In today’s diverse agricultural operations, one size no longer fits all. From broad-acre grain farms to dense orchards and hilly vineyards, transmission choice has become a critical factor in how efficiently and safely a tractor can perform. Different working conditions require different control responses—and that’s where transmission type steps in as a strategic decision, not just a mechanical detail.

The type of transmission—whether gear-driven or hydrostatic—not only affects how smoothly the tractor shifts but also plays a key role in operator fatigue, task flexibility, and long-term maintenance costs. Gear systems offer raw torque and mechanical simplicity, while hydrostatic systems (HST) provide seamless speed adjustment and ease of use, especially in stop-start environments. But which is better? It depends.

This article helps you decode the technical and practical differences between gear and hydrostatic transmissions. More importantly, it guides you to the best match based on your workload, terrain, and driver experience. Keep reading to discover which transmission system truly fits your farm—not just your budget.

Contents

1.Understanding the Mechanics

The transmission system determines the power transmission efficiency, ease of handling and fuel utilization of a tractor under different working conditions. Understanding the essential differences between the two core technology paths of Gear Transmission and Hydraulic Continuously Variable Transmission (HST) will help users to make a scientific configuration according to the farm size, terrain and work intensity.

1.1 Gear Transmission (Manual / Power Shuttle / Syncro)

Working Principle Explanation:

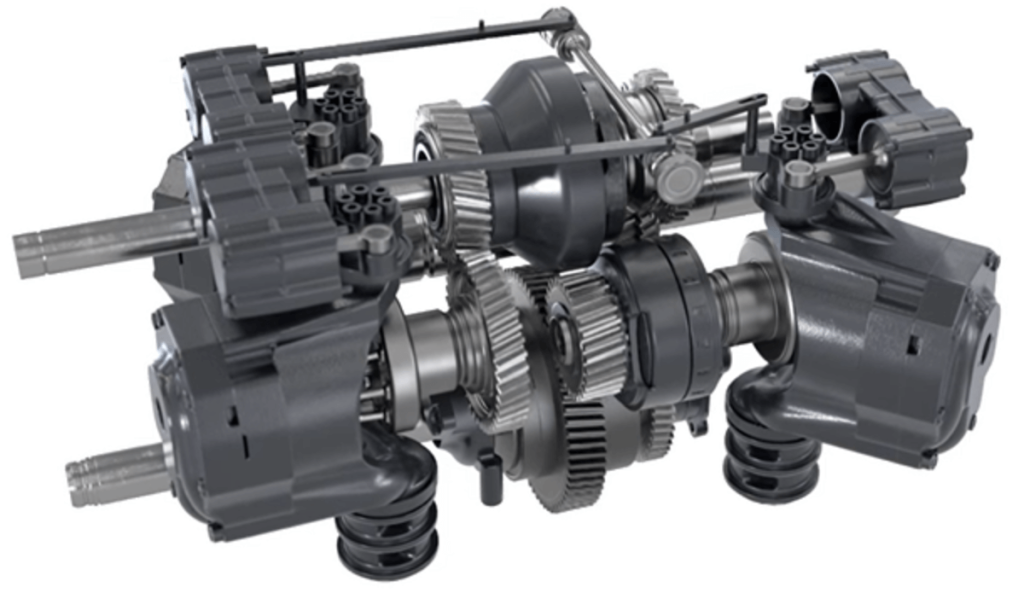

The shift between gears is realized through gear meshing and clutch switching. Commonly, there are mechanical slip type, synchronizer shift, and variants with power shift function.

