Against the backdrop of global energy shortages and the green transformation of agriculture, energy has become a critical factor limiting the sustainable operation and cost control of farms. In recent years, agricultural energy expenditures have risen significantly, with farms facing risks such as volatile energy prices, unstable power supply, and difficulties in accessing diesel. At the same time, there is growing pressure to manage carbon emissions and meet farm green certification standards. These challenges are prompting more and more farmers to ask: Is it possible to achieve an internal, self-sustaining energy cycle to reduce reliance on traditional energy sources?

Promoting energy self-sufficiency in agriculture is not only a pragmatic choice to relieve cost pressures, but also a core pathway to achieving sustainable agricultural development. By building “zero-carbon farms” and “green farms” to reduce their carbon footprint, farmers can enhance production autonomy, ensure continuity of operations, and gain an early advantage in environmental policies and green consumer markets. This is especially vital for small and medium-sized farms, where the ability to generate and manage their own energy means more flexible operations, greater control over investments, and improved long-term profitability.

This article will systematically explore how to integrate solar power, biogas, and electric tractors to build an “energy self-sufficient farm.” The goal is to help farmers achieve energy independence, green production, and cost optimization in real-world operations. Whether you’re upgrading your farm machinery system, exploring emission reduction strategies, or seeking to improve energy efficiency, this article offers practical strategies and case-based insights tailored to your needs.

Contents

I. The Case for Energy Independence in Agriculture

1. The Impact of Energy Costs on Agricultural Operations

Agriculture is highly energy-dependent, especially in processes such as tilling, irrigation, harvesting, storage, and transportation. These operations consume significant amounts of fossil fuels like diesel and natural gas, which often account for a large portion of daily operating expenses—reaching 30% to 50% in machinery-intensive farms.

Typical scenarios include:

Greenhouses in winter rely on gas boilers for heating

Large agricultural machines consume dozens of liters of fuel per day

Remote areas face high logistics costs for fuel transportation

Conclusion: Even slight increases in energy prices can erode farm profitability, particularly for small-scale growers whose profit margins are already slim.

2. External Risks Expose the Fragility of Energy Dependence

Major risk factors include:

Price volatility: International energy markets have become increasingly unstable in recent years due to geopolitical events (e.g., the Russia–Ukraine conflict, OPEC production cuts), making agricultural energy costs difficult to forecast.

Unstable supply: Remote or rural areas often have underdeveloped energy infrastructure. Disruptions like road closures due to heavy rain or lockdowns during pandemics can prevent timely fuel delivery, halting machine operations.

Rising carbon regulation pressure: More countries and regions are incorporating agricultural carbon emissions into regulatory frameworks. This includes banning coal-fired boilers, restricting diesel use, or implementing carbon-intensity-based taxation.

Therefore, building localized energy systems that are stable, controllable, and environmentally friendly has become a practical solution for mitigating external risks in agriculture.

3. Green Agricultural Transition: A Policy Direction and Market Trend

The future of farming is no longer just about “yield,” but about being green and low-carbon—a shift that is no longer just a slogan but an enforceable standard. Many governments are establishing green farm certification systems, carbon footprint labeling mechanisms, and offering incentives for adopting renewable energy technologies in agriculture.

Examples:

EU CAP Reform: Direct green subsidies are offered to support renewable energy investment in agriculture

China’s Ministry of Agriculture and Rural Affairs: Electrification of agricultural machinery is a key focus of the 14th Five-Year Plan

Consumer preferences: E-commerce platforms and supermarkets are increasingly promoting “zero-carbon food” and “green agricultural products,” creating premium pricing opportunities for sustainable goods

Extended Value

Energy self-sufficiency is not just about saving money—it reflects a farm’s autonomous control over its supply chain. With systems such as solar PV, biogas, and electric agricultural equipment, farms gain not only reliable internal energy sources, but also potential new revenue streams through grid feed-in tariffs and resource recycling.

II. Core Technologies for an Energy-Independent Farm

A truly energy-independent farm does not rely on a single energy source. Instead, it integrates solar power, biogas, and electric agricultural machinery into a complementary clean energy system. This enables a closed-loop energy cycle that powers everything from daily electricity use and machinery operations to greenhouse management.

