In recent years, tropical and subtropical agriculture has expanded significantly, particularly in regions like Southeast Asia, Southern China, and Brazil. These zones contribute heavily to global food production but face unique environmental challenges due to their climate. Unlike temperate zones, farms in these areas deal with consistently high humidity, dense vegetation, and frequent monsoon rains and able to maintain agricultural machinery—conditions that push agricultural equipment to its operational limits.

In such climates, farmers often ask: “Why do my machines rust so fast?” or “Why do electronics fail after only one rainy season?” The answer lies in moisture exposure. Persistent rainfall leads to standing water and muddy terrain, while high ambient humidity accelerates corrosion and causes moisture infiltration into sensitive components. Without targeted solutions, machines in wet zones suffer from shortened service life, unstable performance, and unexpected downtime.

This article provides practical guidance on how to adapt and maintain agricultural machinery in wet and flooded field conditions. From waterproofing electronics to rustproofing the chassis, and from grease selection to tire maintenance—we’ll walk you through climate-smart solutions that prevent costly failures and protect your equipment investment. Read on to ensure your machinery thrives even in the wettest environments.

Contents

- 1 I. Key Environmental Challenges in Wet and Humid Zones

- 1.1 1. High Rainfall Frequency: Persistent Waterlogging, Muddy Operational Yards

- 1.2 2. Humidity > 75% Year-Round: equipment in a condensing environment for a long time

- 1.3 3. Soil Adhesion: Wetland soil is sticky and the undercarriage is easy to be clogged.

- 1.4 4. Electrical Hazards: Water vapor penetrates into the control system, inducing malfunctions

- 1.5 5. Biological Growth: Mold and algae can easily grow on the surface of the body and filter element

- 2 II. Waterproofing the Electrical System: Protecting the electrical system from moisture intrusion

- 2.1 1. Cable and connector waterproof upgrade: external waterproof + internal sealing dual solution

- 2.2 2. ECU and fuse box sealing treatment: high-value module key protection

- 2.3 3. Sensor protection measures: against water spray and electrolytic corrosion

- 2.4 4. Active Detection and Intelligent Protection Expansion

- 3 III. Anti-Rust and Corrosion Protection for Chassis and Undercarriage

- 3.1 1. Surface anti-corrosion enhancement: active anti-oxidation, inhibiting rust and corrosion from the source

- 3.2 2. Chassis structural design optimization: channeling drainage, reducing fluid retention

- 3.3 3. High-frequency cleaning process after rain: mud and water + corrosion dual risk must be removed.

- 3.4 4. Recommendations for anti-corrosion consumables and equipment matching reference

- 4 IV. Lubrication and Oil Management in High-Humidity Environments

- 4.1 1. Moisture invasion mechanism and impact analysis

- 4.2 2. Recommended oil/grease configuration: “waterproof” as the preferred standard.

- 4.3 3. Suggestions on moisture-proof components and oil protection structure

- 4.4 4. Suggestions for optimizing daily inspection and replacement cycle

- 4.5 5. Extension recommendations and emergency response

- 5 V. Tire and Track Maintenance in Wet Terrains

- 6 ❓ Frequently Asked Questions (FAQ):

- 7 What MINNUO Global Users Say

- 8 Conclusion

I. Key Environmental Challenges in Wet and Humid Zones

Agricultural equipment faces complex climate and soil challenges in wet and rainy environments, and these factors can have a direct impact on equipment operational stability, maintenance frequency, and life cycle. Here are five typical problems and their deeper impacts:

1. High Rainfall Frequency: Persistent Waterlogging, Muddy Operational Yards

Prolonged waterlogging in the field makes tractors and harvesters susceptible to bogging down, skidding, and bottoming out.

High soil moisture content causes tires to get stuck in the mud or the chain track chassis to get wet for a long time.

It is easy to form “swampy field” operating conditions, intensifying the test of the chassis structure and power output system.

✅ Extension of the problem: Poorly drained areas especially require reinforced chassis guards and seals to minimize mud erosion.

2. Humidity > 75% Year-Round: equipment in a condensing environment for a long time

Body steel structure, connectors, electrical terminal boards, etc. are often condensed, and the metal is easy to oxidize.

