In this harvest season, are you worried about how to better preserve your grains? Do you want to know how to keep your grains dry and free from mold during storage? How can you extend the freshness of your grains and increase their market value? At this point, the grain dryers act as your “guardian” in the fields, safeguarding your harvest.

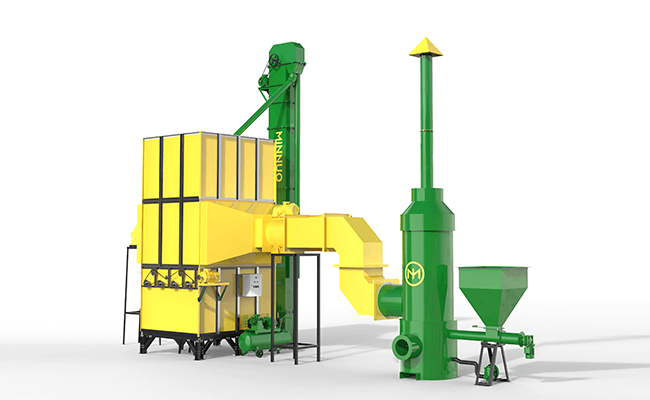

So, what exactly is a grain dryer? Simply put, it is a device that reduces the moisture content of grains through hot air circulation. By using a grain dryer, you can effectively extend the shelf life of your grains and reduce losses during storage and transportation.

Are you ready? Next, I will explore important topics with you, such as the working principles of grain dryers, tips for choosing the right one, different types available, maintenance techniques, and future market trends. Let’s see how grain dryers play a vital role in modern agriculture!

Contents

1. What is a Grain Dryer?

In simple terms, a grain dryer is a device used to reduce the moisture content of grains. It works by circulating hot air to evaporate moisture from the grains, which helps with preservation and storage. Grains like rice, wheat, and corn can suffer from high moisture after harvest, leading to mold, sprouting, or even rot. Therefore, using a grain dryer effectively extends the shelf life of your grains and ensures they remain safe during storage and transportation.

2. How Does a Grain Dryer Work?

So, how does this seemingly simple device operate? The working principle of a grain dryer is not complex and can be broken down into several key steps:

- Heat Source: A grain dryer needs a heat source to heat the air. Common sources include fuel oil, natural gas, and electricity.

- Air Circulation: The fan inside the dryer pushes the heated air into the drying chamber while expelling moisture, allowing for a continuous air cycle.

- Moisture Evaporation: As the hot air passes through the layer of grains, it evaporates the moisture, and the fan removes the humid air, gradually reducing the moisture content of the grains.

- Temperature and Humidity Control: Modern grain dryers usually come equipped with temperature and humidity sensors. These sensors monitor the drying process in real-time, ensuring that the grains dry evenly and without damage.

3. Factors to Consider When Choosing a Grain Dryer

Before purchasing a grain dryer, understanding your needs is crucial. Let’s discuss the key factors you should consider when buying a grain dryer:

- Drying Capacity:

- The first factor to think about is the capacity of the dryer, which refers to the amount of grain it can handle in a given time. If you have a large farming area, choosing a high-capacity dryer can significantly boost your efficiency.

- Type of Heat Source:

- Different heat sources can affect the operating costs and efficiency of the dryer. For example, while fuel oil dryers may have a lower initial investment, the long-term fuel costs can be higher. On the other hand, electric heaters perform better in energy consumption but may come with a higher equipment cost.

- Ease of Operation:

- It is very important to choose equipment that is easy to operate and maintain. Modern grain dryers often come with automated control systems, allowing you to monitor temperature and humidity in real-time through a display. This feature helps reduce human error.

- Durability and Brand Reputation:

- When purchasing equipment, opting for well-known brands usually offers better after-sales service and higher durability. Checking user reviews and recommendations can guide you in making an informed choice.

- Price and Budget:

- Finally, you must consider your budget. There is a wide range of prices for grain dryers in the market. By planning your budget wisely and looking for cost-effective options, you can save money without sacrificing quality.

4. Types of Grain Dryers

After understanding the basic concept of grain dryers, you might wonder what different types are available on the market. Here, we will briefly introduce several common types:

Static Dryer:

This type typically consists of a drying chamber and a heat source, where grains sit still inside. While it is simple to operate, the drying speed is relatively slow, making it suitable for small-scale farms.

Fluidized Bed Dryer:

This dryer uses hot air to make grains float within the drying chamber. It offers even and rapid drying, which is ideal for large-scale production.

Continuous Dryer:

A continuous dryer allows for the constant input and output of grains. This type is suitable for bulk drying and industrial production, saving both time and labor.

Mobile Dryer:

This equipment is flexible and convenient, allowing for drying in various locations. It is especially effective for immediate processing right after harvest in the fields.

5. Tips for Maintaining and Caring for Grain Dryers

Proper maintenance and care can extend the lifespan of your grain dryer. Here are some practical suggestions:

- Regular Cleaning: Keep both the interior and exterior of the dryer clean. Regularly remove grain residues and dust to avoid blockages and ensure efficient operation.

- Check the Heat Source: Periodically inspect the performance of the heat source equipment to ensure there are no leaks or malfunctions that could affect the drying results.

- Lubricate Mechanical Parts: Regularly add lubricant to mechanical components like fans and motors to reduce wear and ensure smooth operation.

- Monitor the Electrical System: Check the electrical system regularly to prevent short circuits and leakage issues, which can pose safety risks.

- Read the User Manual: Before using the equipment, carefully read the user manual. Following the manufacturer’s recommendations and maintenance guidelines can help you avoid many unnecessary issues.

6. Market Prospects for Grain Dryers

As the global demand for food security and quality continues to rise, the market demand for grain dryers is gradually increasing. In the future, with advancements in technology and the modernization of agriculture, grain dryers will evolve towards being more intelligent and environmentally friendly. The application of automation, remote monitoring, and other technologies is expected to significantly enhance drying efficiency and reduce energy consumption, providing farmers with greater profits.

7. Conclusion

Grain dryers play an essential role in modern agriculture. Choosing the right dryer not only improves the storage quality of grains but also minimizes losses and increases profits. I hope this article helps you gain a deeper understanding of grain dryers so that you can make the best choice for your agricultural needs in the future. If you have more questions about grain dryers, feel free to visit our website. Together, let’s move towards a brighter agricultural future!