Global climate change is quietly altering the pattern of agricultural production. In some areas, the rainy season has significantly lengthened, and waterlogging in farmlands has become increasingly frequent. For farmers who rely on agricultural machinery for operations, damp, muddy or even waterlogged fields have become the “invisible killers” of their equipment – problems such as electrical system short circuits, metal rust on the chassis, and water ingress and jamming of bearings are common. These not only affect the current operation progress but also significantly shorten the lifespan of maintain agricultural machinery and increase the cost of later maintenance.

Focusing on the core issue of “how to maintain machinery in wet conditions during paddy field cultivation”, the focus is on the key links where machinery is prone to damage in paddy field environments, such as how to prevent electrical equipment from getting wet and short-circuiting in muddy and waterlogged areas to ensure the stable operation of the circuit system. How to prevent the mud and water in paddy fields from rusting the mechanical chassis and extend its service life; In a humid environment, how to maintain transmission bearings, hydraulic devices, etc. to prevent them from malfunctioning due to water ingress or moisture.

This article is specifically designed for farmers facing such predicaments. It systematically sorts out the usage skills and maintenance points of agricultural machinery in rainy and humid environments, providing comprehensive practical solutions from the electrical system to the engine, from daily maintenance to equipment upgrades. It helps you minimize the damage of the environment to agricultural machinery and ensures that each piece of equipment can maintain a stable and efficient operating state under complex working conditions.

Contents

Electrical system

The electrical system of agricultural machinery is the most vulnerable part in a humid environment. Even a trace amount of water vapor intrusion may cause a short circuit fault. To ensure that circuits can “safely get through the flood season”, efforts should be made from three dimensions: sealing, protection and management.

Before each operation, carefully inspect the electrical interfaces for sealing and insulation checks: whether the sensor plugs are properly fitted with waterproof rubber sleeves, whether the sealing rings at the wiring harness joints are aged or cracked, and whether there are any water seepage marks at the joints between the instrument panel and the operation console. For lamps that are frequently exposed, it is necessary to confirm whether the lampshade is intact and whether the waterproof rubber ring of the bulb base is tightly attached. Once the seal is found to be damaged, it should be replaced immediately. Do not take the chance of “making do temporarily”.

Waterproof reinforcement of key components is equally important. Precision circuit components such as engine control modules and solenoid valves can be sprayed with professional electronic waterproof coatings – these coatings can form a micron-level protective film, which not only does not affect the heat dissipation of the components but also isolates water vapor and dust. For the gaps in the motor housing, silicone rubber sealant can be applied. After curing, it will form an elastic waterproof barrier. It should be noted that before spraying or applying, it is necessary to ensure that the surface of the component is clean and dry; otherwise, it will affect the protective effect.

The management of batteries and wiring harnesses involves a lot of knowledge. If agricultural machinery often operates in waterlogged fields, the battery position can be raised by installing brackets to be 10 to 15 centimeters away from areas where water may splash. The battery terminals should be coated with Vaseline or special anti-corrosion paste to prevent oxidation and rusting. When fixing the wiring harness, it is necessary to avoid it hanging low and dragging on the ground. Waterproof corrugated tubes can be used to wrap the exposed parts, and heat shrink tubes can be used to seal the joints. At the same time, when wiring, keep it away from high-temperature components such as exhaust pipes to prevent the aging of protective materials.

Post-assignment inspection and handling are indispensable. After work every day, wipe the moisture off the surface of electrical components with a dry cloth, and pay special attention to checking whether the motor, controller and other parts are damp. If water condensation or soil is found on the surface of the component, it can be blown clean with compressed air and then dried at low temperature with an infrared lamp (keep a distance of more than 50 centimeters to avoid damage to the component due to high temperature). Before long-term parking, it is best to remove the battery and store it separately in a dry place. Recharge the battery once a month to prevent undercharging and sulfation of the plates.

Chassis and body

The chassis of agricultural machinery is constantly in contact with mud and water, and metal rust is like a “chronic disease”. It is not easy to detect in the early stage, but once it develops to a certain extent, it may lead to a decrease in component strength, loose connections, and even cause safety hazards. To do a good job in rust prevention, it is necessary to adopt a three-pronged approach of “cleaning + protection + storage”.

