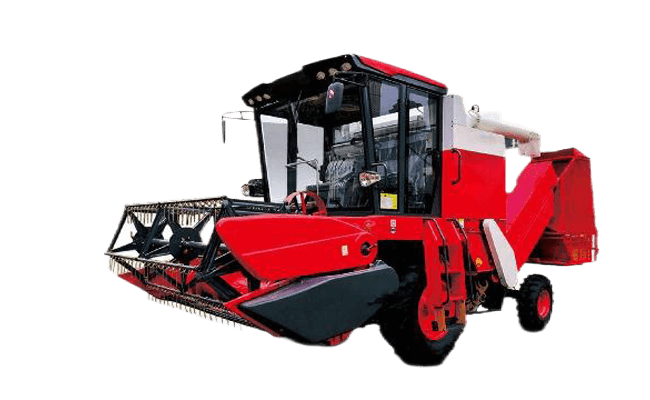

When crops enter the harvest season, vast golden fields await farmers. In the past, everything was done by hand, but now, with combine harvesters, everything is simpler and more efficient. A combine harvester isn’t just a machine in the field; it’s the “Iron Man” of modern agriculture.

The combine harvester integrates cutting, threshing, separating, and cleaning functions, allowing the entire harvesting process to happen in one go. It eliminates the need for multiple steps and tools. With just one machine, grain crops can be quickly and efficiently harvested, reducing the time and labor required. Harvesting becomes easier and more convenient.

In this article, let’s take a closer look at this revolutionary equipment and uncover its mysteries.

Contents

- 1 Why is it called a “combine harvester”?

- 2 How Does the Combine Harvester Get It All Done? Unveiling the “One-Step” Harvesting Process

- 3 Which Combine Harvester Fits Your Terrain? Choose the Right Harvesting Partner

- 4 The “Super Gear” of the Combine Harvester: In-Depth Analysis of Core Components

- 5 Easy-to-Learn Operating Tips: How to Maximize the Efficiency of Your Combine Harvester

- 6 Time-Saving and Effortless! Top Reasons to Use a Combine Harvester

- 7 How to Choose the Right Combine Harvester: Brand, Price, and Practicality Uncovered

- 8 What Are the Maintenance Costs of a Combine Harvester? Daily Maintenance Is Essential!

- 9 Curious About the Latest in Combine Harvester Technology? Future Trends Unveiled

- 10 Conclusion

Why is it called a “combine harvester”?

The combine harvester gets its name from the way it combines multiple harvesting functions into one machine. Traditional harvesting required several steps, including cutting, threshing, separating, and cleaning. Each step needed a different tool, but the combine harvester brings all these functions together in one piece of equipment. With this combined design, farmers can complete the entire harvesting process using a single machine, greatly increasing efficiency and reducing the need for manual labor. This integration also allows the combine harvester to handle various crops, from grains to beans, all with just one machine!

How Does the Combine Harvester Get It All Done? Unveiling the “One-Step” Harvesting Process

- One-Step Harvesting Process: The combine harvester integrates the four main functions—cutting, threshing, separating, and cleaning—into a single machine, allowing it to complete all steps in one pass through the field.

- Precision in Motion: Learn how the cutter, thresher, separator, and cleaning systems work together to achieve efficient and precise harvesting results.

- Storage and Transport: Discover how harvested grains move into the harvester’s storage tank, ready and waiting for unloading.

Which Combine Harvester Fits Your Terrain? Choose the Right Harvesting Partner

- Wheeled Combine Harvester: Ideal for broad, flat fields, this type works at high speed and efficiency, making it a popular choice for large-scale crops.

- Tracked Combine Harvester: Perfect for wetlands and uneven terrain, this model excels in muddy environments, such as rice paddies.

- Small Combine Harvester: Best suited for small farms and narrow fields, this compact option offers convenience and versatility for diverse needs.

The “Super Gear” of the Combine Harvester: In-Depth Analysis of Core Components

- Header: Explore how the header efficiently cuts crops and directs them toward the threshing mechanism.

- Threshing Drum: Get a detailed look at the threshing process and how the threshing drum separates the grains from the stalks.

- Separation and Cleaning Systems: Learn how these systems ensure a high yield of pure grain, free from impurities.

- Grain Tank and Unloading System: Discover the simple storage and unloading process that makes transportation easier and more efficient.

Easy-to-Learn Operating Tips: How to Maximize the Efficiency of Your Combine Harvester

Harvesting Speed and Efficiency Control

- Optimal Speed Settings: Adjusting the machine’s speed is crucial, as running too fast or too slow can impact both efficiency and quality. On flat, dry ground, slightly increasing the speed can accelerate the harvesting process. However, on uneven terrain, dense crops, or wet conditions, slower speeds help prevent blockages and reduce crop damage. Generally, select a speed that matches crop density, moisture, and harvester specifications.

