- Home

- Products

- Harvester

- Self-propelled Rice Combine Harvester

- 200HP Self-Propelled Grain Combine Harvester 4LZ-10

200HP Self-Propelled Grain Combine Harvester 4LZ-10

The 4LZ-10 self-propelled full-feeding combined grain harvesting machine adopts cut flow + transverse axial flow roller threshing and separation technology, with strong threshing ability and complete material separation; the overall machine structure is reasonably designed and easy to maintain; the new peripheral design, it has beautiful lines, practicality and beauty; it mainly harvests wheat, and the replacement. Darts can also harvest rice, soybeans, rapeseed, miscellaneous grains, and cor grains, it is suitable for cross-regional operations in most parts of my country.

Previous slide

Next slide

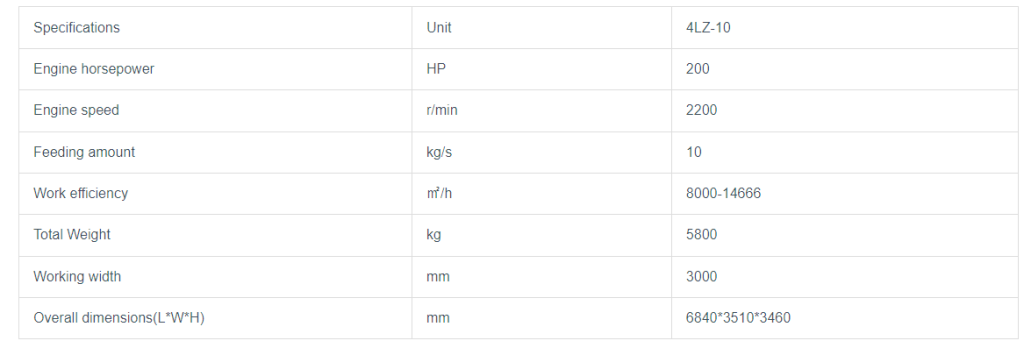

parameters

| Specifications | Unit | 4LZ-10 |

| Engine horsepower | HP | 200 |

| Engine speed | r/min | 2200 |

| Feeding amount | kg/s | 10 |

| Work efficiency | ㎡/h | 8000-14666 |

| Total Weight | kg | 5800 |

| Working width | mm | 3000 |

| Overall dimensions(L*W*H) | mm | 6840*3510*3460 |

Features

- The cutting table can be equipped with a quick-hook cutting table, which is more convenient and can be completed independently.

- An anti-grass entanglement device is added to the right side of the reel, which greatly reduces the product maintenance time duringthe operation and improves the operation efficiency;

- The axial flow roller width plate is re-opened, and the separation plate and nailteeth are heat treated to make the quality more reliable; the axial flow roller shaft tube is thickened to $68, the material is cold-drawn steel pipe, hot-fitting process is used, and the shaft head diameter is thickened to p50 , the material was changed to 42crMo, which greatly improved the working intensity.

- The engine power was increased to 200 horsepower, and a multi-function switch was added, The horsepower can be changed between125 and 200 horsepower to meet more needs of users; the power output pulley was changed from $248 to p272, the walking speed isincreased by 10%,and the operating efficiency is higher.

- The power putout joint belt, walking belt, and threshing drum belt are all made of red label belts, which increases the service life, reducesthe replacement cycle, and improves the operating efficiency.

- Optional electromagnetic The valve is operated by one rod, and the original air conditioner is optional.

- Improve the strength of thehydraulic main clutch tensioning arm, the joint fork, and the adjusting screw are increased from 12mm to 16mm to increase the strength prevent deformation,and greatly extend the product life.

- Diesel The box is enlarged, and the battery life is increased by 20%.

- The chassis is made of 16mn high-strength material, the reinforcing plate is lengthened, the welding process is changed, the strength ofthe frame is improved, the service life of the whole machine is greatly increased, and the value retention rate is higher.

- The intermediate shaft is made of 42crMo solid The shaft is thickened, the bearing is upgraded from 207 to 210, the strength is increased by25%, and the quality and reliability of the whole machine are improved.