Poorly ventilated parts (such as the bottom of the cockpit, control box, fuel tank cover) form a miniature wet zone, inducing rust and corrosion.

Some plastic and rubber parts age faster and lose elasticity under long-term humidity.

✅ Engineering Suggestion: All electronic control systems should be equipped with anti-condensation seals, and materials with good moisture resistance and hydrolysis resistance should be selected.

3. Soil Adhesion: Wetland soil is sticky and the undercarriage is easy to be clogged.

The soil has strong adhesion, and it is easy to form “sticky mud shell” on the wheel hub, brake disk and track after operation.

It is easy to lead to the rise of operational resistance, fuel consumption, and uneven wear and tear of chassis transmission parts.

If not cleaned in time, hardened blocks will be formed after drying, which may damage the oil seal or drive shaft.

✅ Maintenance Points: High-pressure rinsing of the chassis must be carried out after each operation to avoid sediment residue caking.

4. Electrical Hazards: Water vapor penetrates into the control system, inducing malfunctions

If the plug and socket are not sealed properly, it is very easy for water to enter and short-circuit.

Control board circuit board exposed area, rising moisture leads to PCB mold or corrosion.

Battery connection port resistance rises in foggy weather, starting difficulties are frequent.

✅ Suggested Configuration: All key electrical parts should be IP67 rated, with waterproof breathable membrane and double locking connectors are recommended.

5. Biological Growth: Mold and algae can easily grow on the surface of the body and filter element

When the unit is parked for a long period of time, water and algae can easily accumulate in the crevices of the body and the air filter housing.

If water vapor is deposited in the diesel fuel tank, it is easy to breed microorganisms, corrode the fuel line and clog the nozzle.

Seats and sponge soft packages that are damp and moldy will affect driving comfort and air health.

✅ Practical reminder: It is recommended to park the equipment in a ventilated and rain-shielded place during non-operating seasons, and replace the desiccant or turn on the dehumidifying fan regularly.

II. Waterproofing the Electrical System: Protecting the electrical system from moisture intrusion

Under wet or paddy field operating conditions, the electrical systems of farm machinery are highly susceptible to short circuits, false alarms, and sensor failures. Especially after thunderstorms, accidents such as equipment startup failure and circuit board burnout are frequent. In order to ensure the long-term operation and stability of the electronic system in high humidity environment, it is necessary to strengthen the waterproof from the cable, connector, main control system to the sensor.

1. Cable and connector waterproof upgrade: external waterproof + internal sealing dual solution

Recommended cable material: the use of temperature ≥ 105 ° C, hydrolysis-resistant, UV-resistant marine-grade silicone cable.

Recommendations for critical joints: All plugs/connectors should be upgraded to IP67/IP69K protection level with the following treatments:

Dual-locking structure: Ensure stable connection and avoid loosening caused by moisture and vibration;

Heat-shrinkable tubing tightening wrapping: Heating and sealing at the ports to prevent moisture from seeping in;

Installation of corrugated tubing + hot-melt adhesive plugging on the cable outlets to enhance the mechanical protection capability.

✅ Suggestion: Sensing cables exposed to mud and water (e.g. rear axle, chassis, hitch) should be wrapped with “soft sleeve + water-resistant adhesive”.

