Modern agricultural equipment in agricultural production is increasingly important, with the acceleration of the process of AI agricultural machinery modernization, agricultural equipment not only need to have higher productivity and greater durability, but also in the intelligent management and automation of the operation of a breakthrough. The high reliability and efficiency of agricultural equipment directly affects the stability of agricultural production and yield. How to ensure the efficient operation of equipment while reducing downtime and unnecessary maintenance has become an important issue in agricultural production.

In response to the high maintenance costs and equipment failure rates faced by agricultural equipment, predictive maintenance and intelligent operation and maintenance technologies have emerged. Traditional agricultural maintenance often relies on regular maintenance and manual inspection, which is not only costly, but also easy to miss potential problems. Through the introduction of intelligent equipment monitoring systems and data analysis technology, agricultural enterprises can monitor the operating status of equipment in real time and warn of equipment failures in advance, greatly reducing downtime and maintenance costs.

With the development of technology, the combination of AI and big data is bringing changes to agricultural equipment management. The intelligence of agricultural equipment can not only improve production efficiency, but also achieve more accurate equipment maintenance and resource scheduling, thus promoting the optimization of agricultural production mode. As more and more agricultural enterprises begin to adopt intelligent operation and maintenance systems, agricultural production will usher in a new era of more efficient, green and intelligent. In this article, we will discuss in depth how to choose a suitable AI O&M solution to realize the efficient management and sustainable development of agricultural equipment.

Contents

- 1 Ⅰ. Concept and Development of Predictive Maintenance

- 2 II. Impact of predictive maintenance on the agricultural machinery industry

- 3 III. The combination of cost control and AI operation and maintenance

- 4 IV. Challenges faced and future outlook

- 5 V. How to Choose a Suitable AI O&M Solution

- 6 Conclusion

Ⅰ. Concept and Development of Predictive Maintenance

Overview of Predictive Maintenance

Predictive Maintenance (PdM) is a technical means to determine the timing of equipment maintenance by predicting equipment failures, so as to achieve the optimal operating condition of the equipment and minimize maintenance costs. Different from the traditional periodic maintenance and repair maintenance, Predictive Maintenance relies on real-time monitoring and analysis of equipment operation data, and is able to make early warnings before equipment failures occur, thus avoiding sudden shutdowns and production interruptions.

Basic Principles and Technologies of Predictive Maintenance

The core technologies of predictive maintenance mainly include sensor technology, data acquisition technology, data analysis and processing technology, and artificial intelligence technologies such as machine learning. By installing sensors on the equipment, a number of key operating parameters, such as temperature, vibration, pressure, and rotational speed, are collected in real time and transmitted to the analysis platform.

The role of AI in predictive maintenance: the introduction of artificial intelligence technology provides predictive maintenance with powerful data processing and prediction capabilities. Through deep learning and pattern recognition technology, AI can identify the operating patterns and potential failure modes of equipment from massive historical data, thereby improving the accuracy and timeliness of prediction.

Application of Predictive Maintenance in Agricultural Machinery

In agricultural machinery, the efficient operation of equipment is directly related to production efficiency and cost control. The application of predictive maintenance in agricultural machinery is mainly reflected in the real-time monitoring of the working status of the equipment and data analysis, to find the potential risk of equipment failure in advance, to avoid the loss caused by the failure of downtime. For example, by monitoring the vibration, temperature, pressure and other data of the machinery, the wear and tear of mechanical components and possible failures can be predicted in advance, so that maintenance or replacement can be carried out before the problem affects production.

How to analyze and predict failures through real-time data: with modern Internet of Things (IoT) technology, agricultural machinery can be monitored online around the clock. This data can be transmitted to a cloud-based platform via a wireless network and analyzed in conjunction with machine learning algorithms to provide decision support for equipment maintenance.

Enhance the efficiency and reliability of agricultural production: the traditional way of maintaining agricultural machinery often relies on regular overhaul, but due to the equipment being in a high-load working condition for a long time, there may be certain risks. Predictive maintenance can determine the maintenance time according to the actual operating conditions of the equipment, thus extending the service life of the equipment and reducing downtime, thus improving production efficiency.