Types and differences:

Slip-shift (8×2 / 12×12 / 16×16): simple structure, low cost

Power Shuttle: supports direct back-and-forth shifting without the clutch, improves efficiency

Synchronized Gear Shift with Synchronizer (Syncro): reduces stuck gears, suitable for frequent shifting scenarios

Advantages and highlights:

Direct power output: virtually no loss of energy, high torque. High torque

Mature and reliable structure: easy to maintain in rural service stations

More suitable for: heavy plowing, plowing, furrowing, deep loosening and other tasks that require high pulling force and stability

Limitations and notes on use:

Frequent clutch depressions for starting and reversing, fatigue during long hours of operation

Not friendly enough for newcomers to operate

Unsuitable for: frequent starting and stopping or fine work in a small area

✅ MINNUO case: deep plowing user in Shandong area selects the 16+8 geared The average daily operating efficiency has been increased by 17%, and the transmission system has not been overhauled in 5 years.

1.2 Hydrostatic Transmission (HST)

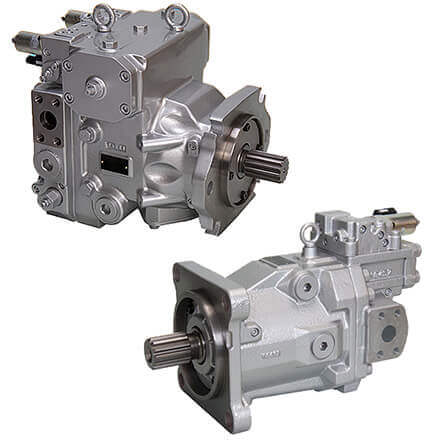

Working Principle Explanation:

The hydraulic pump drives the hydraulic motor to form a closed circuit, which realizes the effect of “stepless speed change” by adjusting the flow of oil without the need of shifting clutch.

Technical features:

Continuously adjustable speed control, no stuttering

Commonly used in orchard machines and small maintenance tractors with low horsepower (25~60hp)

Advantages and highlights:

Flexible control, suitable for novices and female drivers

Particularly suitable for: frequent switching back and forth (e.g. spraying/loading) or low-speed cruising operations

No need to step on the clutch: reduces wear and tear on the machinery, and improves operational safety

Cautions and shortcomings:

Energy conversion efficiency is lower than that of Gear drive (about 85%-90% vs. 95%-98%)

Oil temperature management is needed under long-time high-temperature operation to prevent power degradation

Higher maintenance cost, some core components need OEM support

✅ MINNUO Orchard HST series: excellent feedback in vineyards, kiwi orchards and other delicate operation scenarios, and the daily workload of a single person has increased by 25% compared with the same period of the previous year.

2.Performance Comparison: Gear vs. Hydrostatic

In the process of tractor drivetrain selection, “Gear vs. Hydrostatic” has always been the focus of farmers and dealers. While each has its own advantages, the real logic of selection should be based on work scenarios + operating habits + cost budget. The following is a comprehensive comparison of six dimensions to help readers make a rational judgment.

2.1 Torque Output (Traction):

Gear: High torque output, transmission efficiency of 95% ~ 98%, very suitable for heavy-duty operations such as deep tilling, plowing, soil loosening, etc., with stable and reliable traction performance.

Hydraulic Hydrostatic: medium to low, due to the existence of hydraulic conversion loss, torque is slightly insufficient under heavy load, long-term heavy-duty operation there is heat, performance degradation and other hidden problems.

✅ Suggestions: mountain terraces, sticky soil, etc. It is recommended to give priority to gear transmission.

2.2 Maneuvering Flexibility (Suitable for Drivers):

Geared Gear: intuitive operation but steep learning curve, high experience requirements for drivers. Frequent clutch presses and gear shifts for long periods of time result in a high level of fatigue.

Hydrostatic: smooth operation, no shift impact, especially friendly to novices and female drivers, suitable for greenhouse planting, orchard spraying and other scenarios that require frequent speed changes.

✅ MINNUO suggests: If you are a cooperative or family farm, we recommend you to choose the hydraulic small horsepower model to improve the control experience.

2.3 Difficulty of care and maintenance:

Gear type Gear: simple structure, easy to overhaul, low maintenance costs. Market parts are common, and can be repaired directly at the countryside repair center.

