In agricultural operations, tractors are invaluable tools that drive productivity and efficiency. Whether used for tilling, plowing, or hauling, tractors are integral to performing a variety of farming tasks. However, as with any machinery, the efficiency and longevity of a tractor depend heavily on the performance of its internal components, especially the clutch and transmission. These two components are not only essential for the proper functioning of the tractor but also directly impact its overall operational performance, ease of use, and long-term maintenance needs.

Many farmers, especially those new to tractor operation, often find it challenging to understand the specific roles of the clutch and transmission. While these components are both crucial for the tractor’s movement, their functions differ significantly. The clutch facilitates the smooth engagement and disengagement of the engine, while the transmission controls the selection of gears to adjust the tractor’s speed and torque. A lack of understanding of how each system works can lead to inefficient use of the tractor, improper maintenance, and even premature equipment failure.

In the following sections, we will dive deeper into the specific functions of the tractor clutch and transmission, exploring how each system contributes to the tractor’s overall operation. Additionally, we will discuss how understanding these systems can help farmers make better decisions regarding tractor selection, operation, and ongoing maintenance. Keep reading to learn more about these essential tractor components and how their proper functioning directly impacts your farm’s success.

Contents

1. The Tractor Clutch: Purpose and Function

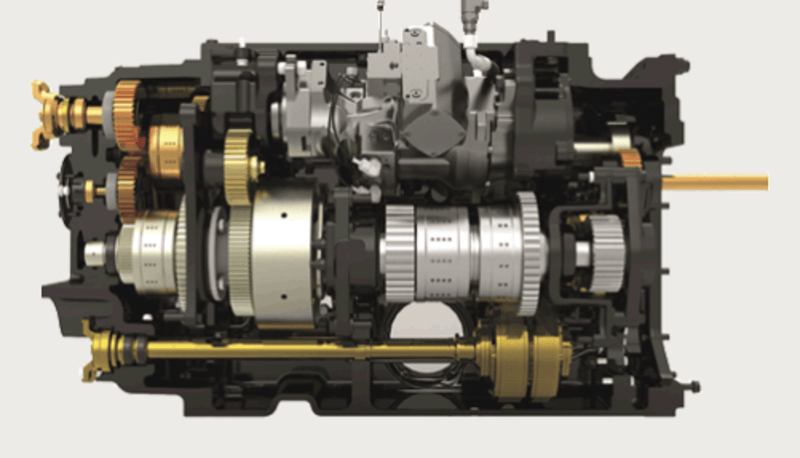

A tractor clutch plays a pivotal role in ensuring that a tractor operates smoothly by controlling the connection between the engine and the drivetrain. It allows the operator to start, stop, and shift gears without causing engine stalls or damaging the transmission system.

What Is a Tractor Clutch?

The clutch is a mechanical device that facilitates the engagement and disengagement of the tractor’s engine from its drivetrain. This action ensures that the tractor’s power is smoothly transmitted from the engine to the wheels, allowing the operator to control the power transfer effectively. When the clutch is pressed, the engine and wheels are decoupled, enabling the operator to shift gears or stop the tractor without stalling the engine. When the clutch is released, the engine and wheels are re-engaged, allowing for movement.

How It Works:

The clutch works through a series of friction plates that engage and disengage when the operator presses or releases the clutch pedal. As the pedal is pressed, these plates are separated, disconnecting the engine from the wheels. Once the pedal is released, the plates are pressed together, transferring engine power to the wheels, enabling movement.

Clutch Mechanism and Functionality:

Engagement: Smooth engagement of the clutch is necessary to prevent jerking, which can lead to wear and tear of the engine or drivetrain.

Disengagement: A smooth disengagement ensures that gears can be shifted without grinding or causing stress on the internal components.

Types of Tractor Clutches

Single Clutch vs. Dual Clutch:

Single Clutch Systems:

Common in: Older, simpler tractor models.

Usage: Best suited for basic farming tasks like light plowing, tilling, or hauling.

Advantages: Cost-effective and easier to maintain for general tasks.

Disadvantages: Less efficient in high-load operations or heavy-duty tasks due to less control during gear shifts.

Dual Clutch Systems:

Common in: More advanced, modern tractors.

Usage: Preferred for heavy-duty tasks such as continuous hauling, heavy plowing, or high-speed operations.

Advantages: Offers smoother gear shifting and enhanced performance during heavy tasks.

Disadvantages: More complex and slightly more expensive than single-clutch systems.

