In the context of high-intensity operation of agricultural machinery, tractor key components in the event of sudden failure, not only means that the equipment downtime, but also may lead to the loss of farm time, maintenance costs surge, and even lead to potential safety hazards. Especially in the busy season, a small drive shaft breakage or hydraulic system leakage, may evolve into tons of economic losses. This article focuses on the core, is how to “seem normal” in the use of the process, as early as possible to identify these hidden wear and tear.

Many users are concerned with the question: How do I know which parts are going bad? Do I have to wait until the “sound changes” or “hard starting” to recognize a failure? Once these problems have already occurred, it is already too late. This article provides insights into visual inspections, monitoring with data, common signs of wear and tear, and how to make judgments based on actual operating conditions, so that you can truly achieve “predictive maintenance” instead of “reactive repair”.

Read on to learn how to recognize the early signs of wear on common tractor parts, and how to combine MINNUO’s solutions to create a more rational maintenance rhythm. Whether you are a farmer, a member of a cooperative, or an agricultural machinery repairer, this article will provide you with a practical and timely reference guide.

Contents

- 1 1. Tractor parts most prone to wear and tear

- 2 2. Early Warning Signs: What to Look, Listen, and Feel For

- 2.1 2.1 Visual inspection: the most easily ignored, but also the most worthwhile preventive measures

- 2.2 2.2 Sound identification: the tractor’s “language” can not be ignored

- 2.3 2.3 Tactile and Driving Experience: Driving “awkwardly” is usually a sign of a problem.

- 2.4 2.4 Instrumentation and sensor data: numbers do not lie, abnormalities are often well documented

- 3 3. Diagnostic Tools and Maintenance Techniques

- 4 4.Case Study: Early Detection That Prevented a Major Breakdown

- 5 5. Proactive Parts Replacement Strategy

- 6 6. How MINNUO Supports Predictive Maintenance

- 7 Conclusion

1. Tractor parts most prone to wear and tear

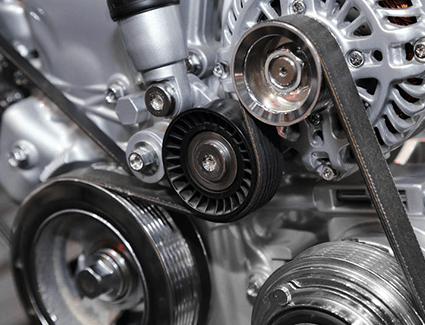

1.1 Engine belts and hoses

Frequently asked questions: Prolonged exposure to high temperatures and vibration can lead to deterioration, cracking and loosening.

Effects: Reduced engine efficiency, risk of overheating or unplanned engine stops.

Solution: Perform regular visual inspections every 250-500 hours to maintain proper belt tension and replace worn or damaged hoses and belts promptly.

1.2 Hydraulic hoses and seals

Frequently asked questions: Leaks, swelling, hardening or cracking due to pressure fluctuations, oil contamination and harsh working conditions.

Impact: Reduced hydraulic accuracy, loss of machine control and risk of equipment downtime.

Solution: Keep hydraulic fluid clean, inspect hoses and seals every 250-500 hours, and replace any parts showing signs of wear or leakage.

1.3 Brake Pads and Shoes

Common Problems: Worn friction material, unusual noise, and loss of braking power over time.

Impact: Reduced safety, especially when transporting heavy loads or working on sloping terrain.

Solution: Check the thickness of brake wear every 250-500 hours, adjust the gap if necessary, and replace the linings and shoes when they reach their limits.

1.4 Clutch system

Frequently asked questions: Wear of the friction plate and related parts leads to slippage, increased pedal force or poor engagement.

Impact: Reduced power transmission efficiency and increased risk of damage to the transmission system.

Solution: Regularly adjust the clutch gap, check the friction plates and pressure components, and replace them when there are signs of slippage or other wear.

1.5 Bearings and bushings

Frequently asked questions: Abnormal noise, vibration or increased temperature caused by wear, misalignment or insufficient lubrication.

Effects: Reduced accuracy, risk of damage to adjacent components, and potential equipment failure.

Solution: Maintain a lubrication program, inspect bearings every 250-500 hours, and replace when excessive clearance or noise is detected.

1.6 PTO Shafts and Universal Joints

Common Problem: Wear, inadequate lubrication, or misalignment results in excessive clearance, sticking, or noise.

Impact: Reduces the efficiency of the attached implements and increases the risk of mechanical failure.

Solution: Lubricate every 100-250 hours, check joints and splines for wear, and replace any parts with excessive clearance or sticking.

