn | Equipped with snapping rollers, ear conveyors |

| Rapeseed Header | Rapeseed | Low stubble cutting, anti-scatter deflectors |

| Forage Header | Silage Corn, Alfalfa | Integrated shredding, high feed efficiency |

(2) Key Components:

Reel: Positioned at the front to guide fallen or scattered crops into the cutter.

Cutter Bar: Comprises moving and fixed blades and guards; completes cutting via reciprocating motion.

Auger Conveyor: Gathers cut crops to the center and forwards them to the feeding system.

(3) Technological Upgrades for Complex Fields:

Advanced headers like those in Minnuo Combine Harvesters feature:

Hydraulic variable-speed reel (20–60r/min), adjustable for different crop densities (e.g., faster for dense wheat, slower for sparse corn).

Floating cutter bars with tungsten carbide blades, maintaining cutting error within ±0.5cm on slopes ≤15°, with a 2.3% lower grain loss rate than industry average. Ideal for terraced fields in southern China and hilly areas in the northeast.

2. Header Height & Angle Adjustment Mechanism

Auto Adjustment: Uses infrared sensors to detect crop height and terrain, keeping stubble height between 5–15cm.

Manual Adjustment: Allows fine-tuning in uneven or lodged crop fields to ensure continuous and effective harvesting.

III. Feeding & Conveying System: Preventing Crop Blockages

If the harvested crop can’t be fed smoothly, it clogs. The feeding and conveying system ensures a steady, uniform crop flow into the threshing system.

1. Feeding Auger & Conveyor Chains

Structure & Materials: Chains use wear-resistant alloy steel (≥800MPa tensile strength); auger blades are heat-treated (HRC50+) for durability.

Function: The auger centralizes the crop and feeds it steadily (0.8–1.5m/s) into the threshing chamber.

2. Feed Rate Regulator

Controls throughput to balance speed and prevent system overload:

Principle: Sensors detect crop flow, adjusting forward speed or chain speed when overload is detected.

Benefit: Keeps feed rate fluctuation within ±10%, improving both efficiency and reliability.

3. Anti-Clogging System

Mechanism: Reverse auger ejects crop during clogging; elastic baffles adjust to crop density.

Alarms: When pressure exceeds set thresholds (e.g., ≥500N), visual and audible alerts notify the operator of blockage location

IV. Threshing System: Separating Grain from Straw

This system uses mechanical force to remove grains from the crop heads, directly affecting grain recovery rate.

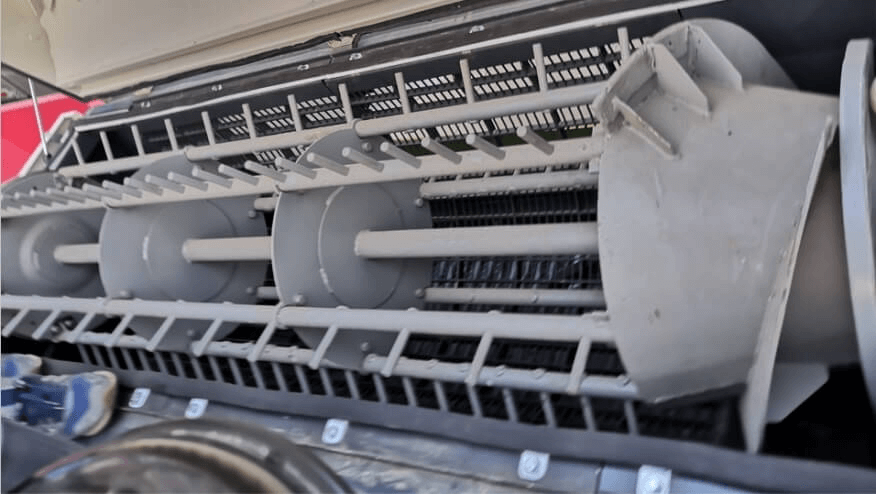

1. Threshing Rotor

Types:

| Rotor Type | Structure | Suitable Crops | Advantage |

| Cylindrical Drum | Equipped with teeth/bars | Wheat, Rice | Simple, easy maintenance |

| Axial-Flow Rotor | Spiral teeth, large length/diameter ratio | Corn, Soybean | Thorough separation (≥98%), low damage |

Speed Range: Adjustable 500–1200r/min. Choose high-speed for small grains (wheat, rice), low-speed for large grains (corn, soybean) to avoid damage.