- Consistent Feed Rate: Maintaining a steady feed rate, or the rate at which crops enter the header, prevents blockages and ensures thorough threshing. Avoid drastic changes in feed speed for smooth operation. Most harvesters have recommended speed ranges in the manual, so adjust based on your machine’s specifications.

- Fuel-Saving Driving Techniques: Avoid frequent acceleration or deceleration, as it wastes fuel and increases wear on the machine. Keep a steady speed, minimize stops or reversals, and aim for smooth, efficient harvesting in the field.

Adjustments for Terrain and Crop Conditions

- Terrain Adaptability: On muddy or wet fields, operate at lower speeds and consider using a tracked harvester to prevent sinking or compacting the soil. For flat, dry fields, a wheeled harvester works well, and speed can be increased accordingly.

- Crop Adaptability: Different crops require specific header height and threshing settings. For instance, wheat and corn require different threshing speeds due to wheat’s smaller, more delicate grains. Lower the threshing speed for wheat, while corn needs a higher speed to ensure effective threshing. Many modern combine harvesters allow easy adjustments to match crop type.

- Header Height Adjustment: The header height impacts harvesting quality directly. Adjust the header based on crop height and maturity to avoid cutting too deep or shallow. For mature rice, lower the header to cut closer to the roots, while for tall corn, raise the header to leave some stalk, reducing strain on the harvester.

Time-Saving and Effortless! Top Reasons to Use a Combine Harvester

- Saves Time and Labor: Comparing manual harvesting to machine harvesting highlights how the combine harvester frees up hands and saves valuable time.

- Efficient and Economical: High-efficiency harvesting brings economic benefits, such as faster harvest speeds and reduced labor costs, making it a smart financial choice.

- Reduces Crop Loss: The precision of the combine harvester minimizes crop loss during harvesting, leading to higher yields and improved productivity.

How to Choose the Right Combine Harvester: Brand, Price, and Practicality Uncovered

- John Deere: Known for durability and outstanding after-sales service, making it ideal for long-term investments.

- Case IH: Features a highly efficient threshing system, perfect for large-scale farming needs.

- New Holland: Emphasizes energy efficiency and high productivity through innovative technology, well-suited for eco-conscious farmers.

When considering budget, it’s wise to base it on field size and the frequency of use. For occasional use, lower-priced models or rental options may be more practical. Frequent users should invest in durable, high-end brands. Additionally, after-sales service and parts availability differ by brand, so it’s important to select a provider that ensures long-term, efficient operation.

To Rent or Buy? Choosing Based on Usage Needs

For small farms or those with limited annual use, purchasing a combine harvester might not be the most economical option. Renting provides a more flexible solution in such cases:

- Advantages of Renting: No need to pay high upfront costs or worry about maintenance. Simply cover the rental fee when needed.

- Advantages of Buying: For high-frequency use, purchasing is more cost-effective over time. Ownership allows access to the equipment whenever necessary.

To make a sound decision, compare annual crop harvest volume, rental fees, and maintenance costs. Testing rented equipment on large tasks can help determine whether it meets the farm’s needs before making a long-term commitment.

What Are the Maintenance Costs of a Combine Harvester? Daily Maintenance Is Essential!

Purchasing a combine harvester is only the first step; daily maintenance is crucial to ensuring long-term, efficient operation. Here are some primary maintenance costs to consider:

- Blade Replacement and Cleaning: Regular inspection and replacement of blades are necessary to maintain cutting efficiency. Clearing debris from the header helps prevent corrosion and extends the equipment’s lifespan.

- Lubrication Maintenance: Moving parts require periodic lubrication to keep operations smooth and reduce wear from excessive friction.

- Fuel Consumption: Combine harvesters consume a significant amount of diesel or other fuel, so daily fuel costs should be factored into operational expenses.

Curious About the Latest in Combine Harvester Technology? Future Trends Unveiled

- Autonomous and Driverless Harvesters: Explore how autonomous driving technology is opening up new possibilities for agriculture, even enabling intelligent harvesting with no operator required.

- Data Analytics and Precision Agriculture: Discover how modern harvesters use sensors and data analysis to enhance precision, making every acre of land more productive.

- Electric and Eco-Friendly Technologies: See how new combine harvesters are adopting environmentally friendly technologies to reduce carbon emissions and improve energy efficiency.

Conclusion

Combine harvesters are not just efficient tools for modern agriculture; they’re innovative machines that boost productivity and lighten the workload. Whether you own a large farm or manage a smaller operation, learning about and using a combine harvester can make your harvest season more enjoyable and less demanding. To explore different types of combine harvesters and stay updated on the latest technology, visit Minnuo Group’s website. We are pleased to offer professional advice and support. Connect with us, and let us help you find the perfect equipment!