2. Early Warning Signs: What to Look, Listen, and Feel For

Tractor failure will often release some “signals”, as long as you pay attention to observation and perception, you can do early warning, early treatment. This section will be from the visual, auditory, tactile and instrument data in four aspects, to help you establish a set of simple and practical judgment system.

2.1 Visual inspection: the most easily ignored, but also the most worthwhile preventive measures

Many hidden dangers can be detected by the naked eye, but are often overlooked because they “still seem to work”:

Oil stains accumulation: oil stains around the engine, hydraulic system or brake system usually mean that the seals or pipelines are loosened or aged, and must be dealt with as soon as possible.

Cracked / loose rubber parts: belts, lines, etc., if the slightest crack or deformation, that is close to the limit of use, should be replaced in a timely manner.

Corrosion and rust spots: connectors, metal casing, if corrosion, may affect the strength, especially in the humid or fertilizer environment to be particularly vigilant.

Color change: lubricating oil blackened or emulsified, hydraulic oil discoloration, often the signal of increased internal wear or water pollution.

Suggestion: Make a habit of looking around and checking 5 minutes before each operation, paying special attention to the engine compartment, under the fuel tank, joint interface and other easy leakage points.

2.2 Sound identification: the tractor’s “language” can not be ignored

Before the machine out of the problem, the first change is often the sound.

Metal knocking sound: may be bearing wear, piston impact, loose transmission parts

Sharp friction sound: belt slack or brake system abnormalities, need to be checked immediately

Abnormal speed whirring: fan, hydraulic pump overload or jam

Suggestions: Turn off the cab sound, start a few minutes of no-loading before operation, and listen to whether there is an abnormal murmur.

2.3 Tactile and Driving Experience: Driving “awkwardly” is usually a sign of a problem.

Many abnormalities in operation can be “felt” by the body earlier than the eyes.

Increased steering wheel/seat shake: tire imbalance, drive shaft wear, or chassis loosening

Shifting is not smooth/hard to put into gear: clutch or transmission aging or need lubrication

Brakes become soft/latent: brake pads worn out, air intake in the fuel line, or aging brake fluid

Practical tips: Familiarize yourself with your machine’s “daily feeling” .When the feel and feel of your machine becomes “off”, don’t get used to it, check the cause.

2.4 Instrumentation and sensor data: numbers do not lie, abnormalities are often well documented

Modern tractors are increasingly equipped with basic sensors, but many users are accustomed to ignoring these data.

Water temperature is too high: clogged water tank, insufficient coolant or water pump failure

Oil pressure is too low: insufficient lubricant or pump wear, which may jeopardize the life of the engine

Abnormal battery voltage: generator failure or aging of the battery, which affects the starting performance

Speed alarm/load alarm: suggests that the drive system is overloaded and may be overheated or worn out accelerated

Suggestion: Record the core data (e.g. RPM, oil pressure, water temperature) before and after each operation to detect any trend of deviation.

3. Diagnostic Tools and Maintenance Techniques

Timely detection of problems and taking effective measures cannot be separated from scientific inspection methods and reasonable maintenance rhythm. This section combines traditional experience and modern tools, from manual testing, digital assistance, maintenance rhythm, data recording, to build a set of systematic diagnosis and maintenance strategy.

3.1 Commonly used manual inspection method: anticipating problems in “hands-on”

In rural or remote operation sites, when there is a lack of specialized instruments, experience and hands are the most reliable diagnostic means. Mastering the following basic operations, you can find hidden problems without instruments:

Looseness test: wrench key parts, such as steering tie rods, hydraulic joints, bolts, belts, etc., whether to shake, the feeling of looseness means the need to tighten or replace.

Friction and shaking perception: light pressure on the bearing position, if there is a strange sound or rustling feeling, it means that the internal wear and tear increased.

Visual Comparison: Compare the wear status of the left and right tires, tracks, and brake pads to determine whether there is an imbalance or failure on one side.

Tip: Set up a “5-minute unarmed inspection process” before the routine maintenance or operation of the tractor, which can warn more than 90% of common problems with only three steps of hand touching, foot stepping and eye seeing.

3.2 Digital Tools: The Key to Improving Diagnostic Efficiency

Modern agricultural equipment is becoming more and more “intelligent”, but many users only use 10% of the functions. Reasonable use of the following digital tools, not only faster to find problems, but also help maintenance decision-making:

infrared temperature gun: can detect the engine block, hydraulic pumps, motors, etc. whether the local overheating, is to identify the internal jamming or lubrication is not enough of an important tool.

Oil analysis tools: extract engine or hydraulic oil samples, through a simple analyzer or sent to the inspection, to assess the oil aging, metal particles content, can determine the degree of internal wear.

