Dairy farming is no longer just about manual labor and traditional practices. The global dairy industry is undergoing a seismic shift driven by technological innovation, sustainability demands, and the urgent need to address labor shortages. For small to medium-sized farms, choosing the right milking machine is no longer optional—it’s a survival strategy. With rising operational costs, stricter hygiene standards, and consumer pressure for ethically produced milk, farmers must navigate a complex landscape of automation, energy efficiency, and animal welfare. This guide dives deep into the top milking machine brands tailored for farms with herds ranging from 10 to 200 cows, offering actionable insights to help you make informed decisions.

Why does your farm need the right milking machine? The answer lies in three critical challenges: profitability, sustainability, and scalability. Smaller farms often lack the financial buffer to absorb inefficiencies, making cost-effective, low-maintenance equipment essential. Simultaneously, consumers and regulators demand transparency in animal welfare and environmental impact, pushing farms toward energy-efficient and eco-friendly solutions. Finally, as herds grow, equipment must adapt without requiring massive reinvestments. This guide addresses these pain points head-on, analyzing brands that excel in affordability, automation, and adaptability.

By 2030, the global milking machine market is projected to exceed $3.5 billion, driven by advancements in robotics, IoT integration, and renewable energy compatibility. Whether you’re a tech-savvy farmer eyeing full automation or a budget-conscious operator prioritizing durability, this article will equip you with the knowledge to future-proof your dairy operations.

Contents

Key Challenges for Small and Medium Farms

Before exploring brands, let’s dissect the hurdles these farms face:

1. Limited Budget: High upfront costs for advanced systems can strain finances, especially for farms with fewer than 50 cows.

2. Labor Shortages: Automation reduces dependency on skilled workers, but training and maintenance remain barriers.

3. Energy Costs: Electricity prices have risen by 18% globally since 2020, making energy-efficient models critical.

4. Animal Health: Mastitis costs the dairy industry $2 billion annually; early detection systems are non-negotiable.

5. Scalability: Equipment must grow with herds—modular designs allow incremental upgrades without full replacements.

Top 7 Milking Machine Brands for 2025

1.SWADESI KRAFTS A2 Cow Milking Machine

Best For: Farms with 8–20 cows | Price Range: $1,200–$2,500

Key Features:

• 200 LPM Vacuum Pump: Milks one cow in 4–5 minutes, ideal for small-scale efficiency.

• 15-Liter Stainless Steel Tank: Powder-coated for corrosion resistance, easy to clean with food-grade standards.

• Foldable Rubber Nipples: Reduces udder injuries by 30% compared to rigid designs.

Why It Stands Out:

SWADESI KRAFTS bridges affordability and functionality. Its A4 and A6 models cater to growing herds (up to 50 cows), ensuring scalability. Farmers in India and Southeast Asia praise its durability in humid climates, with maintenance costs 40% lower than competitors.

User Case: A 15-cow farm in Kerala reduced milking time by 2 hours daily, boosting milk yield by 12% due to reduced cow stress.

2.Cowtools Milking Machine

Best For: Off-grid farms | Price Range: $1,800–$3,000

Key Features:

• Inverter Compatibility: Operates on household inverters during outages—critical in rural India and Africa.

• Automatic Sensing Technology: Stops milking when flow ceases, preventing overmilking and teat damage.

• Low Noise (<60 dB): Minimizes cow stress, aligning with EU animal welfare standards.

Why It Stands Out:

Cowtools excels in regions with unstable power. Its variable pressure regulator allows customization for different breeds, from Holsteins to Jerseys. A Kenyan farm reported a 20% drop in energy bills after switching to Cowtools.

3.Bagayatdar Jambo 0.5 HP Single Bucket Machine

Best For: Micro-farms (1–15 cows) | Price Range: $800–$1,500

Key Features:

• Mastitis Indicator: Alerts farmers via LED lights, reducing treatment delays by 75%.

• 150 LPM Vacuum Pump: Compact yet efficient, fitting barns under 500 sq. ft.

• Copper-Winding Motor: 50% longer lifespan than aluminum counterparts.

Why It Stands Out:

Bagayatdar’s affordability and health monitoring make it a favorite in South Asia. Its 25-liter stainless steel bucket meets FDA hygiene standards, crucial for farms supplying local cooperatives.