The selection and application of anti-rust materials should be adapted to local conditions. For load-bearing components such as the chassis crossbeam and suspension bracket, it is recommended to apply cold-sprayed zinc paint with a high zinc content. Its cathodic protection effect can slow down the rusting rate. Fasteners such as bolts and nuts can be treated with Dacromet coating. Compared with ordinary galvanizing, its salt spray resistance is improved by 3 to 5 times. For dead corners prone to water accumulation such as welding seams, anti-rust primer can be applied first, followed by elastic anti-rust paint. The flexibility of the paint film can be utilized to cover the tiny gaps. It should be noted that before using new agricultural machinery, it is best to carry out a comprehensive anti-rust strengthening treatment, which is equivalent to putting on a “protective armor” for the equipment.

The removal of mud and water after work is extremely urgent. Farmland slurry contains a large amount of humus and salt. Long-term adhesion will accelerate the corrosion of metals. After the daily work is completed, the chassis should be immediately rinsed with a high-pressure water gun, with a focus on cleaning the mud blocks on the inner side of the tires, mudguards, drive shaft guards and other parts. For the residual mud in the crevices, a hard-bristled brush combined with clean water can be used to scrub. If necessary, iron wire can be used to clear the blocked holes. After the cleaning is completed, let the agricultural machinery idle in a well-ventilated area for 10 to 15 minutes to use the engine heat to dry out the moisture and prevent condensation at night from aggravating rust.

The maintenance of drainage holes is often overlooked, but it directly affects the anti-rust effect. Drainage holes are usually provided on parts such as the chassis of agricultural machinery, the floor of the cab, and the toolbox. If they are blocked by soil or weeds, it will cause water to accumulate for a long time. All drainage holes should be inspected regularly every week. Use thin iron wire or a special unclogging tool to clear the blockages and ensure that the accumulated water can be discharged smoothly. Before the rainy season comes, a small amount of grease can be applied to the edge of the drainage holes to reduce the possibility of sediment adhering.

The choice of storage environment is crucial for rust prevention. When conditions permit, agricultural machinery should be parked in dry and well-ventilated sheds or warehouses, with crushed stones or wooden boards laid on the ground to avoid direct contact with moist soil. If it can only be stored outdoors, it should be completely covered with waterproof canvas. The hem of the canvas should be close to the ground and pressed down with a heavy object to prevent rainwater from seeping in. At the same time, place bricks under the tires to reduce the water exchange between the tires and the ground. Before long-term storage, a thorough cleaning and anti-rust treatment should be carried out on the chassis. Apply anti-rust oil to the exposed metal surfaces and add grease to the moving joints to form a closed protective layer.