Common Problems and Signs of a Worn Clutch

Slipping Clutch:

If the clutch is slipping, the engine’s power may not be fully transmitted to the wheels, resulting in reduced power and poor performance, especially when the tractor is under load.

Grinding or Sticking Gears:

If you notice that gears grind or don’t shift smoothly, it could indicate that the clutch is not disengaging fully. This can cause further damage to the transmission if not addressed.

Unusual Noises or Vibrations:

Excessive noise or vibrations during operation may indicate a problem with the clutch plates or the clutch pedal linkage.

Difficulty in Shifting Gears:

When a tractor becomes difficult to shift into gear, it could be a sign that the clutch is either not disengaging properly or is nearing the end of its useful life.

2. The Tractor Transmission: Purpose and Function

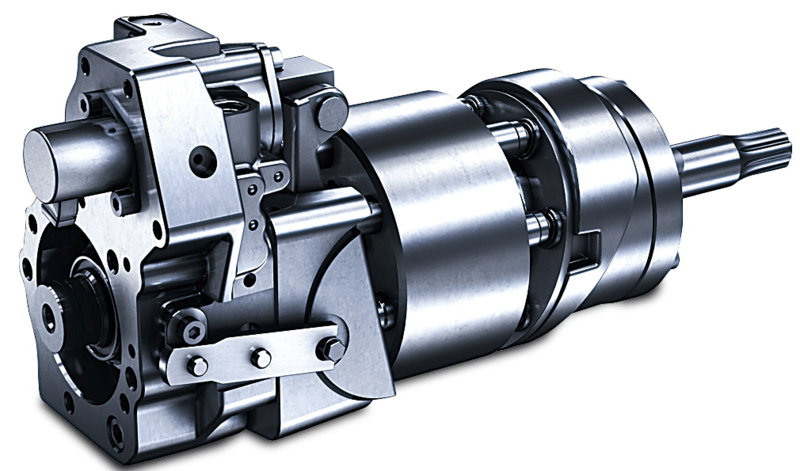

A tractor transmission is a critical component that controls the speed, torque, and power delivery from the engine to the wheels. It is designed to allow the tractor to operate efficiently across a variety of tasks, such as plowing, hauling, and tilling. By selecting the appropriate transmission type, farmers can ensure optimal power delivery for each farming task.

What Is a Tractor Transmission?

The transmission in a tractor is a system of gears and shafts that regulates the speed and torque output of the engine. It determines how much engine power is delivered to the wheels based on the needs of the task. The transmission allows the tractor to operate at various speeds and power levels, providing the necessary force for different types of work, such as high torque for heavy plowing or lower speeds for precise tilling.

How It Works:

The tractor’s transmission works by using a set of gears that can be manually or automatically shifted based on the tractor’s needs. These gear changes allow for different power outputs, enabling the tractor to perform tasks that require varying levels of strength, speed, and control. For example, when preparing soil or hauling heavy loads, higher torque is needed, while lower speeds may be used for tasks requiring precision, like mowing or planting.

Gear Selection: The transmission allows for manual or automatic shifting between gears, ensuring the tractor operates efficiently depending on the load and field conditions.

Power Delivery: Transmission regulates how the engine power is directed to the wheels to ensure proper traction and force to complete specific tasks.

Types of Tractor Transmissions

Manual Transmission:

Overview:

Manual transmissions are commonly found in older or budget-friendly tractor models. These tractors require more operator involvement to select gears manually, giving the operator more control over the gear shifts.

Advantages:

Control: Provides complete control over gear shifts, which can be beneficial for specific, skill-based tasks where manual precision is needed.

Simplicity: Fewer mechanical parts may mean fewer repairs and less initial cost compared to more advanced systems.

Disadvantages:

Operator Skill: Requires the operator to be well-versed in gear changes and tractor handling.

Effort: More effort is required from the operator to shift gears, especially during long hours of operation.

Automatic Transmission:

Overview:

Automatic transmissions are commonly used in modern tractors. These systems shift gears automatically based on engine speed and load, reducing the need for manual intervention.

Advantages:

Ease of Use: Simplifies the driving experience, allowing the operator to focus more on the task at hand than shifting gears.

Efficiency: Automatic transmission systems ensure that the tractor runs at optimal speeds for fuel efficiency, reducing unnecessary fuel consumption.

Disadvantages:

Complexity: More components and higher initial costs compared to manual systems.

Maintenance: While maintenance is typically low, repairs can be more expensive due to the complexity of the system.