On-Board Electronic Diagnostic (OBD): Some medium and large tractors are equipped with OBD interface, which can read fault codes, such as abnormal air intake, high water temperature, and electronic control system failure, through cell phone APP or special terminals, which greatly improves the efficiency of overhaul.

Field case: a user found that the rear axle continued to overheat using infrared temperature measurement, and the inspection found that the gearbox was out of oil, and it only took 10 minutes to avoid the loss of overhaul.

3.3 Suggestions for the formulation of periodic maintenance schedule: let the maintenance no longer “by feeling”

Maintenance can not be “ad hoc”, but based on the workload of the equipment and seasonal characteristics, to develop a set of scientific rhythms.

| Recommended Maintenance Items | Recommended Cycles (hours) | Seasonal recommendations |

| Oil Change | Every 100-150 hours | May be shortened in summer |

| Hydraulic Fluid Check | Every 50 hours | Be sure to check thoroughly before winter |

| Air Filter Change | Every 200 hours or more frequently in heavily dusty environments | |

| Brake Check | Monthly or every 100 hours | |

| Battery Test | Before and after seasonal changes or storage |

Suggestion: Build a simple “maintenance form” for each machine, paper or Excel can be recorded, both easy to implement, but also easy to use for handover.

4.Case Study: Early Detection That Prevented a Major Breakdown

In farming, early detection = avoiding major losses. Below is a case study from an actual farm that illustrates how a common pre-season inspection avoided the double risk of costly repairs and delayed farm time.

4.1 Scenario background: a routine pre-seeding inspection

Before spring planting, a medium-sized farm in a certain area performed pre-season maintenance on its main tractor. During the inspection of the clutch disengagement mechanism, the maintenance personnel noticed that:

The pedal feedback was not smooth, and there was a “jerky feeling”.

There was a slight metallic friction sound when listening to the diagnosis.

After disassembling and inspecting, it was found that the inner ring of the clutch pressure plate had already shown signs of crack expansion.

Although the equipment was still usable, according to the judgment based on experience, it was very likely that the clutch would fail or seize during the peak planting period if it continued to be put into high-intensity operation. Although the equipment can still be used, according to experience, if it continues to be put into high-intensity operation, it is very likely that the clutch will fail or get stuck during the peak planting season, which will cause engine damage.

4.2 Inspection Methods and Treatment Measures

The problem was discovered not by high-end equipment, but by the following simple but effective methods:

| Steps | Means of inspection | Effectiveness |

| 1 | Comparison of pedal pedal feel | Detection of abnormal resistance |

| 2 | Visual inspection + flashlight + small mirror assistance | Observation of foreign objects and wear marks |

| 3 | Cotton swabbing the surface to find micro-cracks | Magnified observation of cracks to confirm risk areas |

| 4 | Replacement of pressure plate and friction plate in time | Avoidance of spreading of faults |

Tools used: movable wrench, stethoscope stick, cotton swabs, small mirror, simple lighting equipment

Replacement took less than 4 hours, and the cost of the parts used was about $600, which is a huge economic savings compared to a clutch blowout that resulted in damage to the mainframe (which usually takes 1.55 days to repair).

5. Proactive Parts Replacement Strategy

Once agricultural equipment is operated under high loads and long working hours, the natural wear and tear of its components is unavoidable. However, what really affects efficiency and safety is often not “wear and tear”, but “unexpected failure”. The establishment of a set of positive, front-loaded wear parts replacement strategy is the core of ensuring the continuity of agricultural time and reducing maintenance costs.

5.1 Use data to determine the replacement cycle, rather than “wait until it breaks”

Many farm machinery operators are accustomed to “use it until it breaks”, but this is a double loss in planting, harvesting, and other short-window, intensive operations, which can easily result in too little time for maintenance + yield impacts. Double loss.

Suggested Practices:

Record hours of use (with a digital meter or manual registration)

Create an equipment account (with historical data on oil changes, filter changes, seal changes, etc.)

Set up maintenance intervals for each condition:

Standard loads: follow the manual’s recommended frequency

Heavy loads or dusty/humid environments: 15-30% shorter intervals are recommended

Example Reference:

The manual for hydraulic filters on a certain farm suggests that the filter should be changed every 500 hours.However, the actual field humidity, heavy load, adjusted to every 400 hours to replace. It avoids frequent hydraulic jamming and waste of working hours in the past.