Development Trend

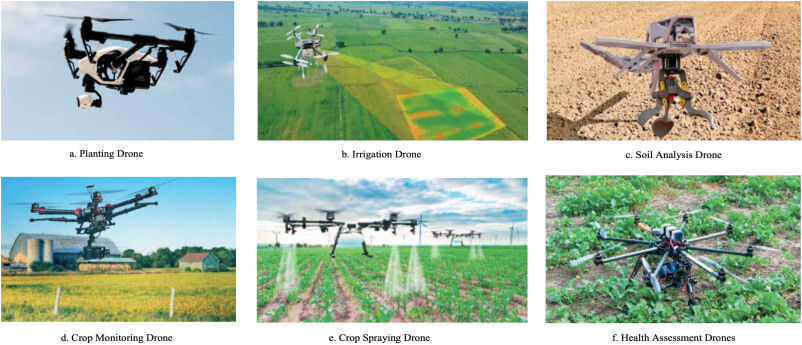

Intelligent Upgrading of Agricultural Equipment

With the continuous improvement of agricultural mechanization, more and more agricultural equipment will adopt intelligent management, and predictive maintenance will become an important part of it. The wide application of intelligent sensors will enable agricultural machinery to have real-time self-diagnosis and self-repair capabilities, thus improving the operational reliability and productivity of the equipment.

Application of 5G and IoT Technology

The widespread application of 5G technology and IoT will further promote the popularization of predictive maintenance in agricultural machinery. The high-bandwidth, low-latency 5G network can support the high-speed transmission of equipment data, and the real-time transmission of data can help farm operators keep track of the operational status of equipment. Combined with AI technology, it can take countermeasures in advance before failures occur, greatly reducing maintenance costs.

II. Impact of predictive maintenance on the agricultural machinery industry

Reducing operational costs

Accurate predictive maintenance can effectively avoid unnecessary repairs and over-maintenance. Through real-time monitoring and data analysis, farm equipment can be warned of failures before they occur, ensuring that repairs are only carried out when they are really needed. As a result, farmers and agricultural producers can reduce unnecessary downtime and repair costs, which can significantly lower operating costs.

Improving equipment reliability and extending life

Regular predictive maintenance not only reduces the incidence of equipment breakdowns, it also extends the life of farm equipment. By fixing potential problems in a timely manner, equipment is able to maintain a high level of operational efficiency and reduce repair costs due to aging equipment. Ongoing monitoring and maintenance safeguards ensure that equipment is always in optimal working condition, providing a more reliable guarantee for agricultural production.

Improve Farmer Productivity

Predictive maintenance helps farmers improve agricultural productivity through accurate equipment monitoring and timely maintenance. Fewer equipment breakdowns mean that farm work can be carried out more efficiently, with fewer interruptions to production. Instead of worrying about sudden equipment downtime, farmers are able to focus more on crop production and management, improving overall farm efficiency.

Boosting Agribusiness Productivity

Adoption of predictive maintenance by agribusinesses not only reduces equipment failure rates, but also optimizes the use of resources. By improving equipment availability and efficiency, businesses can maximize productivity and output. Intelligent management of agricultural equipment can lead to higher resource utilization efficiency, while reducing disruptions in the production process and improving the overall competitiveness of the enterprise.

Optimizing Resource Management

With smarter equipment, agribusinesses can better manage human, time and material resources. Predictive maintenance systems can help agribusinesses efficiently dispatch equipment and personnel through accurate data analysis, avoiding overconsumption and ineffective inputs. Reasonable resource allocation and optimized management can not only enhance the economic benefits of enterprises, but also promote the sustainable development of the agricultural industry.

III. The combination of cost control and AI operation and maintenance

The combination of AI and big data: accurate cost control

With the development of big data technology, the application of AI in agricultural equipment management is no longer a dream of the future, but a realistic solution. Through big data analysis, AI is able to accurately predict equipment failure points and adjust maintenance strategies based on real-time data, avoiding over-maintenance and resource wastage.The AI system not only issues early warnings before equipment problems occur, but also automatically adjusts the maintenance frequency and operations based on the actual operating conditions of the equipment, thus drastically reducing maintenance costs.

