Combine harvesters are a big deal in agriculture. They’re the machines that let us harvest crops efficiently. This guide is for people who want to buy a combine or just learn about them.

Contents

- 1 What is a Combine Harvester?

- 2 History and Evolution of Combine Harvesters

- 3 Main Components of a Combine Harvester

- 4 How a Combine Harvester Works

- 5 Detailed Example of How a Combine Harvester Works

- 6 Types of Combine Harvesters

- 7 Key Features to Consider When Buying a Combine Harvester

- 8 Maintenance and Care of Combine Harvesters

- 9 Benefits of Using Combine Harvesters

- 10 Challenges and Considerations

- 11 Future Trends in Combine Harvesters

- 12 Conclusion

What is a Combine Harvester?

A combine harvester is a type of agricultural machinery used for harvesting, threshing and cleaning grain.

Why They’re Important

Combines do three main things: they cut the crop, they separate the grain from the stalks and chaff, and they clean the grain. That’s why they’re so important in farming today.

History and Evolution of Combine Harvesters

Early Combines: People started working on combines in the 1800s. The first ones were pulled by horses and were pretty basic.

New Technology: Combines got a lot better when people started using steam engines and then gasoline engines. Today’s combines have lots of electronics and GPS.

Main Components of a Combine Harvester

- Header: The front part of the combine that cuts and picks up the crop. There are different headers for different crops.

- Reel: The reel is on top of the header. It helps guide the crop into the cutting part.

- Cutter Bar: The cutter bar is a big blade that cuts the crop close to the ground.

- Threshing Drum: The threshing drum beats the crop to get the grain out of the stalks.

- Straw Walkers: Straw walkers help move the straw out of the threshing drum and onto the ground or into a bin.

- Cleaning System: The cleaning system uses screens and fans to clean the grain by getting rid of the chaff and other stuff.

- Grain Tank: The grain tank holds the clean grain until it’s time to dump it.

- Unloading Auger: The unloading auger moves the grain from the tank to a truck or wagon.

How a Combine Harvester Works

A combine harvester is a complicated machine that does a lot of things to harvest grain crops. The main steps are cutting, threshing, separating, cleaning, and storing. Here’s how a combine harvester works:

Cutting:

- Header: The process starts with the header, which cuts the crop close to the ground. The header has a cutter bar with a bunch of sharp blades or sickles.

- Gathering the Crop: As the combine moves forward, the reel (a bar with teeth or tines that spins) pushes the cut crop toward the auger (a big screw that spins). The auger moves the crop toward the middle of the header, where it goes into the feeder house.

There are headers for grain crops like wheat and barley, headers for corn, and headers with belts to move the crop gently.

Threshing:

- Feeder House: The feeder house uses a chain and slat conveyor to move the crop from the header to the threshing part. You can change the speed and amount of crop going into the threshing part.

- Threshing Drum or Rotor: Inside the threshing part, the crop goes into a spinning drum or rotor with rasp bars or spikes. The drum or rotor beats the crop to get the grain out of the stalks.

- Concave Section: Below the drum is a concave section with a grate-like surface. As the drum spins, the grain rubs against the concave. The grain falls through the holes, but the bigger pieces of straw stay on top.

Separating:

- Straw Walkers or Rotors: The straw that’s separated from the grain goes along straw walkers or rotors. Straw walkers shake the straw to get any remaining grain out. Rotors use spinning to separate the grain from the straw.

- Grain Separation: During this step, the grain that fell through the concave goes onto screens. The straw and chaff go out of the machine.

Cleaning:

- Cleaning System: The grain goes through screens that get rid of the bigger stuff. A big fan blows air through the screens to lift and get rid of the lighter chaff and other stuff. The screens and air make sure only clean grain goes to the grain tank.

- Chaff Spreader: The chaff either goes back onto the field to help the soil or goes into a separate pile for other uses.

Storing and Unloading:

- Grain Tank: The clean grain goes up into the grain tank using elevators and augers. The grain tank is a big storage area on the combine. Different combines have different-sized grain tanks. Some hold a few hundred bushels, and others hold over a thousand bushels.

- Unloading Auger: When the grain tank is full or the combine is done harvesting, the grain goes from the tank to a truck or wagon using the unloading auger. The auger can move around and get to the truck, so you can keep unloading without stopping the combine.

Detailed Example of How a Combine Harvester Works

Let’s walk through an example of how a combine harvester works in a wheat field:

- Setting Up the Combine: The operator selects the right header for wheat and adjusts the settings for cutting height, drum speed, and concave clearance based on the crop condition and desired grain quality.

- Starting the Harvest: The combine moves forward, and the header cuts the wheat stalks just above the ground. The reel guides the cut stalks toward the auger, which takes the crop into the feeder house.

- Feeder House Transport: The crop is carried into the threshing drum where it gets beat up, and the wheat grains separate from the stalks.

- Threshing and Separating: The separated grains fall through the concave, while the straw gets moved along by straw walkers. The straw eventually gets thrown back onto the field.

