In recent years, the proportion of agricultural land located in arid and semi-arid regions has increased significantly, particularly across the Middle East, North Africa, Central Asia, and western China. These regions face extreme climatic stressors—intense heat, low humidity, high UV exposure, and frequent sandstorms—which can push standard agricultural equipment beyond its design limits.

Under such conditions, conventional equipment configurations often fail to deliver stable performance. Problems such as lubricant evaporation, air intake contamination, rapid component wear, and cold-start failures become far more frequent. Farmers in these zones are increasingly asking: How can we ensure reliable operation without frequent breakdowns?

This article aims to answer that question by providing practical adaptation strategies in five key areas: model selection, lubrication system, air filtration, cooling mechanisms, and electrical components. Whether you’re a farmer in northern Sudan or on the Gobi frontier, these insights will help you prepare your machinery for harsh realities—and achieve greater uptime and longevity in one of the world’s toughest environments.

Contents

- 1 I. Typical Environmental Challenges in Arid Regions

- 2 II. Lubrication System Optimization: Combat Dry Friction

- 3 III. Air Filtration Enhancement: Keep Sand Out

- 4 IV. Cooling System Improvements: Fight Overheating

- 5 V. Electrical and Battery System Upgrade

- 6 VI. Rubber and Tire Adaptability: Resistance to Cracking and Thermal Decay

- 6.1 1. Tire material upgrading suggestions: high temperature resistance, ozone resistance, low volatility

- 6.2 2. Tread Anti-Radiation Coating Configuration

- 6.3 3. Recommendations for anti-corrosion of rubber parts (oil seals, shock absorbers, tracks)

- 6.4 4. Thermal Expansion Early Warning and Intelligent Protection Program

- 7 Conclusion

I. Typical Environmental Challenges in Arid Regions

Agricultural equipment operating in drought-prone regions faces a set of harsh and persistent environmental stressors. These challenges not only affect short-term performance but also significantly impact the long-term durability and maintenance frequency of the machinery. Understanding these stress factors is the first step toward effective adaptation.

1. Extremely Low Humidity and Precipitation

Annual precipitation often falls below 300 mm, with relative humidity frequently under 20%.

The dry air accelerates evaporation of lubricants, leading to dry friction, increased engine wear, and oil seal shrinkage or cracking.

Rubber components, such as tires, belts, and seals, become brittle and prone to cracking due to dehydration.

2. High Wind and Dust Concentration

Frequent sandstorms and high concentrations of airborne particulates cause:

Blockage and abrasion of air filters, resulting in reduced engine intake efficiency.

Infiltration of dust into hydraulic systems, bearings, and electrical housings, triggering premature component failure.

Equipment surface paint wears faster due to wind erosion, exposing metal to potential oxidation.

3. Large Diurnal Temperature Fluctuation

Daytime temperatures can exceed 40°C, while nighttime temperatures may drop below 5°C.

Cold-start difficulty arises in the early morning due to oil thickening and battery output instability.

Repeated thermal expansion and contraction accelerates the fatigue of engine parts and electrical connectors.

4. Intense Solar Radiation and Ground Reflection

Constant sunlight exposure causes:

UV-induced aging of plastics, wires, hoses, and control panels.

Significant heat buildup inside cabs, ECUs, and battery compartments.

Ground-reflected radiation in sandy areas doubles thermal exposure, stressing materials even further.

✅ Sublimation Insight:

These extreme environmental factors are not “exceptions” but “standard working conditions” in arid zones. Therefore, relying on generic factory configurations is inadequate. Regional customization and maintenance planning must be incorporated into procurement, design, and daily use.