Transmission system and bearings

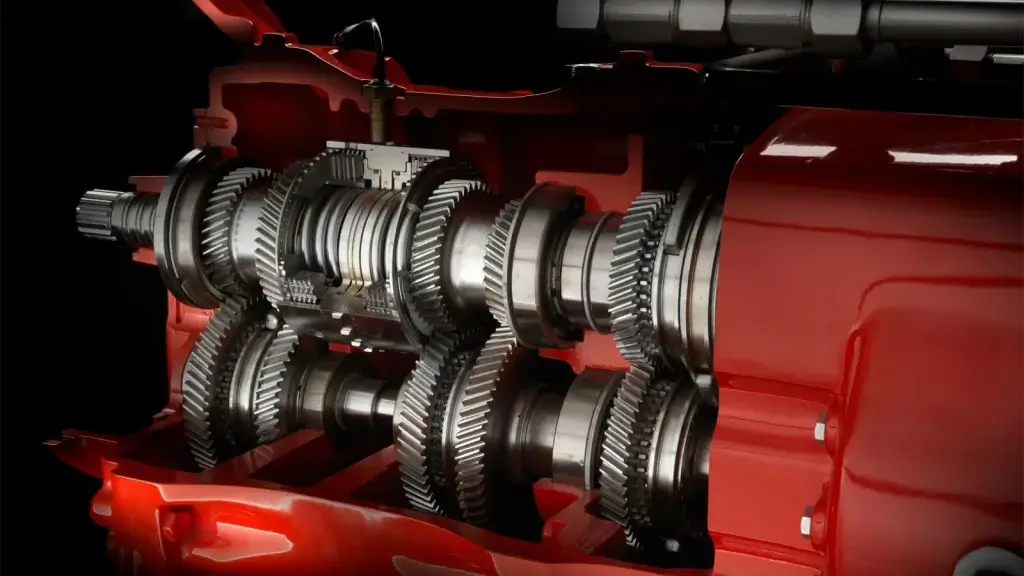

The transmission system is the “power link” of agricultural machinery. Once components such as bearings, gears and chains get wet, it will not only accelerate wear but also may cause jamming faults, directly affecting the operation efficiency. To ensure the waterproofing and protection of the transmission system, it is necessary to start from three aspects: seal inspection, lubrication and maintenance, and emergency response.

The integrity of the seal is the key to preventing water vapor from entering. Each time maintenance is carried out, carefully inspect the oil seal of the drive shaft, the sealing ring of the bearing, the gasket of the gearbox end cover and other sealing parts. If aging, cracking, deformation or other conditions are found, they should be replaced immediately. When replacing the sealing parts, ensure that the installation surface is clean and flat, apply special sealant (such as silicone sealant) to assist in sealing, and tighten the bolts evenly to the specified torque to avoid seal failure due to uneven force. For agricultural machinery that frequently operates in deep water fields, double-lip oil seals can be selected. Compared with ordinary single-lip oil seals, their waterproof performance has been significantly improved.

Lubrication and maintenance require “extra care” in a humid environment. The lubricating oil (grease) of the transmission components not only serves a lubricating function but also forms an oil film to prevent water vapor from entering. After each operation in muddy or waterlogged fields, the condition of the lubricating oil (grease) should be checked in a timely manner. If emulsification, turbidity or impurities are found, it should be replaced immediately. Under normal circumstances, the lubrication and maintenance cycle during the rainy season should be shortened by 30%. For instance, the gear oil that was originally replaced every 50 hours can be adjusted to be replaced every 35 hours. For exposed transmission components such as chains and sprockets, after operation, the dirt and old grease on the surface should be cleaned with kerosene. After drying, apply waterproof grease (such as lithium-based grease), and rotate the chain to ensure that the grease fully penetrates the gaps between the chain pins. The bearing area should be lubricated with grease using a high-pressure grease gun until new grease is squeezed out from the gaps, carrying out any water vapor and impurities that may exist inside.

The daily protection of transmission components can effectively reduce the risk of water damage. The chain drive system can be equipped with a protective cover to prevent mud and water from directly splashing onto the chain during operation. The vent holes of the gearbox should be equipped with waterproof and breathable valves, which can not only balance the pressure inside and outside the box but also prevent rainwater from entering. For equipment with conveying chains such as harvesters and transplanters, water barriers can be installed above the chains to reduce direct erosion by rainwater and muddy water. During operation, if any abnormal sounds or jamming are detected in the transmission components, the machine should be stopped immediately for inspection to prevent the fault from worsening while it is faulty.

Emergency response to water ingress in bearings requires “racing against time”. If water seepage marks are found at the bearing area, or if abnormal noises or overheating occur during operation, it is very likely that the early failure is caused by water ingress. At this point, operations should be immediately halted and the bearings disassembled for inspection: First, clean the inner and outer rings, rollers and cages of the bearings with kerosene to remove moisture and impurities, and then dry them with compressed air. Check whether there is rust or scratches on the raceway and roller surfaces. If the damage is minor, apply anti-rust grease and reinstall. If the damage is severe, a new bearing must be replaced. When reassembling, the bearing housing hole must be clean and dry. The bearing should be heated to 80-100℃ before installation (in case of interference fit), ensuring a tight assembly. Finally, add grease as per regulations to restore the sealing state.

Engine and intake system

The engine is the “heart” of agricultural machinery. In a humid environment, problems such as water ingress, poor air intake, and fuel contamination can all lead to a decrease in power or even engine stalling. Protecting the engine and intake system is the core to ensuring the normal operation of agricultural machinery.