5.2 Replacement parts vs. original parts: rationally weighing cost and stability

When the budget is limited or the purchasing cycle is long, many operators tend to choose replacement parts. However, not all replacement parts are “labor-saving”.

| Item | Genuine parts | Replacement Parts (Branded Parts) | Replacement Parts (Branded Parts) |

| Cost | High | Medium | Medium |

| Fit | Perfect | Basic Match | Basic Match |

| Useful life | Consistent or slightly better | General | General |

| Reliability | High | Medium | Medium |

| Suggested use scenarios | Mainframe critical parts | Non-Critical Parts | Non-Critical Parts |

Operational recommendations:

For core components such as hydraulic pumps, engine seals, clutch plates, etc., give priority to original or branded parts

Non-critical components such as filters can be used with high-quality alternatives (with the same matching parameters)

Low-priced general-purpose parts are only used as a contingency option in case of tight inventories or interrupted transportation.

6. How MINNUO Supports Predictive Maintenance

While traditional agricultural machinery maintenance is mostly based on “failure response”, Predictive Maintenance focuses more on “early warning intervention”, so that maintenance and replacement can be completed before real damage occurs, avoiding downtime and losses. It is around this concept that MINNUO has built a multi-dimensional solution covering hardware, software and service.

6.1 Visualization of maintenance manuals + remote warning system: maintenance is no longer based on experience

MINNUO equipment is shipped with customized visualization of maintenance manuals, combined with on-site sensors and remote diagnostic platforms, to make the leap from “reading manuals” to “looking at data”. The leap from “reading manuals” to “looking at data” is realized.

Typical features:

Real-time record of equipment running time and load status

Automatic reminder of filter replacement and lubricant life

Real-time alarms of abnormal pressure/temperature/revolutionary speed are pushed to the operator’s mobile phone/backstage

Remote viewing of the status of multiple equipments in the cloud, which is convenient for the farmer to unify the scheduling

Practical application:

In a large farm in Henan Province, the Minnow Seeder was warned of “abnormal belt temperature rise” in advance during the critical operation period through the platform. “Belt temperature rise abnormality”, the user half a day in advance for replacement, to avoid the original 100 acres of operation plan delay, to ensure that the spring sowing window is not lost.

6.2 Highly Durable Design: Reducing Unscheduled Maintenance

In addition to relying on data prediction, MINNUO extends the natural life of the equipment body and key components at the product design stage through structural reinforcement, component selection, and corrosion-resistant coatings.

Key measures include:

Use of high-strength bearings and seals to adapt to high-frequency reciprocating impacts

Hydraulic system adopts a double anti-leakage structure to enhance the reliability of continuous operation

Use of anti-loosening and self-locking design of bolts at the joints reduces the risk of loosening after vibration

Coating protection adopts industrial-grade electrophoresis + powder spraying, which is resistant to corrosion of mud and water for more than 3 years

User Feedback:

A customer from the Russian Far East reported that the MINNUO tractor had been running trouble-free for 5 months, whereas his previous machine had required minor repairs every 2 months. The service life and utilization of man-hours have increased significantly.

6.3 Customized parts package service: intensity matching, risk control

MINNUO offers a combination of customized wearing parts packages for different working conditions (e.g. mountain slopes, desert dust, extreme cold). Combined with the information provided by the customer at the time of purchase of the intensity of the operation, crop type, regional climate conditions, the engineers will give a personalized spare parts matching program.

The customized package includes but not limited to:

High temperature grease / special hydraulic oil below freezing point

Thickened seals / extended filter element / impact resistant brake pads

Matching high life bearing and sprocket (to avoid the risk of off-standard replacement)

Advantage:

to avoid damage to the whole machine by non-compliant parts

Quick replacement on site, no need to wait for procurement

Adaptability to reduce the error of the installation of common parts brought about by the installation of the problem

Example:

A user in the Middle East reported that sandy weather caused frequent replacement of the cartridge, and MINNUO has been working with a customer for a long time. A customer in the Middle East reported that the filter element was replaced frequently due to sandy and dusty weather. MINNUO engineers recommended a three-stage filtration reinforcement kit, which extended the filter element replacement cycle from 7 to 15 days and reduced the overall cost by more than 20%.

Conclusion

The best time to recognize wear and tear is not after a failure occurs, but before the problem first appears. Through sensor monitoring, remote alerts, maintenance manuals and customized packages, this paper shows how to change the tractor maintenance strategy from “reactive repair” to “predictive prevention”. This not only extends the life of the equipment, but also avoids downtime during critical farm hours.

MINNUO promotes the concept of “discovery as prevention”, encouraging farm machinery users to adopt the habits of regular inspection, timely replacement and scientific management. We provide professional spare parts recommendations and personalized maintenance advice to help you identify potential wear and tear areas in advance, so as to avoid breakdowns affecting the overall situation.