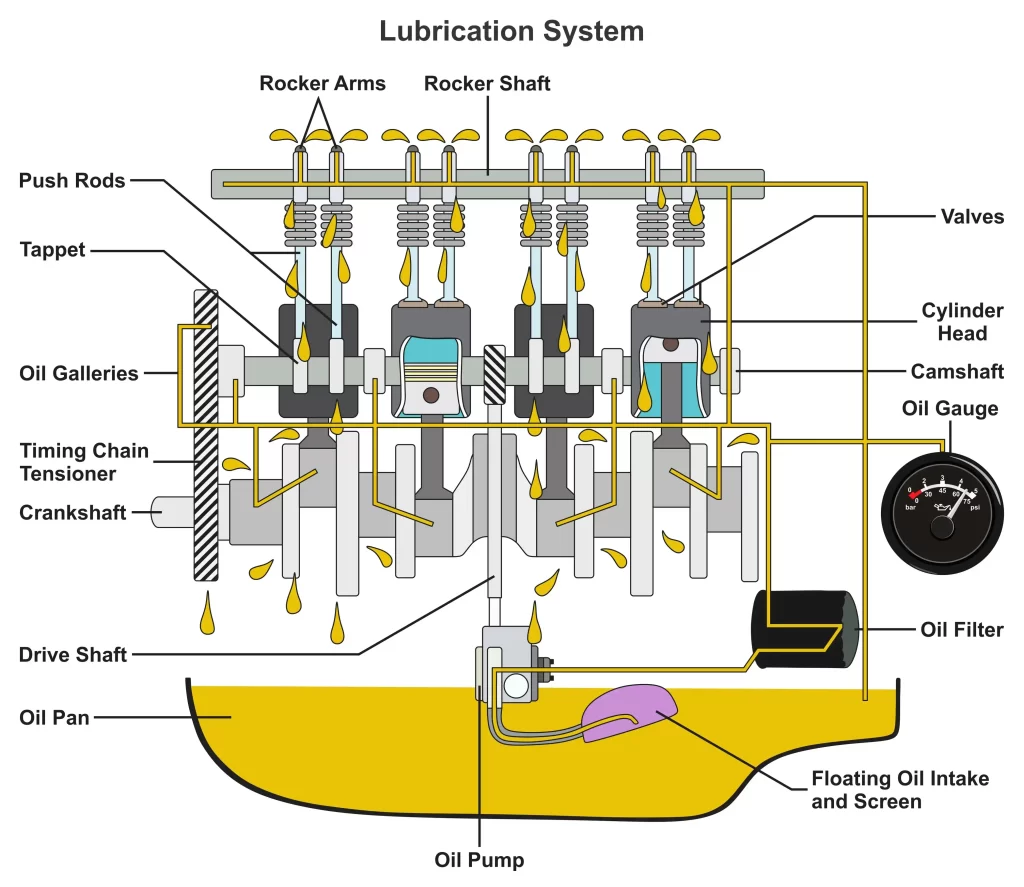

II. Lubrication System Optimization: Combat Dry Friction

In arid climates, dry friction is one of the most severe threats to the longevity of agricultural machinery. Low ambient humidity, high daytime temperatures, and constant wind-driven dust accelerate lubricant evaporation and degradation. A scientifically optimized lubrication system is therefore essential.

1. Use of Synthetic Lubricants with High Thermal and Oxidation Stability

Recommended oils: fully synthetic PAO or ester-based lubricants.

Performance traits:

Withstand ambient temperatures above 40°C without viscosity breakdown.

Resistant to oxidative thickening under prolonged exposure to air and heat.

Maintain consistent film strength during cold-starts at night.

✅ Tip: Select lubricants with viscosity grades like 15W-40 or 10W-50, ensuring fluidity during cool mornings and stability under midday heat.

2. Recommended Additives for Extreme Dry Environments

| Additive Type | Function |

| MoS₂ (Molybdenum Disulfide) | Forms solid film under pressure; resists dry metal contact. |

| ZDDP (Zinc Dialkyldithiophosphate) | Anti-wear + anti-oxidation; ideal for engine + gearbox. |

| PTFE Microparticles | Enhances lubrication film strength; reduces stick-slip under load. |

| Polymeric Viscosity Modifiers | Keeps oil stable under thermal cycles; prevents thinning. |

✅ Real-world value: These additives reduce engine start-up wear by up to 50% under high dust load environments.