Hydraulic Hydrostatic: complex structure, the core hydraulic components rely on the original factory support, need to have a certain technical background or rely on after-sales team.

✅ Maintenance recommendation: if you choose HST configuration, it is recommended to match the original remote troubleshooting function or video maintenance kit.

2.4 Applicable operating scenarios:

| Application Areas | Recommended Transmission Forms | Rationale |

| Orchards | HST | Flexible operation, fast repeated turnaround, smooth and labor-saving |

| Field Farming | Gear | Powerful and load-resistant, suitable for long-time operation |

| Lawns/Greens | HST | Excellent low-speed uniformity performance, friendly operation |

| Mountain Slopes | Gear | Strong torque, good effect with differential lock |

✅ MINNUO Case: Feedback from an orchard user in the Philippines, the operating efficiency of the hydraulic small horsepower model with the Cat I electronically controlled sprayer was increased by about 28%.

2.5 Cost considerations:

Geared Gear

Advantage: low initial purchase price, cheap maintenance parts

Cost structure: low maintenance cost after a one-time investment

Hydrostatic

Disadvantage: high initial investment cost (about 15%-25% more expensive)

Cost structure: the need to replace the hydraulic oil, hydraulic pumps in the long term, the need for long-term stability of the supply chain

✅ ROI Recommendation: Orchards, vegetable bases, if the operating area < 50 acres, you can give priority to the hydraulic type; if 100 acres for the operation of Cat I electronic control sprayer efficiency increased by about 28%. 50 acres, can prioritize the hydraulic type; if more than 100 acres of grain and oil base, gear type is more long-term cost-effective.

Comprehensive recommendations: which type of user is suitable for which type of transmission?

| User Type | Recommended Drive Systems | Reasons in brief |

| Township Co-op (rotational) | Geared Gear | Adaptable to heavy plowing, large plots, easy to handle breakdowns |

| Home Orchard / Small Contractor | HST Hydraulic | Easy to maneuver, labor-saving, less burden of frequent startups and stoppages |

| Mountain Grower | Geared Gear | Slip-resistant, strong hill climbing, strong front axle structure |

| Vegetable / Nursery / Seedling Site | HST Hydraulic | Infinitely adjustable speed, good compatibility for docking seeding/sprinkler equipment |

3.Matching Transmission Type to Your Workload

A tractor’s transmission system is not a universal component, but a key “fit for purpose” module. Different work scenarios have different requirements for speed control, shift frequency and power response, so the choice of Gear or HST should closely match the type of work and intensity of use.

3.1 Heavy Duty + Large Field High Intensity Tillage: Choose Gear

Applicable Scenarios:

Long Distance Rotary Tillage

Deep Pine/Plow Tillage

Heavy Duty Tillage

Agricultural Products Forwarding or Hauling Multi-Axle Trailer

Recommended Configurations:

✅ Use 4WD All-Wheel Drive Structure + High Torque Multi-Stage Gearbox

Recommended Model: MINNUO 1204 Tractor with 16F+8R Manual Group Shift as standard, which is equipped with excellent traction and hill-climbing performance.

Strong and stable low-speed gears for continuous loads or for pulling on slopes, especially in “high-resistance farming areas” such as Central Asia, Africa and South America.

Advantageous analysis:

High gear transmission efficiency, lower long-term fuel consumption;

Simple maintenance, high popularity of components;

Wider choice of supporting implements (heavy-duty deep turning plows, hydraulic turning plows, livestock transport trailers, etc.).

Case reference:

In the test conducted by the Ministry of Agricultural Machinery of Kazakhstan, the MINNUO 1204 tractor completed a continuous 10-hour heavy-duty transportation task, with stable oil temperature of the engine and transmission, and the average fuel consumption was 11% lower than that of local competitors.

3.2 Orchard nursery + frequent reversing/turning: choose hydraulic continuously variable transmission (HST)

Scenarios:

Precise spraying, pruning and fertilizing in orchard with small row spacing;

Repeated shifting operation in nursery/horticultural crops cultivation area;

High-frequency reversing operation such as turning backward and forward, climbing and other high-frequency reversing operations in narrow field of shed.

