Selecting the right cultivator in farmland management significantly boosts operational efficiency and directly impacts soil quality and crop yield. When faced with various types of cultivators, you might wonder: which one best suits your land? What are the differences between the models? The functions, terrain suitability, and pricing of different cultivators play a crucial role in determining their specific applications in agricultural work. Understanding how each type of cultivator can help you manage your fields more efficiently is key.

Many users encounter practical issues when choosing a cultivator. For example, some fields require deep tilling, while others are better suited for shallow soil loosening. Large farms need efficient and durable equipment, while smaller farms benefit from lightweight and flexible options. Factors like budget, terrain complexity, and soil type can all influence the final decision. Knowing the functions and applications of each type of cultivator is essential to finding an option that meets your needs and stays within budget.

This article will analyze the roles, advantages, and disadvantages of different cultivator types and provide practical purchasing advice to help you quickly find the best type of cultivator. Whether you’re a small farm owner or a procurement specialist for a large agricultural enterprise, this guide will help you make a more informed choice for easier and more efficient farming.

Contents

Basic Definition and Function of Cultivators

A cultivator is an agricultural tool specifically designed for loosening soil, removing weeds, and preparing the ground before planting. Typically mounted on tractors, it uses tines or blades to dig into the soil, helping to aerate it, break up clods, eliminate weeds, and mix in fertilizers or soil amendments, creating optimal conditions for planting. Depending on the application and farm size, cultivators range from small, manually operated units to large, gas- or electric-powered equipment.

In recent years, as global agricultural mechanization continues to advance, demand for cultivators has grown steadily. According to market research firm Technavio, the global cultivator market is projected to expand and increase in value by approximately $300 million between 2020 and 2024. This trend highlights the strong demand from farmers worldwide to improve cultivation efficiency.

Different Types of Cultivators and Their Specific Uses

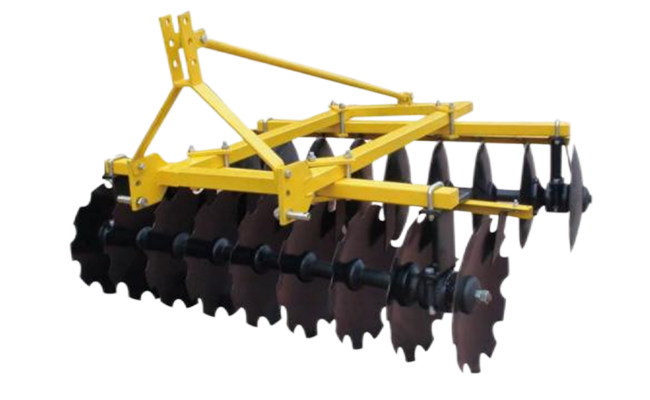

Disc Harrow: Preparing Soil for Large Farmlands

A disc harrow, composed of a series of metal discs, efficiently cuts into the soil and loosens the top layer, making it especially suitable for large-scale farmland. Each disc is angled to penetrate the soil up to 8 inches, breaking up clods and removing weeds. Disc harrows are commonly used both before and after primary tillage to ensure a loose, even soil structure.

Application

Disc harrows work well on large farms and extensive fields, particularly for weed removal and soil loosening. Minnuo’s Model 3009, with a width of 29.6 feet, provides excellent cutting performance, making it ideal for post-harvest weed clearing and preparing the land for the next planting cycle.

Chain Harrow: Ideal for Seedbed Preparation

A chain harrow is a precision tool used mainly for preparing seedbeds before planting. With a series of small teeth and chains, it breaks up clods left by disc harrows, leaving the ground smooth and level. The curved tines help distribute soil evenly, enhancing aeration and water infiltration.

Application

Chain harrows are ideal for the final leveling of seedbeds, creating a smooth surface for seeds. Minnuo’s Model 4614 can also pair with seeders, streamlining the soil preparation process before planting.

Offset Disc Cultivator: Ideal for Secondary Tillage

The offset disc cultivator serves secondary tillage tasks, helping farmers further improve soil structure after primary tillage. The independently adjustable discs allow for consistent tilling depth, even on uneven terrain, ensuring a level seedbed for planting.

Application

Offset disc cultivators excel in post-harvest soil preparation and seedbed refinement. With independently moving discs, they achieve uniform tillage, ideal for loosening soil and incorporating crop residues into the top layer.

Spring-Tooth Cultivator: Reducing Soil Compaction and Protecting Crops

Featuring flexible steel tines arranged closely together, the spring-tooth cultivator provides a degree of elasticity when penetrating soil. This design minimizes soil compaction, making it suitable for softer or lighter soils, where it effectively breaks up clods without damaging crop roots.

Application

Spring-tooth cultivators adapt to various soil types and are especially useful for weed and residue management during seedbed preparation. For farmers looking to improve soil aeration and moisture retention in a single pass, this is an ideal choice.