3. Structural Improvements to Lubrication Systems

To reinforce system resilience under dry, dusty stress:

Sealing optimization:

Use high-elasticity fluororubber (FKM) or PTFE shaft seals to prevent oil leakage and air intrusion.

Install “dust baffle lips” on external lubrication ports to shield from sand ingress.

Monitoring and automation:

Integrate pressure + temperature + oil quality sensors with alert signals.

Consider inline oil condition sensors to predict degradation and reduce unplanned shutdowns.

✅ Advanced Option: MINNUO’s upgraded lubrication module supports “real-time viscosity feedback + ambient temperature compensation”.

4. Maintenance Recommendations: Adjusted for Dry Regions

Due to the faster degradation cycle in desert climates, standard service intervals are often insufficient:

Oil change cycle: Reduce from typical 500 hours to ≤300 hours, especially for engine and hydraulic systems.

Inspection checklist:

Check oil color, clarity, and odor every 100 hours.

Replace oil filters every 150–200 hours, or immediately after sandstorm exposure.

Conduct field-side rapid tests with dipsticks that detect metal debris or viscosity shift.

✅ Emergency Backup: Keep a portable lubrication refill kit with pre-filtered synthetic oil and anti-evaporation seals on board.

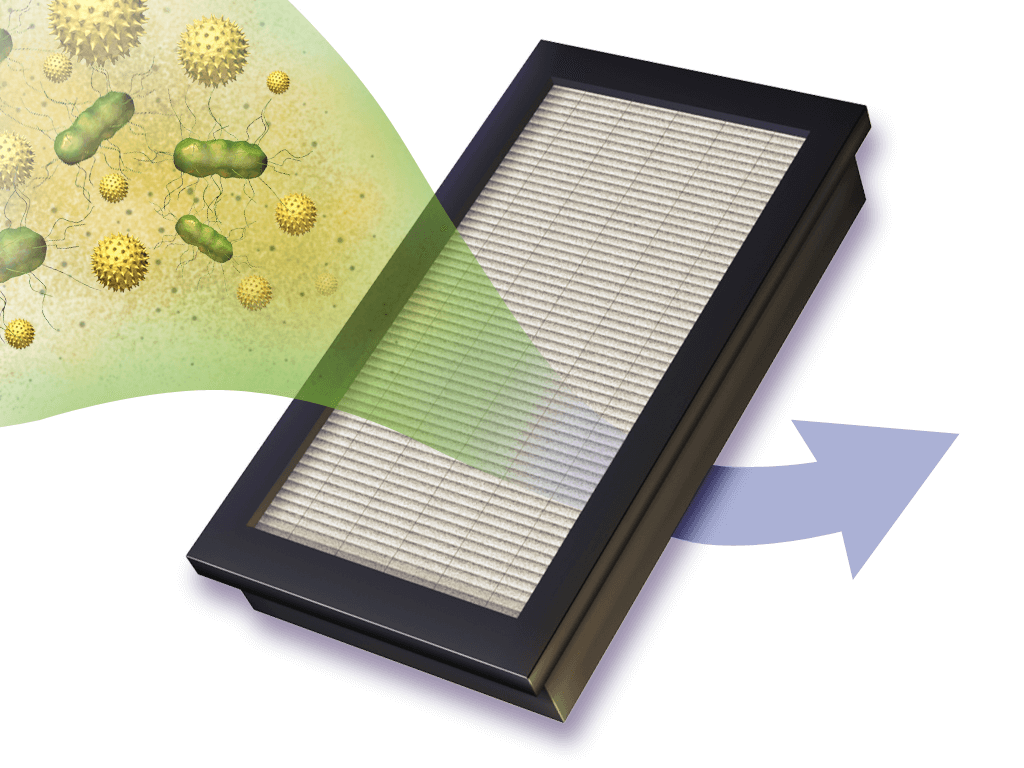

III. Air Filtration Enhancement: Keep Sand Out

In arid regions with high wind and sand, the concentration of suspended particles in the air is extremely high, posing a serious threat to the engine system, combustion efficiency and turbine life of agricultural machinery. Once the air filter is not efficient enough, sand particles enter the combustion chamber, which may lead to a series of problems such as cylinder pulling, early wear and power loss. Therefore, strengthening the air filtration system is the “first line of defense” to extend the life of the equipment.