1. Solar Energy System

Application Scenarios:

Power supply for residential areas (lighting, appliances, internet)

Energy for irrigation systems (pumps, automatic valve control)

Charging electric tractors, tools, electric fences, and other equipment

System Structure:

Distributed photovoltaic systems installed on rooftops, barn tops, greenhouse arches, parking sheds, or idle wall spaces

A complete loop includes solar panels + MPPT controller + energy storage battery + inverter

Energy Storage Options:

Lithium iron phosphate batteries or supercapacitors for day-and-night operation

Optional integration with micro wind turbines to form a hybrid “wind-solar complementary” system for cloudy or rainy days

✅ Key Advantages:

Zero emissions, noise-free, and supports year-round operation with storage

Eligible for feed-in tariffs through grid integration, improving ROI

Ideal for remote areas and off-grid farms

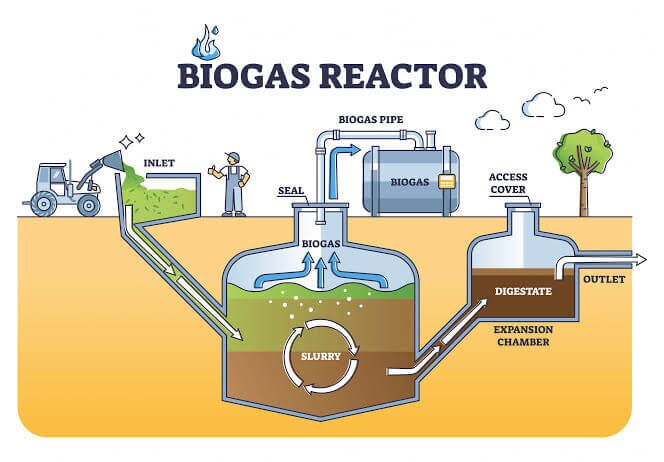

2. Biogas Energy System

Feedstock Sources:

Livestock manure, crop straw, fallen leaves, kitchen waste

Crop processing by-products like corn husks and vegetable trimmings

Application Methods:

Anaerobic digestion to produce methane gas for electricity, hot water, or heating

Digestate can be returned to fields as organic fertilizer, creating a closed resource loop

System Structure:

Anaerobic digesters, gas storage bags, purifiers, gas-water separators, pressure regulators, and combustion devices or micro-generators

Can be integrated into the farm’s electrical network or supply biogas boilers directly

✅ Key Advantages:

Converts waste into energy, saving on fuel and fertilizer expenses

Reduces environmental pollution from livestock waste

Contributes to green agriculture certifications or organic farming credentials

Typical Case:

A pig farm in Northern China uses waste from 100 pigs daily to fuel two hot water boilers and an irrigation pump system, saving nearly ¥20,000 annually on gas expenses.

3. Electric Tractor Systems

Types:

Fully electric small tractors: Ideal for greenhouses, nurseries, and small plots

Plug-in hybrid tractors: Suitable for medium-intensity power output tasks

Heavy-duty electric platform tractors (future focus): Support for autonomous driving and precision farming

Power Supply Options:

Direct DC fast charging from solar PV

Biogas generator-powered charging (connected to storage systems)

Battery storage using “off-peak night charging + daytime discharge”

Compatible Modules:

Plowing, seeding, fertilizing, transporting, spraying, weeding, harvesting arms, trailer platforms, etc.

Key Advantages:

Zero emissions and extremely low noise, ideal for operations near villages and homes

Electric drive systems have much lower maintenance costs than diesel engines (no engine wear, no oil required)

Supports intelligent upgrades such as remote monitoring, route automation, and load adjustment

Extended Value:

Farmers can access subsidies for green agricultural machinery and participate in “electric replaces diesel” incentive programs