Recommended Configurations:

✅ Choose a small horsepower model with HST stepless speed control + zoned hydraulic micro-manipulation system

Recommended Series: MINNUO Orchard Exclusive horticultural tractors, such as the 45hp orchard mini-tractor, with highly responsive foot-controlled steering, low-noise HST drive, and lightweight trailer compatibility.

Advantage analysis:

realize “pedal acceleration + automatic direction change”, freeing hands and reducing clutch and throttle impact;

fine speed control, which is good for stable spraying and precision sowing;

small turning radius + hydraulic power steering, suitable for high-frequency steering scenarios between tree rows.

Case reference:

After using MINNUO Orchard 45hp HST tractor in Nanfeng citrus base in Jiangxi, the spraying efficiency was increased by 28%, the fatigue of man and machine was reduced significantly, and the failure rate was less than 3% at the end of the season.

4.Maintenance and Longevity Considerations

Regardless of whether you choose a geared or hydraulic continuously variable transmission (HST) system, the key to long term stability is systematic maintenance and early warning mechanisms. Maintenance priorities vary from drivetrain to drivetrain, and neglecting these details often results in significantly shorter life and higher repair costs.

4.1 Maintenance Key Points of Gear Transmission

Gear transmission mechanism has strong structure and high transmission efficiency, but long-time operation will easily lead to oil oxidation, gear wear and clutch plate fatigue, which need to be maintained according to the cycle.

✅ Suggested maintenance intervals:

Gear oil change: change gear oil every 500-600 hours, use API GL-4 or GL-5 high pressure gear oil.

Clutch plate inspection and adjustment: check the thickness of friction plate every 300 hours to prevent slipping or abnormal noise.

Gear mesh clearance inspection: analyze tooth contact marks once every six months to warn of abnormal gear wear.

✅ Problems that are easily overlooked:

Multi-shift mechanism is prone to dust accumulation and jamming, it is recommended to cooperate with the operation of “blowing cleaning + oil mist maintenance”;

Manual shift is prone to wear of synchronizer due to long-term misoperation (not fully depressing the clutch).

4.2 Maintenance Points of Hydraulic Continuously Variable Transmission (HST) System

The pump body, motor and control valve of HST structure are high-precision parts, which are significantly affected by the purity and temperature of the fluid, so the hydraulic circulatory system needs to be monitored.

✅ Key Maintenance Items:

Oil Temperature Monitoring: The temperature should be kept at 40~85°C. Long-term high temperature operation will lead to fatigue of the pump body and aging of the seals; it is recommended to install an HST temperature control alarm.

Hydraulic oil replacement: Replace HST special oil every 300~400 hours, use ISO VG 46/68 viscosity grade oil.

Filter element replacement and cleaning: Hydraulic oil return filter element is recommended to be replaced once every 250 hours to prevent particles from clogging and causing system pressure instability.

Pump/Motor Life Monitoring: It is recommended to use “Pump Frequency Vibration Monitoring” or “Working Time Counter” to determine the fatigue of components.

✅ Tips on misuse:

Common misuse: Frequent switching of direction back and forth within a short period of time (e.g., not returning to the center position) will lead to impacts on the hydraulic valves and shorten their life span;

Problem of oil mixing: HST needs special anti-foam and anti-shear hydraulic oil, and should not be mixed with ordinary gear oils or hydraulic oils.

4.3 MINNUO Standardized Maintenance Tools and Service Support

In order to help users around the world to reduce the threshold of maintenance, MINNUO provides the following supporting services for different transmission systems:

Digital Maintenance Manuals: Quickly check the maintenance nodes and common trouble shooting solutions with QR code;

Early fault diagnosis system: HST series comes standard with “main pump temperature + hydraulic pressure” dual-channel abnormality alarm;

Remote Maintenance Guidance Platform: After users upload operation data through MINNUO App, the system automatically generates the next round of maintenance recommendations and risk prediction.