The protection of the air intake is the first line of defense against water entering the engine. The height design of the air intake of agricultural machinery should match the working environment. If it is often used in waterlogged fields, it is necessary to check whether the air intake is higher than the maximum water depth that may be encountered (it is generally recommended to be more than 50 centimeters above the ground). When necessary, the intake system can be modified to lengthen the intake pipe and extend the intake port to the top of the cab. At the same time, a waterproof and breathable cover can be installed at the end of the intake pipe, which can not only ensure the intake volume but also effectively block rain and water vapor. Before starting the operation, it is necessary to confirm whether the protective cover of the air inlet is intact to prevent weeds and mud water from entering the air passage.

The maintenance of air filters needs to be “doubled frequently” in a humid environment. The water vapor in the humid air will cause the air filter element to become damp, adsorb more dust and impurities, resulting in increased intake resistance and a decrease in engine power. During the rainy season, the cleaning or replacement cycle of air filters should be shortened, for example, from the original every 100 hours to every 50 hours. After each operation, it is necessary to check whether the filter element is damp or clogged. For paper filter elements, gently tap to remove surface dust. If it is damp, it must be replaced. Oil bath air filters need to have their engine oil changed regularly to keep the oil level at a normal level and enhance the filtering effect on wet dust. When installing the filter element, make sure the sealing gasket is intact and the filter element is closely attached to the housing to prevent unfiltered wet air from directly entering the engine.

The waterproof protection of the fuel system is equally crucial. If diesel is mixed with water, it will lead to problems such as poor combustion, clogged fuel injectors and worn fuel pumps. A waterproof cover with a vent hole should be installed at the fuel tank filling port. After each refueling, the cover should be tightened to prevent rainwater from seeping in. The drain valve at the bottom of the fuel tank should be opened once a week to discharge any accumulated water and impurities. For agricultural machinery that has been parked for a long time, the fuel tank should be filled to over 90% to reduce the volume of air inside the tank and lower the possibility of condensation water formation. At the same time, a water repellent for the fuel system can be added to help separate water from the fuel and prevent it from corroding metal parts.

The daily inspection of the engine should pay attention to the “water mark” signal. Before starting the engine every day, check the oil dipstick and the oil filler cap. If you find that the oil has emulsified and turned milky white, it is very likely caused by the mixture of coolant. You need to immediately check whether the cylinder block and cylinder head gaskets are damaged. Observe the exhaust gas discharged from the exhaust pipe. If there is a large amount of white smoke accompanied by water droplets, it may be that there is too much water in the fuel or water has entered the cylinder. The machine should be stopped for inspection. When working during the rainy season, if the engine suddenly stalls, do not restart it. First, check whether water has entered the air intake. After confirming that no water has entered, look for other causes to avoid forcing the start and causing secondary damage.

Hydraulic system and braking system

The hydraulic system is responsible for the execution of various actions of agricultural machinery, and the braking system is related to operation safety. In a humid environment, water intrusion and component rusting are the two major threats, and targeted protection and maintenance should be carried out.

The “anti-emulsification” of hydraulic oil is the core of hydraulic system maintenance. When water is mixed into the hydraulic oil, it will damage the integrity of the oil film, accelerate the wear of hydraulic components, and at the same time may cause emulsification of the oil, reducing the working efficiency of the hydraulic system. During the rainy season, the condition of the hydraulic oil should be checked once a month. Observe through the dipstick whether the oil is turbid, stratified or emulsified. If necessary, use a moisture detector for precise detection (if the moisture content exceeds 0.1%, it should be dealt with in time). If emulsification of the hydraulic oil is found, it should be replaced immediately. At the same time, the hydraulic oil tank, filter and pipelines should be cleaned to remove the remaining emulsified oil. When changing to new oil, choose hydraulic oil with good anti-emulsification performance (such as anti-wear hydraulic oil L-HM series), and install a filter device at the oil filling port to prevent water from mixing in during the filling process.