Future integration with carbon trading systems to generate low-carbon revenue

System Integration Recommendations

| System Combination | Function Division | Operation Mode | Typical Scenario |

| Solar PV + Storage + Electric Machinery | Daytime field operations and irrigation systems | Stable all-day power supply | Regions with abundant sunlight or greenhouse zones |

| Biogas + Heat Storage + Electric Pumps | Nighttime/cloudy day power + winter heating | Night: biogas heating; Day: solar-assisted support | Livestock-crop integrated zones, northern climate areas |

| Solar PV + Biogas Grid Integration + Smart Scheduling | Dynamic-static energy mix with priority management | Multi-mode switching, data visualization, smart control | Medium-large ecological farms, rural industrial clusters |

III. System Integration: How These Technologies Work Together

To build a truly efficient and sustainable energy-independent farm, it’s not just about having solar power, biogas, and electric agricultural machinery. The key lies in system integration, where these components are coordinated and complement each other, enabling closed-loop energy use, operational efficiency, and controlled investment.

1. Farm Energy Flow Design

To adapt to varying weather conditions, time of day, and fluctuating farm loads, we recommend a “time-based coordination + dynamic-static energy complementarity” model:

| Time Period | Main Energy Source | Supporting System | Energy Use Targets |

| Sunny Daytime | Solar PV | Paired with storage or direct supply | Farm office, irrigation systems, fast charging for tractors |

| Night / Rainy Days | Biogas + Energy Storage | Power via biogas generation, hot water system | Backup power for tractors, greenhouse heating, household usage |

| Peak Operation Hours | Energy storage priority | EMS dynamic scheduling | High-load tractor operation, electric pumps |

| Off-Peak Hours | Auto low-power mode | Maintain basic farm energy use | Greenhouse temperature control, monitoring systems |

2. Digital Coordination + Energy Monitoring

To move from simply “usable” to “highly efficient” clean energy systems, a digital Energy Management System (EMS) is essential. Key functions include:

Energy Flow Monitoring: Real-time tracking of solar generation, biogas storage, battery levels, and machinery loads

Automated Dispatch Strategy: Intelligent switching based on load and energy source priority, ensuring uninterrupted supply

Energy Visualization: Displays each tractor’s charging consumption; supports carbon accounting and green certification

Remote Management: Farmers can monitor energy status, control scheduling, and receive alerts via mobile apps or web interfaces

Recommended Setup:

RTU (Remote Terminal Unit) + Smart Gateway + Cloud Platform

Visual Dashboards: Energy trend charts, generation comparisons, equipment health graphs

3. Why Integration Matters

Efficient Complementarity: Dynamic switching between energy sources ensures year-round, all-day stable power

Controlled Investment: Optimal energy allocation avoids redundancy and peak pricing spikes

Supports Carbon Management: Systematic tracking helps quantify emissions reductions and earn green policy subsidies

Adaptability: Flexible deployment for hilly terrain, greenhouses, or distributed family farms

Practical Tips

Prioritize Solar + Storage: Combine with electric tractors to immediately reduce fuel costs

Gradually Introduce Biogas: Start from livestock-rich zones to process waste and generate energy simultaneously

Choose EMS-Compatible Machinery (e.g., MINNUO): Ensures future system expansion and integration

IV. Benefits of Energy-Independent Farming

The 5 Core Advantages of Building an Energy-Self-Sufficient Farm

In the modernization of agriculture, creating a self-sustaining energy system is more than just eco-conscious—it’s a strategic way to gain operational autonomy, production stability, and brand value. These five factors drive farmers to invest in energy independence:

1. Controllable Costs & Long-Term Savings

With diesel and electricity prices rising, energy expenses are climbing. By adopting solar PV, biogas generation, and electric machinery, farmers can:

Avoid uncertainties caused by market fluctuations

Reduce external energy purchases (ROI in 3–5 years)

Enjoy flexibility by producing and consuming energy on demand

Case: A family farm in Jiaxing, Zhejiang installed a 40kW PV system and two electric tractors, saving over ¥20,000 annually on fuel and achieving full payback in three years.