Three-year warranty on key components and fast parts supply mechanism: guarantees global delivery of consumable parts such as clutch plates, filter elements, oil seals, etc. within 72 hours.

5.Real-World Case Studies

Theoretical judgments are important, but practical results are the real test. In this section, through the experiences of MINNUO global customers in different farming scenarios, we will demonstrate in depth the performance and user feedback of the two types of transmission systems, the geared type and the hydraulic continuously variable speed (HST), in actual work.

Case 1: Shandong, China, field operation: gear type is more stable

Background:

Terrain: mainly plains, with continuous cultivation, suitable for high load dragging operation;

Crop type: wheat, corn;

Main operations: plowing, deep-pine, rotary tillage and transportation.

User feedback:

“We use a MINNUO 100hp gear tractor with 16F+8R transmission with 4WD chassis, which has clear shifting and powerful transmission in the fall plowing stage, not only with great traction, but also with deep plowing and high efficiency. Even under multi-hour operation, the engine and transmission temperatures are well controlled.”

Summary highlights:

With the geared transmission, the machine has stable traction and lower fuel consumption;

Lower maintenance costs afterward, with only routine oil changes and clutch plate inspections required.

Case 2: Italian vineyards use HST manipulation to improve efficiency

Background:

Terrain: hillside vineyard area, small turning radius;

Crop type: red and white grapes;

Main operations: orchard management, dosing, fertilizer application.

User feedback:

“The MINNUO Orchard HST tractor is particularly flexible when working under the grapevines, and it can easily realize a small turnaround in front and back, and the hydraulically-controlled transmission system allows us to work without stepping on the clutch, which improves the continuity of the work a lot. The HST is a much better choice for our scenario, which requires frequent starting, stopping and speed adjustments.”

Summarizing the highlights:

The hydraulic system realizes truly stepless speed change, which saves energy and is easy to get started;

It is suitable for high-frequency operation and precise work in orchards and other scenarios, and significantly reduces the driver’s fatigue.

Case Study 3: Hilly Vegetable Gardens in the Philippines: Mixed Recommendation

Background:

Terrain: hilly, planting peppers and eggplants;

Main operations: loosening soil, transporting, applying medicine.

Solution:

adopts front axle 4WD + geared transmission to provide sufficient traction, and

is equipped with HST control module for precise speed regulation in the orchard section.

Customer comment:

“MINNUO’s customized configuration is really thoughtful. The geared transmission for transportation is powerful and fuel efficient, and switching to HST control in the middle of the operation is more convenient, especially for field turning and spraying.”

Case 4: Turkish Wheat Cooperative: Prioritizing Cost-Effectiveness

Background:

The cooperative has a total of four MINNUO geared tractors, with power ranging from 90 to 110hp;

Mainly used for spring sowing and fall harvesting, with concentrated operating hours;

More than 1,000 hours of operation per year.

Maintenance feedback:

Gear-type structure is sturdy, low frequency of clutch plate replacement;

Maintenance is based on oil change, sufficient spare parts, and no breakdown downtime.

Conclusion

Every transmission system has its optimal purpose—not all fields, tasks, or drivers are created equal. Gear transmissions offer robustness and traction for heavy-duty tillage or long-haul operations, while hydrostatic systems (HST) deliver unmatched precision and ease of use, especially in orchards, nurseries, and tasks with frequent speed or direction changes.

Ultimately, choosing the right transmission is less about upfront cost and more about long-term fit, productivity, and driver efficiency. Instead of defaulting to tradition or the cheapest option, evaluate what truly suits your terrain, workload intensity, and operator skill level.

MINNUO offers dual-platform customization—gear-driven or HST—tailored to your region, usage needs, and labor context. Whether you’re cultivating wheat in wide plains or maneuvering through vineyard rows, our specialists will recommend a system that optimizes power, control, and ROI.