- Cleaning the Grain: The grains go through the cleaning system, where sieves and fans get rid of any remaining chaff and impurities. The clean grain then goes up into the grain tank.

- Storing and Unloading Grain: As the grain tank fills up, the operator uses the unloading auger to move the grain into a waiting trailer, which will take it to storage facilities.

Types of Combine Harvesters

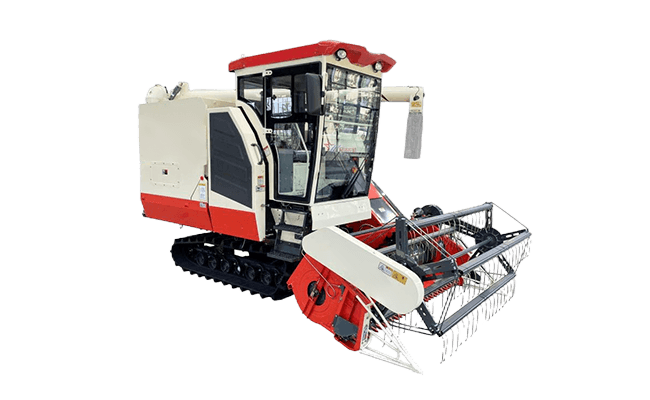

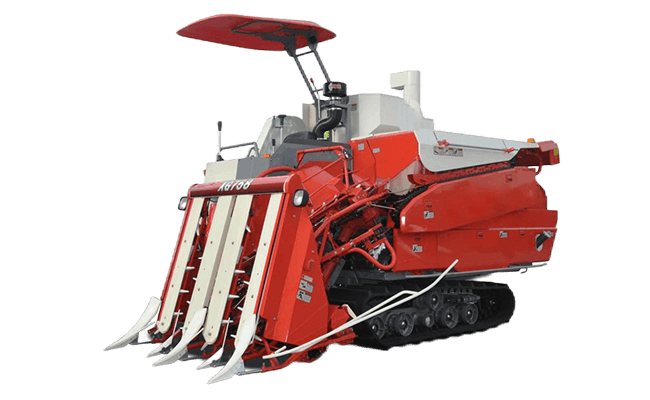

Self-Propelled Combines

These are the most common and versatile, capable of handling various crops with different headers.

Pull-Type Combines

These are pulled by a tractor and are less common but useful for smaller operations.

Rotary Combines

Use a rotating mechanism for threshing and separation, known for handling high moisture crops effectively.

Key Features to Consider When Buying a Combine Harvester

- Capacity: The size of the grain tank and how much the machine can process in a given amount of time.

- Engine Power: A more powerful engine can handle tougher conditions and larger operations.

- Headers: The ability to switch out headers for different crops can be a big deal.

- Technology Integration: Things like GPS, auto-steering, and yield mapping can make a big difference in how efficient you are.

- Maintenance and Support: Can you get parts? Can you get service?

- Fuel Efficiency: It costs money to run these machines, so fuel efficiency is a big deal.

Maintenance and Care of Combine Harvesters

Regular Inspection: Check for wear and tear on things like belts, chains, and bearings.

Cleaning: Keep the combine clean to prevent crop residue from building up, which can cause mechanical issues.

Lubrication: Make sure everything that moves is well-lubricated to reduce friction and wear.

Storage: Store the combine in a dry, covered area to protect it from the elements.

Off-Season Maintenance: Do a thorough job of maintenance during the off-season to get ready for the next harvest.

Benefits of Using Combine Harvesters

Efficiency: Combines save a ton of time and labor when it comes to harvesting.

Versatility: You can use them for all kinds of crops by changing out the header.

Yield Maximization: Efficient harvesting reduces grain loss and maximizes yield.

Technological Advancements: Modern combines come with technology that makes them more productive and easier to run.

Challenges and Considerations

Cost: They’re expensive to buy and operate.

Complexity: They require skilled operators and regular maintenance.

Field Size: They’re best suited for bigger fields and may not be cost-effective for small-scale operations.

Terrain: They work best on flat or gently rolling terrain.

Future Trends in Combine Harvesters

Automation: We’re moving toward autonomous combines with advanced AI and machine learning capabilities.

Sustainability: We’re working on making combines that are more fuel-efficient and environmentally friendly.

Connectivity: We’re getting better at connecting combines so we can monitor them and analyze data in real-time.

Conclusion

Combine harvesters are a big deal in modern agriculture because they save a ton of time and labor. Knowing how they work and what to look for when you’re buying one will help you make a good decision and get the right machine for you.

FAQs

Combines can harvest a wide variety of crops including wheat, corn, soybeans, barley, oats, and more, with the right headers.

Think about things like the size of your farm, the crops you grow, your budget, and the availability of service and support.

You need to inspect, clean, lubricate, and do off-season maintenance to keep a combine running well.

Look for things like GPS guidance, auto-steer, yield mapping, and connectivity options for real-time monitoring.