How to realize dynamic budget management and flexible scheduling

The application of AI in agricultural equipment management is not only limited to equipment forecasting, but also extends to capital and resource management. Through the analysis of historical data, the system can accurately predict the maintenance needs of different equipment and intelligently adjust the budget allocation by combining the seasonal changes in agricultural production.AI can dynamically adjust the deployment of resources and funds based on the frequency of use, the probability of failures, and the maintenance history of the equipment, so as to maximize the efficiency of the use of funds, and to avoid over-investment and waste of resources.

This flexible budget management model can help agricultural enterprises quickly adjust their maintenance plans in the face of uncertain market and climate conditions, ensuring a more flexible and effective flow of funds.

Case Study: Successful Application Examples of Agricultural AI Operation and Maintenance

With the gradual maturation of AI technology, more and more agribusinesses have begun to explore how to apply AI technology to the management and operation and maintenance of agricultural machinery. Here are a few successful cases:

Successful Cases: How to Optimize Equipment Operation and Reduce Costs through AI

In an agricultural enterprise, the introduction of AI operation and maintenance management system has successfully realized the intelligent prediction and scheduling of agricultural machinery. The AI system combines the weather changes, the equipment operation status and the production demand to intelligently adjust the maintenance plan and the arrangement of the equipment use, which not only significantly reduces the equipment’s downtime, but also optimizes the equipment maintenance cycle and reduces the number of equipment maintenance cycles. The system not only significantly reduces equipment downtime, but also optimizes the maintenance cycle of the equipment, reduces the waste of manpower and material resources, and lowers the overall operating costs by 15%.

Agricultural Machinery Manufacturer Case: A Win-Win for Productivity Improvement and Cost Control

An agricultural machinery manufacturer optimized the equipment management of its production line through an AI operation and maintenance system. AI analyzes the real-time production data and predicts potential problems with the equipment, and carries out targeted repairs and replacements in advance, avoiding sudden equipment failures and production line stoppages. The implementation of the system has increased the overall efficiency of the equipment by 20% and reduced maintenance costs while avoiding unnecessary production interruptions and overall cost reductions.

IV. Challenges faced and future outlook

Challenges

Acceptance of AI technology in the agricultural industry and barriers to technology diffusion

Despite the great potential of AI technology in the agricultural machinery sector, the acceptance of AI technology in the agricultural industry is still facing certain challenges. Many farms and agricultural producers are hesitant to embrace the technology transition process, especially for small and medium-sized agribusinesses, where the high cost and technical complexity of AI technology may be overwhelming. In addition, the unique nature of agriculture requires AI systems to be able to adapt to changing climates, soils, and crop types, and most current AI solutions still struggle to meet such a wide range of needs.

Quality Issues in Data Integration and Processing

The core of AI technology lies in data, especially in agriculture, where data from farm equipment, soil conditions, weather changes, and many other aspects need to be collected and processed in real time. However, agricultural equipment has different ways of data collection, and the quality and consistency of the data varies greatly. How to effectively integrate data from different sources and formats and ensure data quality is a key challenge in realizing accurate AI O&M management.

Future Outlook

Technological Breakthroughs and Innovations in Agricultural AI O&M

In the future, with the continuous development of AI technology, more technological breakthroughs will be ushered in the agricultural field.The future of AI O&M is not only the management of equipment, but also the core driving force of intelligent agricultural production. Through continuous technological innovation, AI will be able to realize comprehensive intelligence from crop growth to equipment operation and maintenance. For example, AI will be able to analyze multi-dimensional data such as climate change and crop health, predict possible problems in agricultural production in advance, and propose intelligent solutions to achieve fully optimized agricultural management.

Comprehensive Upgrade from Equipment Failure Prediction to Intelligent Scheduling and Automatic Repair

AI technology will be further developed to break the traditional limitations of equipment failure prediction and repair, and move towards a new era of intelligent scheduling and automatic repair of equipment. With more advanced IoT technology and deep learning models, agricultural machinery will not only be able to predict failures, but also automatically dispatch according to the needs of agricultural production, thus reducing human intervention and realizing automated management and self-repair of equipment. This will greatly improve the efficiency of agricultural production and reduce equipment failure rates and downtime.