Power Shift Transmission:

Overview:

Power shift transmission allows for gear changes without needing to stop the tractor. This is a feature commonly found in high-performance and commercial-grade tractors designed for heavy-duty tasks.

Advantages:

Continuous Operation: Gear changes can be made without halting operations, which is ideal for tasks that require consistent speed, such as hauling, plowing, or mowing large fields.

Heavy-Duty Tasks: Suitable for tractors handling large implements or operating in challenging terrains where consistent power and speed are necessary.

Disadvantages:

Cost: Power shift systems are typically more expensive, both in terms of purchase price and repairs.

Complexity: These systems can be more complex and may require specialized maintenance.

3.Key Differences Between Tractor Clutch and Transmission

When choosing a tractor, understanding the differences between the clutch and transmission is crucial for farmers to operate efficiently and effectively. Both are essential components in controlling the power delivery from the engine to the wheels, but they serve distinct roles. Here’s a deeper look at their functionality, interdependence, and role in tractor operation:

Functionality:

The Tractor Clutch:

Primary Function: The clutch connects and disconnects the engine from the drivetrain, allowing the tractor to start, stop, or shift gears smoothly.

How It Works: The clutch is engaged when the operator presses the pedal, temporarily disengaging the engine’s power from the wheels. This action allows for gear shifts or stopping the tractor without stalling the engine.

Key Point: The clutch controls the engagement and disengagement of power, ensuring that the tractor operates smoothly at various stages of use. Without a properly functioning clutch, it would be impossible to change gears or stop the engine without stalling.

The Tractor Transmission:

Primary Function: The transmission determines how much power is delivered to the wheels and controls the speed and torque of the tractor.

How It Works: The transmission allows the operator to shift gears based on the needs of the operation (such as plowing, hauling, or tilling). It adjusts the tractor’s power to suit specific tasks by selecting the appropriate gear ratio.

Key Point: Transmission systems, whether manual, automatic, or power shift, provide the tractor with the appropriate level of speed and power for various farming tasks, enabling the tractor to adapt to different operational conditions.

Interdependence:

Clutch and Transmission Interaction: The clutch and transmission work together to ensure smooth tractor operation. The clutch enables the tractor to shift gears without stalling, while the transmission adjusts the speed and power once the gear is engaged. Without the clutch, it would be impossible to change gears or stop the engine smoothly, while without the transmission, the tractor would not be able to adjust its speed and power for different tasks.

Example: When performing tasks like plowing, the clutch disengages the engine from the transmission, allowing the operator to shift to a lower gear that provides the necessary torque. As the gear is engaged, the transmission takes over and delivers the required power to the wheels, while the clutch ensures the gear change occurs without stalling the engine.

Role in Tractor Operation:

Clutch:

Control of Power Flow: The clutch plays a key role in managing how the engine’s power is transferred to the wheels. It allows the operator to start or stop the tractor without stalling the engine, which is critical during operations like starting or stopping on inclines or uneven terrain.

Torque Distribution: The clutch also helps manage the distribution of torque, preventing engine stalls during gear shifts or sudden power demands.

Transmission:

Adjusting Speed and Power: The transmission ensures the tractor is running at the optimal speed and power level for different tasks. Whether performing high-torque tasks like heavy plowing or light-speed tasks like mowing, the transmission allows the operator to select the appropriate gear.

Efficiency in Heavy Tasks: Transmission plays a critical role in maintaining high performance and efficiency during tasks like plowing or hauling, ensuring the tractor can handle larger implements with greater ease and stability.

4. How Tractor Clutch and Transmission Impact Tractor Performance

Understanding how the clutch and transmission systems affect tractor performance is essential for making the right decisions when selecting and maintaining a tractor. These two components not only play a pivotal role in ensuring smooth operations but also directly impact the efficiency, cost-effectiveness, and longevity of the tractor. Here’s a deeper look into how each system influences tractor performance:

Performance Optimization

Efficient Fuel Consumption:

Choosing a tractor with the appropriate clutch and transmission system helps optimize fuel usage during various agricultural operations. A well-maintained system ensures that the tractor can shift gears smoothly, avoiding unnecessary fuel consumption during frequent speed changes.

Example: A tractor with an advanced dual-clutch system can change gears without interrupting power flow, allowing for smoother transitions and more fuel-efficient operation during heavy-duty tasks like plowing.