The sealing and protection of the hydraulic system cannot be ignored. The sealing parts of components such as hydraulic pumps, hydraulic cylinders and directional control valves need to be inspected regularly. If leakage is found, they should be replaced in time to prevent rainwater from entering the system through the leakage points. If the outer layer of the hydraulic hose ages and cracks, water vapor will seep into the reinforcing layer, accelerating the damage of the hose. It needs to be replaced in time. A waterproof sheath can be installed at the hose joint to reduce direct immersion in mud and water. For agricultural machinery that has been parked for a long time, the piston rod of the hydraulic cylinder should be retracted to the shortest position to ensure that the piston rod is fully protected by an oil seal. At the same time, operate each hydraulic handle to fill the entire system with hydraulic oil, creating a closed environment to prevent water vapor from entering.

Rust prevention and sensitivity maintenance of the braking system are of vital importance. In a humid environment, components such as brake discs, brake drums, and brake pads are prone to rust, which can lead to abnormal braking sounds, reduced braking performance, and even jamming. Before each operation, gently press the brake pedal several times to remove the floating rust on the surface of the brake disc through friction. After the operation, check if there is any mud or water adhering to the braking system. If so, rinse it clean with clear water, let it dry and then park it. The brake fluid level and condition should be checked weekly. If the brake fluid is cloudy or contains water, it must be completely replaced and vented. The joints of the brake lines must be well sealed to prevent rainwater from seeping in and causing internal rust. For drum brakes, the brake drum can be removed regularly to clean the mud and rust inside, check the wear of the brake shoes, and apply a small amount of special brake grease if necessary (note that it should not be applied to the friction plates).

Use and store scientifically

In a rainy and humid environment, the usage and parking management of agricultural machinery directly affect the rate of equipment wear and tear. Mastering scientific operation skills and storage methods can effectively reduce the damage caused by the environment to the equipment.

Adjusting the operation strategy can reduce the risk of equipment wear and tear. When working in fields with poor drainage, crawler agricultural machinery or wheeled agricultural machinery equipped with narrow tires should be given priority. Crawler equipment has a smaller ground contact pressure, and narrow tires can reduce soil compaction. Both can lower the probability of the vehicle getting stuck. Before starting the operation, it is necessary to investigate the water accumulation in the field and avoid deep water areas (areas with water depth exceeding the radius of the tires should not be entered). If it is necessary to pass through waterlogged sections, drive at a low speed and a constant speed to avoid sudden acceleration that may cause water splashes into the engine or electrical system. When turning in muddy fields, the steering amplitude should be reduced, and the steering handle should be operated slowly to prevent the tires from slipping and causing the steering mechanism to overload. When getting stuck in a vehicle, do not forcibly rev the accelerator. Instead, place hard objects such as wooden boards or stones to help you get out of the predicament and prevent the transmission system from being damaged due to overload.

The cleaning and drying process after work is indispensable. After each day’s work, in addition to cleaning the chassis and transmission components, it is also necessary to clean the interior of the cab: wipe the mud, water and moisture on the control console, seats and floor with a dry cloth, open the car doors and Windows for ventilation, and place dehumidification bags to absorb the moisture inside the vehicle if necessary. For components such as the grain box of the harvester and the seedling tray of the transplanter, it is necessary to empty the remaining crops and soil, rinse them clean with water and then dry them to prevent the residues from getting damp, moldy and corroding the equipment. After the cleaning is completed, park the agricultural machinery in a well-ventilated area, let the engine idle for 5 to 10 minutes to allow the temperature of each component to rise and evaporate water vapor. At the same time, turn all the operation handles to ensure that the moving parts of the hydraulic system and braking system are fully lubricated, reducing the possibility of condensation and rusting at night.

The regular maintenance cycle needs to be “flexibly adjusted” during the rainy season. A humid environment will accelerate the deterioration of lubricating oil (grease) and the aging of seals. Therefore, the maintenance cycle should be appropriately shortened according to the environmental humidity and operation intensity. For instance, a comprehensive maintenance that is usually carried out once every quarter can be adjusted to once a month during the rainy season. The replacement cycle of the air filter and fuel filter has been shortened by 50%. The replacement cycle of hydraulic oil and gear oil has been shortened by 30%. Each time maintenance is carried out, all lubrication points should be filled, the electrical system should be inspected for water resistance, and the metal parts should be treated for rust prevention to ensure that the equipment is always in good condition.