1. Triple filtration structure: layered against the invasion of fine particles

Recommended configuration is as follows:

| Filter assembly | Function Description |

| ① Cyclone pre-separator | Extends the life of the main filter element by removing >80% of large dust particles ahead of time with the help of rotating airflow. |

| ② High-efficiency cotton main filter element | Captures small and medium sized particles (PM10-25), keeping the airflow clean and protecting the engine air intake system. |

| ③ Built-in oil cup dust collector | For secondary interception of residual particles, combined with an oil-attached structure to avoid blowback of fines and increase filtration accuracy to ISO 5011-F7. |

✅ It is recommended to use high pressure-resistant, washable filter cotton material to extend the use cycle of the filter element.

2. Common Problems and Identification Tips

Starting difficulty, power loss: sand and dust block the intake air, resulting in mixture concentration disorder;

Shortened filter life: after a sand attack, the filter life cycle is shortened from 300 hours to less than 100 hours;

Increased engine vibration, black exhaust: air is not flowing freely, combustion is not sufficient;

Air Flow Meter Failure: fine powder adheres to the sensor membrane surface, data abnormality.

3. Inspection and Replacement Maintenance Recommendations

In order to maintain the filtration efficiency of the system, a scientific inspection frequency needs to be established:

| Inspection Items | Recommended Cycle | Operating instructions |

| Filter Cartridge Visual Inspection | Every 50 hours or after wind and sand operations | Observe the dust layer on the surface of the filter element, whether it is deformed or clogged |

| Main Cartridge Replacement Intervals | No more than 100 hours | Especially in the period of frequent sandy and dusty weather, the filter element should be replaced in advance |

| Prefilter Cyclone Dusting | More than 3 days per week or consecutive dry operations | Tilt the dust collection cup and check that the rotor blades are not cracked. |

✅ Tip: The cartridge should not be “blown back” with compressed air, but should be cleaned by tapping or vacuuming. 4.

4. Configuration optimization suggestions

Recommended equipment:

MINNUO modular air pre-filter module for desert/Gobi operations, with the following features:

standard “cyclone + cotton + built-in oil cup” triple system;

filtration accuracy ≥ 99.7%; low wind resistance, stable air flow;

adapted to the engine power range of 40 ~ 180hp models, support customized adaptive interface; can be linked with the intake temperature sensor to monitor the filter element clogging. Support customized interface;

can be linked with the intake air temperature sensor to monitor the filter element blockage.

Extended customization options:

Blockage alarm device: triggers a beep when the differential pressure of intake air exceeds the warning value;

Quick-disassembly structure facilitates tool-less cartridge replacement in the field;

Cartridge illumination ring light for night operation improves maintenance efficiency.

IV. Cooling System Improvements: Fight Overheating

In arid, high-temperature, sandy and dusty operating areas, the cooling system of agricultural equipment often faces problems such as excessive load, weakened cooling effect, and component aging. If the cooling efficiency is insufficient, it will easily lead to engine overheating, oil deterioration, and even cause stalling and shutdown. Optimization of the cooling system is one of the key means to ensure the stable operation of the whole machine.