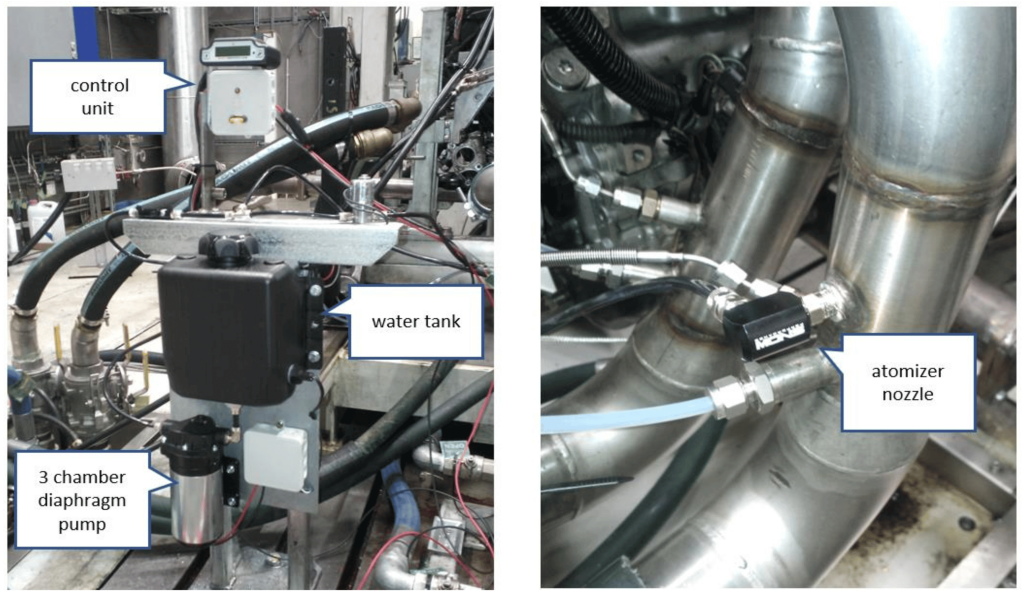

2. ECU and fuse box sealing treatment: high-value module key protection

sealing method recommended:

use EPDM with elastic memory, water and temperature resistance;

for the fuse box circuit board, it is recommended to use the whole epoxy resin potting or electronic moisture spraying (three-proof paint);

shell should be selected corrosion-resistant and high-tensile plastic materials (such as ABS + fiberglass or PC + PBT), with a drainage groove design. Drainage groove design.

✅ Key Note: ECU (Electronic Control Unit) once the water, maintenance costs are extremely high, it is recommended that the selection of priority consideration of the “original potting type” or with an independent airtight chamber of the module.

3. Sensor protection measures: against water spray and electrolytic corrosion

All pressure sensors, temperature sensors, level probes, etc. should be equipped with:

Breathable waterproof membrane (ePTFE): to prevent the accumulation of internal moisture and balance the pressure;

Waterproof cap or shroud with screen: to block the splashing of mud and water, to protect the sensor membrane surface intact;

Silicone sealing ring + anti-loosening shrapnel design of the connecting position, to avoid the loosening of the water intake.

✅ Special Note: After rain or continuous low temperature and high humidity operation, most of the sensor data abnormalities are caused by “pin water vapor oxidation”.

4. Active Detection and Intelligent Protection Expansion

In complex wetland operation, it is recommended to add an “active alarm” mechanism to the key circuit:

Install Water-In-Connector Sensor;

The use of an intelligent fuse box with “leakage detection + rising joint resistance alert”;

can be equipped with an optional “24V electrical system isolation protection module”, which can automatically disconnect the main power supply in case of abnormal humidity or short-circuit conditions, preventing the system from expanding and damaging.

✅ MINNUO platform has supported electrical humidity abnormality reporting + fault code pop-up, which is convenient for remote diagnosis and maintenance management.

III. Anti-Rust and Corrosion Protection for Chassis and Undercarriage

Wet and rainy climates are the toughest corrosion test for farm machinery chassis structures. The frame, tracks, suspension arms, steering hinges and other areas are immersed in mud and water for a long period of time, with soil attached, which is very easy to cause the coating to fall off, rust and perforation, and mechanical malfunction. In order to realize “no rust and corrosion for the whole season”, it is necessary to build a full-process protection in three aspects: surface treatment, structural design and daily flushing.

1. Surface anti-corrosion enhancement: active anti-oxidation, inhibiting rust and corrosion from the source

Chassis steel parts are recommended to adopt:

three-layer electrophoretic anti-corrosion coating (primer + intermediate paint + topcoat), with a salt spray resistance of more than 500 hours;

pre-galvanized steel plate (thickness ≥ 40μm) is suitable for areas prone to contact with stagnant water such as footrests and inner wheel covers;

Optional epoxy-based “Rust Conversion Primer” for localized touch-ups during repairs to reduce the repeated spread of old rust.

✅ Note: Avoid using bare metal or untreated welding points exposed to humid environment, and sealing treatment should be done.

