Sprayers are indispensable tools for modern farming, ensuring that crop protection products are applied accurately and efficiently. Whether you’re working with herbicides, fungicides, or fertilizers, a well-prepared and properly set-up sprayer is critical—not only for maximizing product performance, but also for ensuring the safety of operators, bystanders, and the environment. This article explores six essential steps to prepare your sprayer before the busy season, covering everything from visual inspection and nozzle testing to PPE checks and system pressure verification.

So, why is correct sprayer setup so important? Simply put, because small mistakes can lead to big problems. Inadequate maintenance or improper calibration can reduce spray accuracy, damage equipment, waste chemicals, and compromise operator safety. Meanwhile, today’s precision agriculture tools—from GPS-guided booms to flow control systems—require a solid foundation to perform at their best. Ensuring that your sprayer is clean, leak-free, and running at the right pressure helps avoid delays, protect your crops, and comply with regulations like NSTS certification.

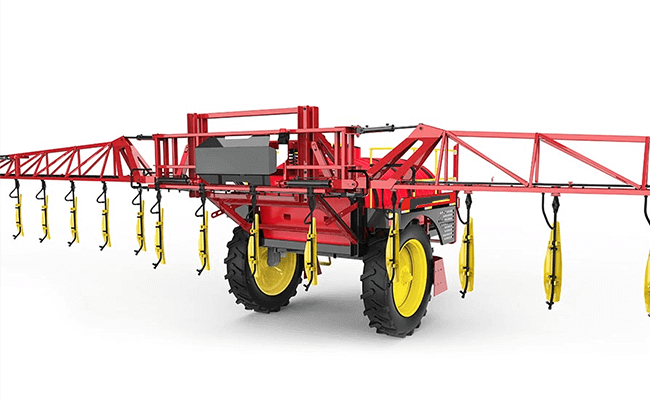

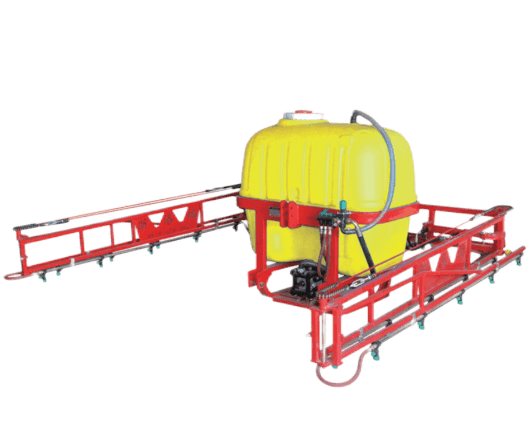

Curious whether your boom arms are properly balanced? Wondering how nozzle wear might affect your spray pattern? This guide answers those questions and more, helping farmers across all scales—from row crop operations to specialty growers—optimize their spraying performance. With farm machinery key components such as sprayer maintenance, tractor-mounted sprayers, nozzle calibration, and PTO systems becoming central to high-yield strategies, this practical checklist helps you work smarter—not harder. And if you’re looking for reliable agricultural equipment that meets real-world demands,MINNUO’s professional farm machinery solutions are always a choice worth trusting.

Contents

1. Visual Inspection: Look Before You Spray

Getting your sprayer ready for the season isn’t just a routine task—it’s a critical step toward effective crop protection, operator safety, and long-term equipment reliability. Whether you’re gearing up for spring spraying or transitioning between crop cycles, setting up your sprayer correctly can make the difference between smooth operations and costly downtime. Below, agronomist George Baxter walks us through six essential steps every farmer should follow for a trouble-free spraying season.

Before even thinking about chemicals or calibration, start with a thorough visual inspection of your sprayer. Pull it out of storage and go over every inch—check the tank, filters, hoses, and electrical components. Look closely at perishable rubber parts like drip control valves and examine solenoids for any water ingress, which can be a sneaky culprit in system failures.

Don’t forget the basics: inspect PTO guards, boom joints, lights, and tires for wear or damage. And if your sprayer is due for its NSTS (National Sprayer Testing Scheme) certification, now’s the time to book that test.

Common issue solved: Catching problems early prevents delays when weather windows are tight.

2. Get Your Tyres in Check

Tyre pressure might not seem like a spraying issue—but it plays a big role in boom stability and tramline compaction. Uneven or incorrect pressures can cause unnecessary boom bounce, even on self-levelling machines.

Check both sprayer and tractor tyres. Use manufacturer guidelines or consult your tyre rep to find a pressure that balances road use with field performance.

Tip: Use lower pressures for wet fields to reduce compaction, but make sure they’re safe for road travel.

3. Clean and Empty the Tank (Again)

Even if your sprayer was cleaned before storage, it’s worth flushing the tank again with fresh water. This not only removes residues but helps you spot leaks in seals and connections.

For sprayers used with sulfonylurea or other potent chemicals, consider using a tank cleaner—even if the label doesn’t require it. This extra step can protect sensitive crops and avoid contamination.

Reminder: Never dump washings onto open ground—use a biobed or designated disposal system.

4. Leak Check at Operating Pressure

After cleaning, run clean water through the system and pressurize it to at least 5 bar. Check for leaks around hoses, nozzles, and valve assemblies. Make sure your gauges or electronic pressure readings are functioning correctly.

This is a great moment to verify that anti-drip valves and solenoids are opening and closing as they should.

Problem solved: Mid-season breakdowns due to a $2 O-ring are easily avoided with this simple step.

5. Nozzle Testing and Performance

Nozzles are the business end of your sprayer, and worn or blocked ones can ruin an application. Jug-test them to ensure they deliver accurate rates and inspect for damage or clogs.

Also consider whether your current nozzle type is suited to your crop and water volume. Many farmers are using lower spray volumes for efficiency—but if coverage is suffering, it might be time for a rethink.

Ask yourself: Are you prioritizing field speed over product performance? Discuss with your agronomist for tailored advice.

6. Personal Protective Equipment and First Aid

Don’t overlook operator safety. PPE must include gloves, spraying overalls, and a face mask as a minimum. A first-aid kit with eyewash, a spill kit, fire extinguisher, and an accident response plan should be standard kit on any sprayer.

Post these protocols in the cab or shed so everyone on your team knows what to do in an emergency.

Why it matters: Investing a few minutes in prep can save lives, avoid fines, and reduce insurance claims.

Conclusion: Prep Now, Save Later

In the rush of the spring spray season, taking time for setup might feel like a delay—but it’s a delay that pays off. By following these six essential steps—checking equipment, adjusting tyre pressure, cleaning the tank, inspecting for leaks, testing nozzles, and reviewing safety gear—you lay the groundwork for precise application, minimized downtime, and safe fieldwork. It’s not just about compliance or performance—it’s about protecting your crops, your team, and your investment.

As agricultural machinery continues to evolve, the importance of working with dependable tools and expert support becomes even more critical. For farmers looking to elevate their spraying operations with reliable equipment and service guidance, MINNUO Agricultural Machinery’s professional services are worth choosing. With precision-focused tools and a deep understanding of real-world farm needs, Mino is committed to helping growers get the most out of every spray pass—safely, efficiently, and effectively.