V. How to Choose a Suitable AI O&M Solution

Evaluating the Core Functions of the AI O&M Platform

Stability and Compatibility of the Data Acquisition and Monitoring System

When choosing an AI O&M solution, you first need to evaluate the stability of its data acquisition and monitoring system. Agricultural machinery and equipment operate in different environments, and data collection equipment needs to be able to stably collect various types of information, such as equipment operating parameters, weather changes, soil conditions, etc. Therefore, one of the core functions of the AI O&M platform is to have a highly stable real-time data monitoring capability that can provide accurate data feedback over a long period of time.

Accuracy of Algorithms and Predictive Capacity

An important evaluation criterion for AI O&M solutions is the accuracy of their predictive algorithms. The accuracy of the algorithm is directly related to the accuracy of equipment failure prediction and the improvement of operational efficiency. High-precision algorithms can accurately predict the possible failure points of equipment through the learning of equipment history data, and formulate effective maintenance plans in advance, thus avoiding sudden equipment failures and ensuring the stability of production.

Partners and Technical Support

Choose an AI operation and maintenance service provider with strong technical support and the ability to upgrade for a long time

When choosing a partner, the first thing to consider is its technical support capability. In the process of agricultural production, sudden equipment failures and complex working environments put forward higher requirements for the timely response of operation and maintenance services. An excellent AI O&M solution provider should have a strong technical support team that can quickly respond and solve practical problems. In addition, long-term system upgrade and optimization are also important considerations.

Technical Ideas and Innovative Capabilities Provided by Partners

When choosing a partner, you also need to pay attention to its technical ideas and innovative capabilities. A good AI O&M solution provider should have the spirit of innovation, be able to propose practical technical solutions based on industry needs, and continuously promote the progress of technology. When choosing a partner, you should not only assess the maturity of its existing technology, but also pay attention to its future technology development direction and investment. A long-term and stable partnership can provide agribusinesses with sustained technical assurance and competitiveness support.

Cost-benefit analysis

Comprehensively consider the long-term benefits of equipment procurement and AI O&M system investment

When choosing an AI O&M solution, it is important to conduct a comprehensive cost-benefit analysis. The first step is to evaluate the initial procurement cost of the equipment and the investment cost of the AI operation and maintenance system. the introduction of AI technology is often accompanied by a certain amount of initial investment, but its long-term benefits far exceed the cost of the initial investment. For example, AI systems can help organizations save a lot of money on maintenance and equipment replacement costs by improving equipment operating efficiency, reducing failure rates, and extending equipment life.

Analyzing ROI (Return on Investment)

Evaluating the ROI (Return on Investment) of an AI O&M system is an important step in choosing the right solution. ROI calculations should be based on a combination of factors such as equipment energy savings, reduced downtime, increased productivity, etc. AI O&M systems help maximize equipment efficiency and reduce unnecessary production downtime through improvements in real-time equipment monitoring, fault prediction, and maintenance optimization.

Conclusion

Predictive maintenance and cost control have become the latest trend in the field of agricultural machinery O&M. Through the combination of AI and big data technology, intelligent management of agricultural equipment is increasingly becoming the mainstream of the industry, which can effectively reduce O&M costs, improve the efficiency of equipment use, and extend the service life of equipment. With the continuous development of technology, AI will play a more indispensable role in agricultural production in the future. For farmers and enterprises, AI operation and maintenance can not only improve production efficiency, but also guarantee the stability of the equipment at the same time, better control costs, and promote the sustainable development of enterprises.

MINNUO is committed to providing efficient and intelligent equipment management solutions for the agricultural industry, and its advanced AI O&M services are helping more and more agribusinesses to optimize equipment management and reduce maintenance costs. By introducing MINNUO’s intelligent O&M system, agricultural equipment will be more accurately maintained and scheduled, resulting in more efficient and stable operations. In the future, MINNUO will continue to move forward on the road of technological innovation, provide more accurate and efficient solutions for agricultural enterprises, and help the global agricultural industry move towards a new stage of intelligent and sustainable development.