2. Chassis structural design optimization: channeling drainage, reducing fluid retention

Recommended modification points:

Setting up slanting drainage holes: enhancing gravity diversion, avoiding water stagnation in the corners of the beams;

Adding silicone sealing plugs on the wire harness/air hose outlets: preventing the phenomenon of “water entering into the tank along the wires”;

Designing sludge discharging slopes on the rotating shaft/supporting surfaces: sludge slides down automatically after operation, reducing the frequency of manual flushing.

✅ Typical case: some wetland tractor adopts the combination design of “V-type water separating plate + inverted cone mud hole”, which reduces the time of water accumulation by 60%.

3. High-frequency cleaning process after rain: mud and water + corrosion dual risk must be removed.

Key points of cleaning after operation:

Flushing key parts: track edge, brake pad housing, inner rim, bottom of hydraulic oil tank;

High-pressure water gun is recommended to use fan-shaped nozzle (45°), to clear the blind area of silt more thoroughly;

Blow-drying + ventilation after cleaning, to avoid “going into the warehouse before drying” leading to water vapor infiltration of steel. “Blow-dry + ventilate after cleaning to avoid water vapor penetration of steel parts;

Conduct monthly inspections of the chassis for a complete anti-rust coating, and re-spray with a fast-drying rust converter paint if necessary.

Additional recommendation: install paint adhesion stickers to determine whether the surface coating is blistering/flaking.

4. Recommendations for anti-corrosion consumables and equipment matching reference

| Protection position | Recommended Consumables | Description |

| Rims + bottom beams | Triple Anti Electrophoresis Primer | Resistant to acid rain, salt spray, strong adhesion |

| Hinges + axle ends | Black Cold Galvanizing Spray | Highly restorative, suitable for top-up spraying maintenance |

| Welded seams / dead ends | Thick Film Anti Rust Wax | Good penetration and sealing effect |

| Surface coverage | Waterborne Clear Sealer | Suitable for high humidity period in rainy season, anti-secondary oxidization |

IV. Lubrication and Oil Management in High-Humidity Environments

In high humidity environments, the biggest risk to the lubrication system is not insufficient lubrication, but “emulsification failure due to water intrusion”. Once the grease absorbs moisture and expands, or the hydraulic oil becomes muddy due to water emulsification, the lubrication will be poor and the noise will be frequent, and the gears will slip, the bearings will erode, and the motor will drag the cylinder. Therefore, the lubrication maintenance strategy in wet area should start from “waterproof and moisture absorption + grease replacement + condition monitoring”.

1. Moisture invasion mechanism and impact analysis

Moisture path:

Moisture infiltration into oil tank, gear box and hydraulic pipeline after rain or during operation;

Moisture brought in by outside air through breathing hole or refueling port;

Lubrication point is not sealed properly, and the bearing “absorbs moisture and condenses” at high temperature, which leads to oil-water mixing.

Impact performance:

oil white, cloudy: the most intuitive characteristics of emulsification;

bearing noise, lubrication failure, oil film rupture wear increased;

moisture accelerate the oxidation of lubricants, reduce the extreme pressure anti-wear performance, loss of protective effect.

✅ Typical problem case: some users do not replace the emulsified hydraulic oil in time for operation in rainy areas, resulting in hydraulic cylinder rod corrosion, pump rattling, and maintenance costs of thousands of dollars.

2. Recommended oil/grease configuration: “waterproof” as the preferred standard.

| Description | Recommended Lubricants | Characteristics |

| Resistant to acid rain, salt spray, strong adhesion | Calcium Sulfonate Complex Grease | Extremely strong resistance to water showers, not easy to emulsify, strong adhesion |

| Highly restorative, suitable for top-up spraying maintenance | Aluminum Complex Grease (with polymer) | Good viscosity, can maintain the oil film in wet conditions |

| Good penetration and sealing effect | Anti Emulsification Hydraulic Fluid (HL Series) | High temperature stability, containing waterproof surfactants |

| Suitable for high humidity period in rainy season, anti-secondary oxidization | PAO Fully Synthetic Grease (NLGI 1~2) | High-temperature humidity, suitable for small motors and high speed environments |

✅ Practical suggestions: It is recommended to adopt the “color-coded grease management method”, different parts of the standard with different colors of grease, to avoid cross-contamination.