4.Lely Astronaut A5 Robotic System

Best For: Tech-driven farms | Price Range: $150,000–$200,000

Key Features:

• Voluntary Milking: Cows self-schedule milking, boosting yield by 15%.

• Real-Time Health Monitoring: Tracks milk conductivity for early mastitis detection.

• Solar Compatibility: Cuts energy costs by 30% with hybrid solar-grid setups.

Why It Stands Out:

Lely’s A5 system reduced labor costs by 60% on a 100-cow Dutch farm. Its “Easy First Milking” feature simplifies training for heifers, reducing adaptation time by 50%.

5.DeLaval VMS V300

Best For: Medium farms (20–100 cows) | Price Range: $50,000–$120,000

Key Features:

• GentlePulse Technology: Mimics calf nursing rhythms, improving cow comfort.

• Batch Milking: Handles 8 cows/hour, doubling throughput of older models.

• Cloud-Based Analytics: Integrates with DeLaval’s Herd Navigator for fertility management.

Why It Stands Out:

In a 2024 trial in China’s Shandong Province, the V300 reduced involuntary culling by 22% through improved udder health monitoring. Its modular design allows adding units as herds expand.

6.GEA Monobox

Best For: Hygiene-focused farms | Price Range: $40,000–$90,000

Key Features:

• Closed Milk Circuit: Prevents bacterial contamination, achieving <10,000 CFU/mL milk quality.

• Quick-Change Liners: Reduces downtime by 25% during maintenance.

• Renewable Energy Ready: Compatible with biogas and solar power.

Why It Stands Out:

GEA’s Monobox is a staple in EU organic farms. A German dairy cooperative reported a 40% drop in somatic cell counts after adoption, qualifying for premium milk contracts.

7.Afimilk MilkyWay

Best For: Data-driven farms | Price Range: $30,000–$80,000

Key Features:

• Milk Composition Analysis: Real-time fat/protein tracking optimizes feed plans.

• Heat Detection Accuracy: 95% success rate vs. 70% for visual methods.

• Remote Herd Management: Access data via mobile app—ideal for multi-site operations.

Why It Stands Out:

Afimilk’s collars and sensors cut open days by 40% on an Israeli farm, boosting annual profits by $18,000.