1. System structure optimization: air-cooled + oil-cooled combination is more reliable

For medium and large-sized models above 100hp, it is recommended to adopt dual-channel thermal management structure:

| Modules | Recommended Configurations | Role Description |

| Air-cooled systems | High Efficiency Aluminum Fin Condenser + Hydraulic Electronically Controlled Fan | The main source of heat dissipation, rapid heat conduction and variable speed control of air flow |

| Oil-cooled systems | Oil Cooling Module + Forced Circulation Pump | Auxiliary cooling of hydraulic oil, high temperature oil and other heat sources to prevent viscosity loss |

| Linkage systems | Dual Temperature Zone Control + Logic Determination Module | Intelligent judgment of no load/heavy load/operational state of the fan speed adjustment |

✅ Tips: Many MINNUO devices support “wind-oil integrated cooling assembly”, which is suitable for operation under high-temperature load scenarios. 2.

2. Suggested control method: temperature control + variable frequency automatic fan

Traditional constant speed fan wastes power in high temperature and low load or intermittent working conditions, modern cooling strategy should be based on the working conditions of the linkage control:

| Control Format | Recommended Configuration | Advantages |

| Temperature Sensing Controller | Installation in coolant channel / oil return | Accurately sensing the source of heat, intelligent fan speed regulation |

| PWM Speed Control Electric Fan | Support 0~100% stepless speed regulation, current feedback monitoring status | Energy saving, noise reduction, prolonging the life of the fan |

| Heavy Duty Operation Priority Mode | The device detects high load and automatically switches to “full speed cooling” mode. | Prevents high temperature lag resulting in insufficient heat dissipation |

✅ Practical advice: speed fan should be equipped with overheating protection, and set the “fault code display” function to facilitate the maintenance judgment. 3.

3. Coolant optimization and heat dissipation maintenance in high temperature environment

In the hot arid environment, the coolant evaporates quickly and scales more, which is a common problem, and the cooling medium should be managed in tandem with the maintenance:

Suggestions for the selection of coolant:

Recommend the use of saline and alkali composite coolant (with anticorrosion inhibition of scaling);

High temperature zone is recommended to configure a special heavy-duty coolant with a boiling point of 120 ° C or more;

Replacement every 1000 hours or early replacement according to the hardness of mineralized water. Replacement every 1000 hours, or in advance according to the hardness of mineralized water.

Radiator daily maintenance points:

Weekly cleaning of the radiator air inlet network, to avoid the accumulation of sand and dust leading to a decline in thermal conductivity;

If the high temperature operation is frequent, it is recommended to add the “forward and reverse blowing fan” function;

Radiator surface rinsed regularly with a high-pressure water gun (to avoid corrosion of aluminum with alkaline cleaners);

Check the pipeline is aging, whether expansion kettle is closed to prevent leakage of pressure. Check whether the pipeline is aging and whether the expansion kettle is well closed to prevent pressure leakage.

V. Electrical and Battery System Upgrade

Drought and high temperature climatic conditions can pose a serious threat to the electrical and storage systems of agricultural machinery. Prolonged sun exposure, cable heating, dust erosion, cold start difficulties and other problems occur frequently, seriously affecting the starting performance and electronic control system life. Therefore, the cable material, battery type, cold start system must be optimized exclusively.

1. High-temperature aging-resistant cable selection suggestions

Long-term exposure to high temperatures, ordinary PVC cables are prone to: hardening of insulation, cracking and leakage, loose joints, which leads to the risk of start-up failure or short-circuit.

| Recommended Configurations | Technical Parameters | Application note |

| Silicone Rubber High Temperature Cable | Temperature resistance ≥ 120°C, UV aging resistance | For engine compartment, high voltage ignition coils, positive and negative battery cables |

| Low Smoke Halogen Free High Flame Retardant Sleeving | Heat-shrink protection, improve insulation level | Recommended for wiring in centralized wiring harness areas and electrical control box wiring |

| Multi-Core Braided Shielded Cable | Strong anti-interference, improve CAN/ECU signal stability | Especially suitable for devices with autopilot or remote modules |

✅ Additional Suggestions: Wiring harness installation location to avoid engine exhaust, oil cooler radiator and other high heat source areas, reasonable wiring + heat reflective wrapping more reliable.