3. Suggestions on moisture-proof components and oil protection structure

Recommended installation parts:

Desiccant Breather: installed in hydraulic oil tank and reducer oil tank, which can absorb moisture in the air and prevent moist air from entering with breathing;

Silicone drying cap added to the oil injection port: replacing the common ventilating cap, suitable for rainy season/watershed area;

Tank level observation mirror with cover: preventing rain from backflow;

Installation of oil condition monitoring stick: can detect metal debris, moisture indicator and viscosity.

4. Suggestions for optimizing daily inspection and replacement cycle

Hydraulic oil replacement frequency: shorten from 500 hours to 300~400 hours;

Grease replenishment frequency: re-grease every 80~120 hours or check the color change;

Condition determination method:

If the oil is milky white, with many bubbles, and astringent to the touch, it should be replaced immediately;

You can put a drop of it on a white paper, if the oozing ring is transparent and the edges are cloudy, it means that water is intruding;

After rainy season or muddy water operation: It is recommended to change the grease within 24 hours after operation or use a dry oiler for refilling.

5. Extension recommendations and emergency response

Site recommendations: in the rice area or South Asian wet environment, the establishment of a “dry area grease filling area”, to avoid direct maintenance of the equipment in the wet mud;

Emergency response:

If you find the bearing abnormal noise but can not replace the grease for the time being, it is recommended to use the “spray water replacement lubricant” temporary lubrication;

can be equipped with mobile lubrication pump truck for centralized lubrication.

V. Tire and Track Maintenance in Wet Terrains

In muddy, wet environments, farm equipment faces extreme ground adhesion challenges. Problems such as tire skidding, mud piling up on tracks, water ingress into bearings, and clogged treads occur frequently, which not only affects operational efficiency, but also may lead to power loss and safety risks. Therefore, the anti-mud and anti-skid capability of tires and tracks is an important guarantee for the reliability of agricultural machinery in wetland operation.

1. Preferred structure: Adapt to the wheel and track configuration of “soft ground + wet ground”.

| Type | Recommended Configurations | Advantages |

| Wide Body Floating Tire | M+S Grade (Mud+Snow) Tread + Deepening Tread | Increase grounding area, spread pressure, reduce the risk of trapping |

| Rubber Track System | Dual Wire Skeleton + Tread Depth Ratio ≥ 50% | Strong anti-sagging ability, suitable for paddy fields / puddle hills |

| Low Pressure Tire Configuration | Supports 0.5~0.8bar Tire Pressure Adjustment | Reduce the risk of compacted soil, improve the passing rate of soft soil |

✅ Tip: Adopting tires with “herringbone” or “herringbone” design of tread blocks can help to quickly shake off mud and reduce blockage.

2. Suggestions for anti-skid and mud removal measures

Mud adhesion reduces traction and increases energy consumption, and reasonable anti-mud configurations are key to improving performance.

Anti-slip measures:

Install tire pressure automatic adjustment system (TPMS+electronic control regulator): automatically raise and lower the tire pressure according to the load and terrain;

Adopt rubber compound with high grip coefficient: improve the rubber adhesion in wet environment;

Equip the crawler with embedded steel bone+beveled tooth structure: enhance traction and slow down the slippage.

Mud removal means:

Silicone release agent or oil-based mold release spray on tire sidewalls: to prevent mud from adhering and caking;

Graphite oil on rims: to reduce corrosion of mud and water and hardening of mud;

Removable “mud scraper” and “track sweeping shrapnel” are installed.

3. Maintenance and inspection recommendations

Tires and tracks are not “high-frequency failure points”, but they are “invisible consumables” in wet areas. Timely inspection and predictive maintenance is the key to ensure long-term operation.

Recommended frequency and content:

| Inspection Items | Recommended Frequency | Highlights |

| Tread Cracks, Deformation | Weekly | Bubbles, cracks, deep scratches |

| Track Wear and Tension | Every 100 hours | Asymmetric wear, loose teeth |

| Rim Bearing Water | After each operation | Puffing, ball slipping |

| Tread Cleaning | After each operation | Completely clogged with wet mud, need to be removed |

| Tire Pressure Adjustment | Before operation | Low/high pressure mode adapted to ground conditions |

✅ Practical advice: In long-term field operations, the grounded part of the tire can be lined with moisture-proof wooden boards or set up a “track walking cover” to avoid water and grass erosion of the rim.