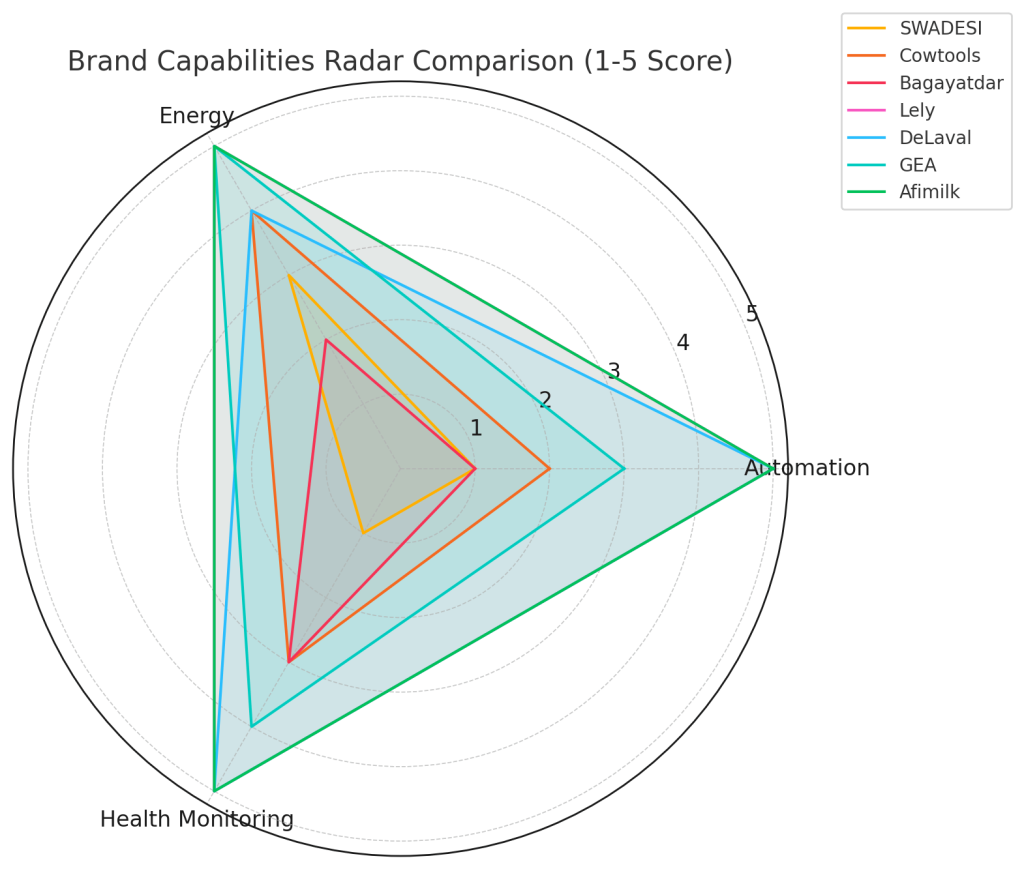

| Brand | Price Range ($) | Ideal Herd Size | Automation Level | Energy Efficient | Health Monitoring |

| SWADESI KRAFTS | 1,200–2,500 | 8–50 | Low | ★★★ | ★ |

| Cowtools | 1,800–3,000 | 10–60 | Low | ★★★★ | ★★★ |

| Bagayatdar | 800–1,500 | 1–15 | Low | ★★ | ★★★ |

| Lely A5 | 150,000–200,000 | 100+ | High | ★★★★★ | ★★★★★ |

| DeLaval V300 | 50,000–120,000 | 20–100 | High | ★★★★ | ★★★★★ |

| GEA Monobox | 40,000–90,000 | 20–100 | Medium | ★★★★★ | ★★★★ |

| Afimilk | 30,000–80,000 | 50–200 | High | ★★★★★ | ★★★★★ |

Emerging Trends Shaping the Market

1. Energy Efficiency: Solar-powered systems like Lely’s A5 and GEA’s Monobox reduce reliance on grids.

2. AI-Driven Health Predictions: Afimilk’s algorithms predict ketosis 48 hours before symptoms.

3. Modularity: DeLaval’s V300 and SWADESI’s A-series allow incremental scaling.

4. Ethical Consumerism: Gentle milking tech (e.g., GentlePulse) aligns with Whole Foods’ animal welfare standards.

How to Choose the Right Machine: A 5-Step Framework

1.Assess Herd Size:

• <15 cows: Bagayatdar Jambo or SWADESI A2.

• 20–100 cows: DeLaval V300 or GEA Monobox.

• 100+ cows: Lely A5 or Afimilk MilkyWay.

2.Budget Allocation:

• Manual systems: $800–$5,000.

• Semi-automatic: $5,000–$30,000.

• Robotic: $50,000–$200,000.

3.Energy Profile:

• Off-grid: Cowtools (inverter-ready).

• Solar-powered: Lely A5.

4.Labor Availability:

• Low-skilled teams: Afimilk’s app-driven systems.

• Tech-savvy staff: Lely or DeLaval robotics.

5.Future-Proofing:

• Opt for modular designs (e.g., SWADESI A-series).

• Prioritize IoT compatibility (Afimilk, DeLaval).

The Future of Milking Technology: 2030 Outlook

1. AI-Enhanced Herd Management: Predictive analytics will flag diseases like lameness 72 hours in advance.

2. Carbon-Neutral Systems: Solar/wind hybrids will dominate, supported by carbon credit programs.

3. Subscription Models: Pay-as-you-go leasing (e.g., Nedap’s HerdMonitor) cuts upfront costs.

4. 5G Integration: Real-time data streaming for remote herd monitoring (tested in UK 5G cow collars trials).

Conclusion

For small and medium dairy farms, the milking machine is no longer just a tool—it’s the backbone of profitability, herd health, and long-term growth. Whether you’re managing 15 cows or expanding to 100+, the right equipment helps you reduce labor dependency, optimize yield, and meet the rising demands of ethical and sustainable milk production.

From cost-effective starters like SWADESI KRAFTS and Bagayatdar, to advanced automation from Lely, DeLaval, and Afimilk, today’s market offers options for every budget, energy setup, and herd profile. As technology evolves, it’s crucial to choose systems that grow with your farm—think modularity, remote monitoring, and animal-friendly design.

At MINNUO Agricultural Machinery, we help farms around the world simplify this decision. Our team works closely with you to match the right milking solution—based on your herd size, power supply, space layout, and future expansion plans.