2. Concave Screen

Gap Adjustment: 5–30mm via hydraulics; fine gap for small grains (5–10mm), wide for large grains (15–30mm).

Durability: Made of cast iron or manganese steel; >2000h lifespan.

3. Straw Conveyor

Handles post-threshing straw and recovers residual grain:

Types: Oscillating (shakes off grains) or Conveyor (with scraper chains).

Function: Ensures residual grains are sent back for cleaning, improving recovery by 1–2%.

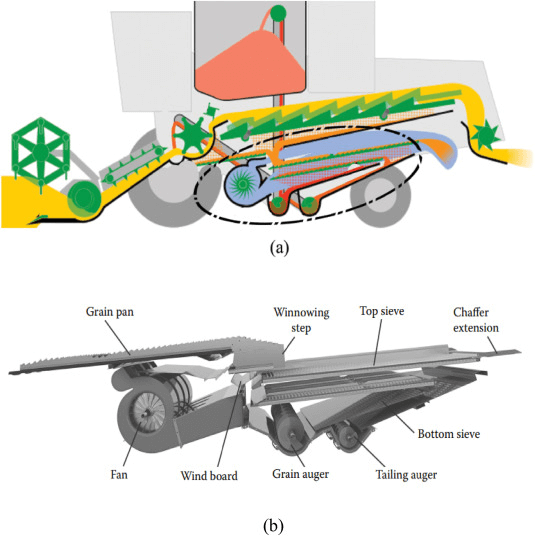

V. Cleaning System: Ensuring Clean Grain Output

Post-threshing grain contains husks, straw fragments, and debris. This system purifies the yield before storage.

1. Cleaning Fan

Airflow Control: 1000–2000r/min; higher for wet crops (>20% moisture) to ensure separation without grain loss.

Smart Adjustment: Variable-speed fans auto-adjust based on impurity levels—removal efficiency ≥95%.

2. Sieve System

Upper Sieve: Larger holes (8–12mm) remove husks.

Lower Sieve: Smaller holes (3–6mm) separate heavy impurities.

Adjustability: Frequency (300–500 rpm) and angle (5–15°) can be tuned for crop type and grain size.

3. Grain Tray & Return Auger

Grain Tray: Collects cleaned grain and feeds it to the grain elevator.

Return Auger: Recycles partially cleaned grain for reprocessing—final purity ≥98%.

VI. Grain Tank & Unloading System: Supporting Continuous Work

1. Grain Tank

Capacity: Ranges from 2–6m³. Must match harvesting efficiency (e.g., 3m³ for 5 acres/hr).

Material: Lightweight aluminum alloy or fiberglass with smooth lining to avoid residue.

Level Sensor: Ultrasonic sensor triggers an alarm when 80% full.

2. Unloading Auger (Grain Elevator)

Structure: Vertical and horizontal screw conveyors (3–6m total length).

Output: 30–60 tons/hour; height range 2.5–4m.

Control: Operable from cabin or remote. Remote unloading saves 1–2 minutes per batch.

VII. Power & Transmission System

The engine supplies energy, while the transmission system distributes it—their synergy dictates power performance and fuel efficiency.

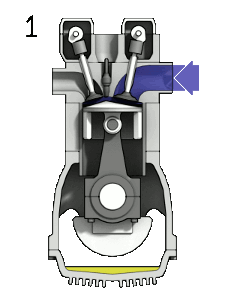

1. Engine

Type & Power: 4-stroke water-cooled diesel (50–300 HP).

Flatlands: 100–150 HP

Hills: 80–120 HP

Large farms: 200–300 HP

Power Allocation: Dynamically distributed via ECU:

Walking: 40%

Cutting: 25%

Threshing: 20%

Cleaning: 15%

Emissions: Meets China Stage III or higher; exports meet Euro IV / Tier 4.

2. Transmission Types

| Type | Structure | Advantage | Application |

| Mechanical | Gears, clutch, shafts | Low cost, easy maintenance | Small (<100 HP) |

| Hydraulic | Pumps, cylinders, motors | Smooth speed change | Medium (100–200 HP) |

| Hydrostatic | Variable pump + fixed motor | Stepless, fast response | Large (≥200 HP) |

Differential & Final Drive: Enhance cornering and hill-climbing.

3. PTO (Power Take-Off)

Function: Drives headers, conveyors, etc., at 540–1000r/min.