2. Meet Environmental Trends & Certification Standards

More agri-product platforms, e-commerce channels, and local policies emphasize green certifications and carbon transparency:

Biogas systems help earn green livestock or organic farming qualifications

PV + electric machinery setups support applications for “low-carbon farm pilots” or “green production bases”

✅ Pro Tip: With systematized energy records, farmers can apply for carbon credits, green subsidies, and environmental loans

3. Autonomous Scheduling Improves Farm Efficiency

Traditional farms often suffer from “waiting for diesel” or “sudden power cuts,” delaying crucial activities like sowing or harvesting. With energy independence, farmers can:

Adjust tractor operation schedules based on solar availability

Control pumps, fans, heaters autonomously, reducing labor strain

Maintain operations even under extreme weather conditions

Keyword: Agricultural Energy Load Shifting = Production Resilience + Time Control

4. Resource Recycling & Waste Reduction

Biogas systems transform waste into energy:

Manure + straw → Biogas → Heat / Electricity / Drying

Digestate → High-efficiency organic fertilizer returned to the fields

This promotes integrated crop-livestock systems and supports carbon peaking and neutrality in agriculture.

Practical Advice: Start biogas systems in livestock areas, then expand to crop zones for synergy.

V. Implementation Strategy and Considerations

Building an integrated system of solar + biogas + electric machinery requires not only hardware and technical support but also smart planning, phased rollout, cost analysis, and site matching. Here’s a structured roadmap:

Three-Step Deployment Plan:

Step 1: Preliminary Evaluation & Load Modeling

Assess daily energy usage across offices, living areas, irrigation, climate control, and equipment charging

Map electricity demand peaks/seasons via “load curve”

Estimate clean energy replacement ratio (start with 40%-70%)

Tools: Excel + usage logs / Smart plugs / Load analysis from solar vendors

Step 2: Install Solar + Storage + Interface Equipment

Recommended PV capacity = Daily consumption × 1.3

Battery storage = Daily use × 0.8–1, factoring night/rain coverage

Include inverter (DC–AC) + EMS data interface for compatibility

Add smart meters + cloud platform for later optimization

Step 3: Deploy Biogas and Electric Machinery (Phased)

Start with biogas systems in livestock areas; recycle digestate as fertilizer

Begin electric equipment upgrades with energy-intensive operations (e.g., tilling, plowing)

Choose modular platforms (e.g., MINNUO) to reduce upfront costs and maximize equipment reuse

Economic Feasibility Evaluation

ROI Calculation:

Initial Investment = Equipment + Installation + Wiring + Training

Annual Savings = Less fuel/electricity + lower diesel maintenance + reduced labor

Typical ROI: 3–5 years for small farms, faster for large livestock or greenhouse operations

Routine O&M Costs:

PV maintenance ≈ 1% of system value per year

Biogas requires regular seal/temperature checks; assign an inspector

Electric tractors need battery swaps, tire maintenance, etc.

Seek Local Subsidies or Financial Support:

Look for programs like “Solar Ag Demonstration,” “Electric Machinery Subsidies,” “Green Energy Awards”

Most regions offer 30%-50% upfront equipment grants

Siting and System Design Recommendations

| Component | Recommendation |

| Solar PV layout | Prioritize rooftops, barns, carports, fishponds to save land; avoid shaded areas |

| Storage & inverter location | Near main power box, well-ventilated, waterproof and rodent-proof, easy maintenance |

| Biogas system siting | Away from dense zones, downwind of pens; allow space for digester and gas piping |

| Tractor charging zone | Near field entrance and main power room; safe paths, ample sunlight, modular-ready |

Conclusion

As energy price volatility and sustainability demands intensify, energy-independent farming is emerging as a vital pillar of global agricultural transformation. By integrating solar power, biogas, and electric agricultural machinery into a clean, unified system, farms can reduce operational costs, minimize external dependency, boost efficiency, and cut carbon emissions—while qualifying for green subsidies and carbon credit benefits.

This model is particularly well-suited for small family farms, greenhouse operations in hilly regions, and cooperatives upgrading to smart agriculture. It holds strong promise for scalable implementation.

As a pioneer in clean agricultural equipment, MINNUO is building an integrated energy solution centered on electric machinery, modular work platforms, and energy-compatible interfaces. Our goal is to deliver affordable, reliable, and long-lasting smart farming systems. Through phased strategies, scalable design, and remote monitoring support, MINNUO is turning energy independence from concept into reality—helping farms worldwide transition from “saving a barrel of fuel” to “greening the entire field.”