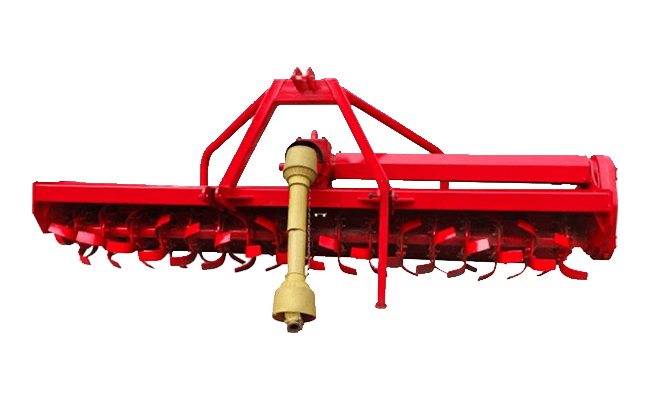

Rotary Tiller: Deep Tillage with Fine, Uniform Results

Equipped with rotating blades or drums, a rotary tiller can reach depths of up to 12 inches, providing deep soil loosening and creating an even planting layer. Used primarily on large farms, it prepares the soil to optimal looseness, making it suitable for crops with deeper root systems.

Application

Rotary tillers work exceptionally well for crops needing deep tillage and precise soil conditioning, such as root vegetables. Minnuo’s line of rotary tillers is tailored to handle various soil structures, meeting the needs of diverse farming operations.

How to Choose the Right Cultivator

Selecting the right cultivator not only boosts tilling efficiency but also improves soil structure, creating an ideal growing environment for crops. Here are key factors to consider when choosing a cultivator:

Tilling Depth: Choose Based on Soil Needs

The depth of tillage directly affects soil aeration, root space, and nutrient distribution. Typically, shallow tillage works well for aerating the soil surface and managing weeds, while deep tillage can effectively improve soil structure, especially for hard soils.

- Shallow Tillage (3-6 inches): Ideal for lightly loosening the surface soil, using equipment like lightweight cultivators or chain harrows. Shallow tilling helps improve aeration, promotes water infiltration, and removes surface weeds.

- Moderate Tillage (6-10 inches): This depth penetrates deeper, making it suitable for mixing in fertilizers or compost. Offset disc cultivators work well for moderate tillage, where deep soil loosening is needed without disrupting the soil’s surface structure.

- Deep Tillage (10-12 inches or more): Suitable for areas that need thorough soil loosening, such as hard or compacted land. This depth works well for crops with deep roots or for soil amendments in the tilling season. Rigid tine cultivators and rotary tillers make ideal choices for deep tilling.

Farm Size: Match Power and Working Width to the Land Area

The size of the farmland determines the power and width required for the cultivator. Selecting a suitable cultivator based on the plot size ensures efficient work without unnecessary costs.

- Small Plots (1-5 acres): Lightweight, handheld, or small cultivators work well, as they are easy to operate and fuel-efficient. For small areas, chain harrows and light rotary tillers meet tilling needs while minimizing maintenance.

- Medium Plots (5-20 acres): Medium-powered cultivators, such as small pull-behind cultivators or mid-sized disc harrows, provide the needed balance of power and efficiency on medium plots. Choosing a model with appropriate horsepower and width can improve productivity.

- Large Plots (20 acres and above): High-horsepower, wide equipment like large disc harrows or heavy rotary tillers work best for large areas, allowing quicker coverage and reducing working time, thus increasing productivity.

Soil Type: Select Equipment Based on Soil Texture

Soil type affects tilling difficulty and equipment choice. Soft soil, hard soil, or rocky soil each requires different types of cultivators to ensure effective tilling and extend equipment life.

- Soft Soil: Heavy-duty equipment ensures adequate depth and soil loosening. Rotary tillers and rigid tine cultivators work well on soft soils, helping with deep tilling and nutrient cycling.

- Hard Soil: Strong-toothed cultivators like rigid tine cultivators suit hard soils, where breaking up clods effectively prevents soil compaction.

- Rocky or Obstructed Soil: Lightweight equipment like spring-tooth cultivators is more effective on rocky soil. Lighter cultivators avoid jamming on rocks and reduce wear and tear. The spring-tooth design handles surface obstacles, ensuring smooth tilling.

Crop Type: Select Tilling Depth Based on Crop Root Needs

Different crops require various tilling depths and soil looseness, so choosing a cultivator based on crop type enhances tilling efficiency and provides an optimal soil environment for crops.

- Shallow-Rooted Crops (e.g., wheat, corn): These crops require loose, aerated surface soil, best handled with shallow or moderate tillage tools like disc harrows or chain harrows. These cultivators ensure soil aeration and prepare seedbeds before planting.

- Deep-Rooted Crops (e.g., potatoes, carrots): These crops need deeper tilling, making rotary tillers or rigid tine cultivators suitable choices. Deep tilling allows ample root space, aiding nutrient and water absorption.

- Tuber Crops (e.g., potatoes, sweet potatoes): Tuber crops benefit from deep-soil loosening with rotary tillers, which create an ideal growth environment by reducing resistance around the tubers in the soil.

Why Choose Minnuo Cultivators?

Minno offers a wide range of cultivators, from lightweight models to heavy-duty options, designed to handle various soil types and tilling needs. Whether you need basic tilling or deep soil preparation, Minno’s equipment delivers. By choosing Minno, you gain:

- High-Quality Equipment: Minno cultivators feature reliable, durable designs built for long hours of efficient operation.

- Versatile Designs: With multiple functional configurations, these cultivators adapt to diverse terrains and tilling requirements.

- Comprehensive Support: Minno provides equipment maintenance and technical support, ensuring your cultivator stays in top working condition.

Conclusion

Choosing the right cultivator can significantly streamline your agricultural operations. Minno’s diverse cultivator lineup helps increase productivity and ensures high-quality soil preparation. With the insights in this guide, you can better understand the features and applications of various cultivators, making it easier to choose the right equipment to maximize your tilling efficiency and achieve optimal results.