Upgrading and purchasing of agricultural machinery

For farmers who often work in rainy and humid environments, choosing agricultural machinery with good waterproof and rust-proof designs or upgrading existing equipment in a targeted manner can fundamentally reduce maintenance costs and enhance operational reliability.

Key considerations for “waterproofing and rust prevention” when purchasing agricultural machinery. When purchasing new agricultural machinery, it is necessary to give priority to checking the protection level of the equipment: the electrical system should meet the IP67 or above protection standard (completely preventing dust from entering and no damage after short-term immersion in water), and the protection level of key components (such as engines and hydraulic pumps) should also be given special attention. Rust prevention treatment of the chassis and transmission system is a key point. Ask the manufacturer whether they adopt processes such as overall galvanizing and electrophoretic painting. Compared with ordinary painting, these processes have a more lasting rust prevention effect. Check the sealing design: Whether the engine air intake has a waterproof diversion structure, whether the electrical interfaces use waterproof plugs, and whether the hydraulic pipeline joints have double seals. These details directly determine the moisture resistance performance of the equipment. In addition, models equipped with intelligent monitoring systems can be selected. Such devices can monitor parameters such as engine water temperature, hydraulic oil status, and component temperature in real time, and promptly warn of risks of faults such as water ingress and overheating.

The upgrading and transformation plan for the existing agricultural machinery. For agricultural machinery that needs to operate in deep water fields, water-wading kits can be installed, including lengthening the air intake pipe, raising the position of the electrical control module, and replacing lamps with higher waterproof grades, etc. The chassis and exposed metal parts can undergo secondary anti-rust treatment, such as spraying polyurea coating, whose wear resistance and corrosion resistance far exceed those of ordinary anti-rust paint. Fasteners such as bolts and nuts can be replaced with stainless steel to avoid difficulty in disassembly after rusting. The hydraulic system can be equipped with a moisture sensor. When it detects that the moisture content in the oil exceeds the standard, it will alarm in time. The electrical system can be equipped with a waterproof relay box to centrally protect vulnerable relays and fuses, reducing short-circuit faults.

The input-output ratio of upgrading and protection is worth paying attention to. Although upgrading to waterproofing and rust prevention requires certain investment (for instance, a set of water-wading kits costs about several thousand yuan, and a full vehicle rust prevention treatment costs around a thousand yuan), in the long run, it can significantly reduce maintenance costs. According to statistics, compared with unprotected agricultural machinery, well-protected agricultural machinery can reduce the average annual maintenance cost by 40% to 60% and extend its service life by 3 to 5 years. For instance, a tractor worth 100,000 yuan, if scrapped two years ahead of schedule due to rust, incurs a loss of approximately 40,000 yuan. However, by investing several hundred yuan in protection costs each year, such losses can be effectively avoided. Therefore, it is a highly cost-effective investment to carry out appropriate protective upgrades in the first three years of agricultural machinery use.

Conclusion

In the rainy and humid farmland environment, every malfunction of agricultural machinery may miss the best working opportunity, and every major overhaul means considerable economic losses. Proper waterproofing, rust prevention and daily maintenance of agricultural machinery not only protect the equipment but also ensure the efficiency of agricultural production.

From the sealing protection of the electrical system to the anti-rust treatment of the chassis, from the lubrication and maintenance of the transmission components to the prevention of water ingress in the engine, every detail of maintenance is contributing to the stable operation of agricultural machinery. Farmers should develop the good habit of “checking before operation, cleaning after operation and regular maintenance”, and adjust maintenance strategies in a timely manner according to environmental changes to keep agricultural machinery always in a “healthy state”.

Remember, a well-maintained agricultural machine can not only handle the fields with ease during the rainy season, but also bring you continuous and stable productivity, ensuring that every bit of hard work yields the due rewards. Maintaining agricultural machinery is safeguarding your harvest and your economic benefits.