2. Electrical connection and sealing protection enhancement

High dust and low humidity and high temperature environment, the electronic control module connector is very easy to poor contact, water vapor condensation corrosion and other issues, should be strengthened by the following means of sealing level:

All key connectors should meet the IP67 dust and waterproof grade;

electronic control box cover using rubber seals or full plastic structure;

waterproof adhesive potting sealing or heat-shrinkable sealing sleeve at the connectors;

CAN/ECU plug with double-locking structure to prevent vibration loosening. Plugs with double locking structure, anti-vibration loose.

✅ MINNUO electronic control system factory configuration has supported the “dust storm level” high temperature connectors standard. 3.

3. Battery System Upgrade: Heat Resistance + Stable Output

Battery failure rate doubles under high temperature environment, and common problems include: electrolyte evaporation, electrode plate expansion and deformation, and increased self-discharge.

| Configuration Recommendations | Technical Description | Advantages |

| AGM Valve Regulated Sealed Batteries | Adsorption type glass fiber partition, high temperature resistance 60°C | Low self-discharge rate, maintenance-free, vibration-resistant, suitable for field operation |

| Thermal Battery Protection | Automatic power-off protection for detecting excessive temperature rise | Prevents the battery from overheating and short-circuiting or burning, prolonging the service life |

| Solar Charging + Voltage Compensation System | Daytime replenishment, nighttime voltage stabilization | Suitable for on-site operation areas or open storage areas, guaranteeing a constant voltage for successful starting |

✅ Recommended practice: supporting 20W-60W small solar panel, used for equipment after a long period of time to maintain the state of slow charging. 4.

4. Cold start system auxiliary device configuration

Day and night temperature difference (day 40 ° C, night <5 ° C) is easy to cause the engine “thermal expansion and contraction” imbalance, cold start is difficult, it is recommended to equip with:

oil heater (automatic heating): improve the temperature of diesel fuel, reduce the phenomenon of ‘smoke’ and “ignition”; dual battery parallel system; dual battery parallel system: for the equipment after a long period of parking slow charging maintenance state. It is recommended to equip with: Oil circuit heater (automatic heating): to increase the diesel temperature and reduce the phenomenon of “black smoke” and “failure to ignite”;

Dual battery parallel connection system: to enhance the starting current capacity;

Preheating Plug Intelligent Control System: to heat up the combustion chamber automatically before starting to increase the success rate of the first ignition.

✅ MINNUO new 100+hp or above equipment is equipped with dual battery and oil preheating system as standard, which can realize the smooth ignition in the cold morning of -15°C.

| Projects | Recommended Configurations | Addressing Environmental Risks |

| Cable Systems | ≥120°C high-temperature cable + sun-protective wrapping | Resistant to heat, UV, and insulation deterioration |

| Connector Systems | IP67 sealed connector + heat-shrinkable waterproof envelope | Water, Sand, and Vibration Resistant |

| Battery Systems | AGM battery + thermal cutoff protection + solar recharge | Improves start rate and extends battery life |

| Cold Start Auxiliary | Oil-heated, dual batteries, smart preheat plugs | Improves morning start success rate |

VI. Rubber and Tire Adaptability: Resistance to Cracking and Thermal Decay

In arid zones, due to strong ultraviolet rays, large temperature differences between day and night, and significant radiation from high ground temperatures, tires, seals, rubber tracks, and other soft parts of agricultural equipment are extremely susceptible to aging and cracking, which can cause oil leaks, tire blowouts, and risk of loss of control of performance. Therefore, the rubber and tire system must have the dual ability of anti-dry heat and anti-carbonation.

1. Tire material upgrading suggestions: high temperature resistance, ozone resistance, low volatility

tire rubber in the ground > 55 ℃ above long-term exposure is prone to “heat aging” and “hardening cracking”, it is recommended to use the following properties of the rubber carcass:

Butyl rubber sealing material (IIR): excellent resistance to ozone and ozone, and the performance of the runaway tire. Butyl rubber sealing material (IIR): excellent ozone resistance and air tightness;

EPDM rubber outer ply: high temperature aging resistance, UV resistance, suitable for long time downtime in hot area;

Aramid fiber reinforced structure: enhance the resistance to side cut and tread tearing strength.