Recommended Maintenance Schedule for Humid Areas

| Task | Recommended Frequency |

| Electrical connector check | Weekly |

| Mud rinse (undercarriage) | After every operation |

| Oil emulsification inspection | Every 100–150 hours |

| Grease replacement | Every 300–400 hours |

| Surface rust retouching | Monthly |

❓ Frequently Asked Questions (FAQ):

Q1: Are MINNUO machines suitable for long-term use in high-humidity environments like tropical regions?

A: Yes. MINNUO equipment is specially engineered with IP67/IP69K waterproof electrical systems, rust-proof chassis coatings, and moisture-resistant lubrication systems. They are field-tested in Southeast Asia, West Africa, and South America for year-round wet farming.

Q2: Will the chassis and undercarriage rust if I work in flooded paddy fields?

A: No, if maintained properly. MINNUO machines use triple-layer electrophoretic coating and sealed cable ports to prevent rust. Just rinse off mud and clear drainage holes after daily use.

Q3: How does MINNUO help reduce electrical faults in rainy conditions?

A: Our machines use marine-grade silicone sealing, waterproof gaskets, and sensor membranes. Optional “water-in-connector” detection alerts can notify users of early-stage moisture risks.

Q4: Can I adjust tire performance for muddy terrain?

A: Yes. Many MINNUO models support tire pressure adjustment systems and deep-tread flotation tires or rubber tracks. Silicone coatings are applied to resist mud adhesion and slippage.

Q5: What’s the recommended maintenance cycle in humid climates?

A: We suggest checking air filters every 50 hours, replacing grease every 300–400 hours, and inspecting tires and electrical plugs weekly. Use desiccant breathers and moisture-resistant grease where possible.

Q6: Do you offer support for flooded field operations in my country?

A: Yes. MINNUO supplies tailored regional configurations and has worked with farms in the Philippines, Indonesia, Nigeria, Brazil, and Thailand. Contact us to customize your setup for your local conditions.

What MINNUO Global Users Say

Indonesia | Mr. Rahmat, Rice Grower, Java Island

“Before switching to MINNUO, our machines often stalled during the rainy season. Their paddy-type wheel and waterproof wiring saved us so much downtime. Even after 8 hours in the field, the undercarriage doesn’t clog like before. Very reliable in monsoon conditions.”

Brazil | Joao C., Soybean Farm Manager, Mato Grosso

“We farm on heavy clay, and wet ground used to destroy our bearings. The silicone-sealed hubs and rust-proof chassis from MINNUO made a big difference—maintenance dropped by 40%. We now order with their moisture kits every time.”

Nigeria | Mrs. Adesuwa A., Cassava Producer, Delta State

“High humidity always gave us wiring and battery problems. Since upgrading to the MINNUO IP67 harness system, we’ve had zero short circuits—even during flooding. Plus, the remote water-in-connector warning helps our team act early.”

Philippines | Leo M., Cooperative Technician, Luzon

“We work in muddy lowlands. The smart pressure-adjustable tires and de-mud features of the MINNUO tractors work better than expected. We no longer worry about being stuck or damaging tires mid-season.”

Thailand | Kittisak S., Rice + Fruit Grower, Chiang Rai

“The chassis coating is excellent—after a full year of wet work, no rust. That’s rare. We also like the onboard reminders for greasing. Makes daily maintenance easy even for new workers.”

Conclusion

Farming in flooded fields doesn’t have to mean faster machine breakdowns. With the right preventive measures—such as sealing electrical systems, rustproofing chassis components, and managing lubricant exposure to moisture—you can maintain stable performance even under year-round wet and muddy conditions.

MINNUO understands the real-world challenges of operating in high-rainfall zones. That’s why we provide agricultural machinery built with climate-adaptive designs: from waterproof electrical connectors to rust-resistant undercarriages and hydrophobic grease systems. Whether you’re working in tropical rice paddies or waterlogged lowlands, MINNUO helps you reduce downtime and keep your operation running—rain or shine.