Reduced Operational Costs:

When the clutch and transmission are functioning optimally, the tractor runs more efficiently, leading to reduced wear and tear on the engine and drivetrain. This, in turn, lowers long-term operational costs related to repairs and maintenance.

Cost-saving: Tractors that feature more efficient transmissions, such as power-shift or automatic systems, reduce the likelihood of engine strain, as they offer smoother shifts and better power distribution, especially in demanding tasks.

Extended Tractor Lifespan:

Properly functioning clutch and transmission systems can significantly extend the tractor’s lifespan by minimizing excessive strain on key engine components. Regular maintenance of these systems ensures they operate smoothly, preventing damage to the engine and other drivetrain parts.

Long-term benefit: Farmers can avoid costly repairs and maximize the tractor’s utility by choosing a model with durable components and making sure to maintain the clutch and transmission regularly.

Impact on Tractor Handling

Clutch and Tractor Handling:

Maneuverability: A faulty clutch can lead to poor handling, making it harder to operate the tractor in tight spaces or uneven terrain. Sluggish or erratic engagement can cause jerks during gear shifts, making tasks like turning or backing up difficult.

Issues with Heavy Loads: In scenarios where heavy-duty operations like hauling or plowing are required, a malfunctioning clutch can hinder the tractor’s ability to perform at optimal levels. This can result in unwanted jerking motions, which are not only inefficient but can also damage attachments or the tractor itself.

Example: In a muddy field, if the clutch doesn’t engage properly, the tractor may stall, making it difficult to move, resulting in inefficiencies and potential downtime.

Transmission and Tractor Performance:

A malfunctioning transmission can cause several performance issues, including uneven power distribution, delayed gear changes, and speed control problems. These issues often surface during high-load operations such as tilling or hauling, where consistent power and smooth gear transitions are crucial.

Potential Breakdowns: When the transmission is not functioning properly, it can lead to power loss, especially when tackling tough terrains or large fields. This can cause the tractor to stall, or worse, experience a breakdown under heavy usage.

Example: On a large farm where heavy tilling is needed, if the transmission is not engaging smoothly, the tractor may struggle to maintain speed or torque, causing delays and higher fuel consumption, which negatively affects overall productivity.

5. Maintenance and Care for Tractor Clutch and Transmission

Clutch Maintenance Tips:

Maintaining the tractor’s clutch system is essential for ensuring smooth operation and preventing costly repairs. Regular inspection should be performed to check for signs of wear and tear. A well-maintained clutch ensures that the tractor shifts gears smoothly without stalling or jerking, which is crucial for optimal performance in the field.

To keep the clutch in good condition, look out for the following signs of wear:

Difficulty Shifting Gears: If you notice resistance or grinding when shifting, the clutch may be wearing out and not fully disengaging, leading to unnecessary strain on the transmission.

Strange Noises: Squealing or rattling noises from the clutch area can indicate internal damage or that the clutch components need lubrication or adjustment.

Spongy or Stiff Pedal Feel: A pedal that feels too soft or too hard could indicate problems with the hydraulic system, requiring immediate attention to avoid clutch failure.

Regularly adjusting the clutch, ensuring that it’s properly lubricated, and replacing worn components can help avoid major breakdowns. By addressing small issues early, you can extend the life of your clutch system and avoid costly repairs.

Transmission Maintenance Tips:

The transmission plays a critical role in controlling the tractor’s speed and torque. Regular maintenance of the transmission system is essential to keep it functioning efficiently, reducing the likelihood of performance issues that could impact your ability to complete farm tasks effectively.

Check Fluid Levels Regularly: Transmission fluid is essential for smooth operation and cooling of the system. Make sure to check the fluid level frequently, especially before heavy use, and top it up if necessary. Using the correct type of fluid, as specified by the tractor manufacturer, is essential for optimal performance.

Changing Transmission Fluid: Over time, transmission fluid can break down, reducing its effectiveness. It’s important to replace the fluid according to the manufacturer’s maintenance schedule. Regular fluid changes prevent sludge buildup, which could cause internal damage and inefficiency.

Conclusion

Understanding the distinct roles of the tractor clutch and transmission is essential for choosing the right tractor and maintaining it effectively.

Proper maintenance and understanding how both systems work in tandem will ensure better performance and longevity for the tractor.When selecting a tractor, consider the tasks you’ll be performing, as well as the importance of having reliable and efficient clutch and transmission systems.

MINNUO tractors provide superior clutch and transmission performance, ensuring smooth and efficient operations, minimizing wear and tear, and offering long-term value.