✅ Recommended: M+S marked wide tread tires for agricultural machinery with dynamically adjustable tire pressure range of 0.6 to 1.2 bar, more adaptable to sandy/earth slopes.

2. Tread Anti-Radiation Coating Configuration

Arid areas are often accompanied by strong solar radiation and surface reflections (e.g. saline and sandy ground), which result in severe heat absorption in the tread and a spike in tire pressure, causing the risk of flat tires.

| Coping Strategies | Technical recommendations | Effectiveness |

| Radiopaque Coating for Outer Tires | Coated with white ceramic granule reflective adhesive | Cooling effect up to 10-15°C, slowing down the aging of the carcass |

| Intelligent Tire Pressure Regulator | Manual/automatic adjustment of tire pressure + bleed-off | Improvement of the adaptability to “soft ground + high temperature difference” |

| Tread Spraying with Anti-Cracking Grease | Regular spraying of anti-carbonation oil film (paraffin + polyether system) | Improvement of elasticity retention and reduction of the risk of static cracking. |

✅ MINNUO Arid Zone Crawler Tractor platform has integrated anti-radiation tread protection + adjustable tire pressure interface. 3.

3. Recommendations for anti-corrosion of rubber parts (oil seals, shock absorbers, tracks)

Many seals/bushings/dust rings in agricultural machinery are “hidden consumables”, which often fail due to heat shrinkage + carbonization:

All seals are recommended to be made of high-temperature silicone / Viton (≥180°C);

Tracks are recommended to be made of neoprene: resistant to gravel, impact, ground heat and UV; for frequently moving rotary axles, floating tread protectors + adjustable tire pressure interface are installed; for the track, the track is recommended to be made of neoprene: resistant to impact, ground heat and UV. Impact, ground heat and UV resistant;

For the rotary shaft with frequent activities, installing the floating oil seal structure can extend the service life to more than 1000 hours.

✅ Additional suggestions: For the surface of tires and tracks of equipment in non-use season, spray silicone-based maintenance fluid or wrap sunscreen cloth regularly to avoid static carbonization.

4. Thermal Expansion Early Warning and Intelligent Protection Program

Under the environment of large temperature difference, the tire thermal expansion and contraction is serious, if the operation of the tire pressure is abnormally high will lead to tread bursting or de-beading, it should be configured:

| Function Module | Configuration Suggestions | Effect Description |

| Tire Pressure Warning Sensor | Wireless Tire Pressure + Temperature Sensor (TPMS) | Real-time monitoring of tire pressure to prevent high tire temperature operation |

| Flameproof Pressure Relief Valve | External Pressure Relief Fitting + Self-Control Pressure Relief Membrane | Active air release in case of high temperature to prevent bursting |

| Smart Tire Temperature Probe | Embedded Tire Core Monitoring Heat Accumulation | Early warning of the risk of high heat through sound and light reminders |

Conclusion

Agricultural equipment adapted to arid regions is not a single point of adjustment, but a systematic integration of suitable model selection, structural optimization and high-frequency preventive maintenance. Faced with the challenges of extreme heat, dust storms, low humidity and large temperature differences between day and night, farms can only achieve the long-term goal of reducing failure rates and extending the life of machinery if they build climate-resilient systems.

From anti-evaporation lubrication and multi-stage dust removal filtration, to active cooling modules and high-temperature electrical upgrades, every detail is critical in arid terrain. Maintenance is not an afterthought, but part of an adaptation strategy.

MINNUO continues to provide durable and climate-resilient equipment solutions for users in arid regions. With optimized filtration packages, crack-resistant tires, heat-resistant circuits and intelligent maintenance interfaces, MINNUO helps users maintain consistent performance in harsh climates, making every job more predictable and every harvest safer.