Safety: Overload clutch disengages under blockage to prevent damage.

VIII. Chassis & Mobility System

Determines the machine’s field adaptability and maneuverability.

1. Frame

Material: Welded Q345 steel (8–12mm thick).

Shock Absorption: Rubber dampers (0.3–0.5 damping factor) reduce vibration.

2. Mobility (Wheels vs Tracks)

| Type | Terrain | Pros | Cons |

| Wheeled | Plains, dryland | Fast (15–25 km/h), agile | High soil compaction |

| Tracked | Mud, hills | Low pressure, better mobility | Slower, costlier to maintain |

Tires: High-floatation radial tires (300–500mm wide) reduce soil compaction by 30%.

Suspension: Hydraulic suspension on larger models adjusts height for ridges.

3. Steering

Hydraulic Power Steering: Reduces effort to 5–10N.

Four-Wheel Steering: Tightens turning radius by 20–30%—ideal for narrow-row fields.

IX. Control & Smart System

Enhances precision, ease of use, and data-based decision-making.

1. Operator Cabin

Ergonomics: Multi-adjustable seat with suspension; comfortable for 8–10h/day.

Visibility: Panoramic windows (≥120° view), 2–4 cameras.

Environment: Standard air-con (16–30°C) and dust filters.

2. Control Panel

Display: 5–10″ color touchscreen shows real-time data (engine RPM, grain moisture, throughput, area covered).

Controls: Multi-function joystick integrates key operations.

3. Smart Technologies

GPS / BeiDou Navigation: Dual-mode, <2cm accuracy, reduces overlap from 5–8% to 1–2%.

Yield Mapping: Visualizes field productivity by area for better future planning.

Remote Diagnostics: 4G/5G connected backend sends fault alerts and solutions.

Auto Parameter Adjustment: Minnuo models auto-adjust rotor speed, airflow, sieve vibration, and support mobile app monitoring. Fault detection accuracy ≥92%, reducing downtime by 3 hours/day.

X. Safety & Protection System

Ensures operator safety and equipment reliability in harsh field conditions.

1. Safety Guards

Rotating Parts: Protected by 2mm steel covers with ≤5mm clearance.

Emergency Stops: Located in cabin and on both sides; power cuts within 1 second.

Interlocks: Open guards = auto shutdown.

2. Fire Protection

Extinguishers: ≥2kg dry powder near engine and fuel tank; check pressure regularly.

Temperature Sensors: Alerts if exhaust >800°C or hydraulic oil >80°C.

3. Lighting & Signals

LED Work Lights: ≥10,000lm, for early morning/night operation.

Warning Lights: Turn, brake, and fault indicators with sound alarms.

XI. Maintenance & Lubrication System

Routine maintenance is key to long life and fewer failures.

1. Lubrication

Types:

Central: Auto oiling for key parts (e.g., rotor bearings) every 30 mins.

Manual: Grease fittings on minor parts.

Oil Types:

Summer: Hydraulic Oil #46

Winter: Hydraulic Oil #32

Gearboxes: 85W-90 heavy-duty gear oil (replace every 500 hrs)

2. Service Access

Easy Access Doors: Hydraulic-assisted panels on threshing/cleaning systems.

Quick-Change Parts: Tool-free designs (e.g., Minnuo cutter blade changes in 5–10 minutes with a wrench).

3. Maintenance Schedule:

| Interval | Key Tasks | Criteria |

| Daily | Check fuel, hydraulic, coolant; clean sieves | Fluid ≥1/4 mark; no residue |

| Weekly | Chain tension, grease points | Chain sag ≤20mm; grease overflow |

| Monthly | Tire pressure, air filter | 2.5–3.0 bar; replace if clogged |

| Annually | Oil changes, frame weld inspection | Replace dirty oil; no cracks |

XII. Conclusion

Though each of the eight systems may seem independent, a combine harvester’s performance relies on seamless coordination: precise cutting, smooth feeding, efficient threshing, clean grain separation, secure storage—supported by strong power, smart control, and solid protection.

If you’re frustrated with low efficiency, high grain loss, or time-consuming maintenance, it’s worth exploring Minnuo Combine Harvesters. With tungsten carbide headers, crop-adaptive smart systems, and easy-maintenance designs, every part is engineered to solve real harvesting problems.

Wondering how Minnuo combine harvesters can adapt to your field or crop? Contact us today for a personalized equipment recommendation.